A complete treatment device and method for low-temperature thermal conditioning and anaerobic biogas production of sludge

A complete set of treatment and treatment device technology, applied in the direction of sludge treatment, biological sludge treatment, waste fuel, etc., can solve the problems of long residence time, large area of facilities, slow hydrolysis rate, etc., to improve dehydration performance and safety High performance and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

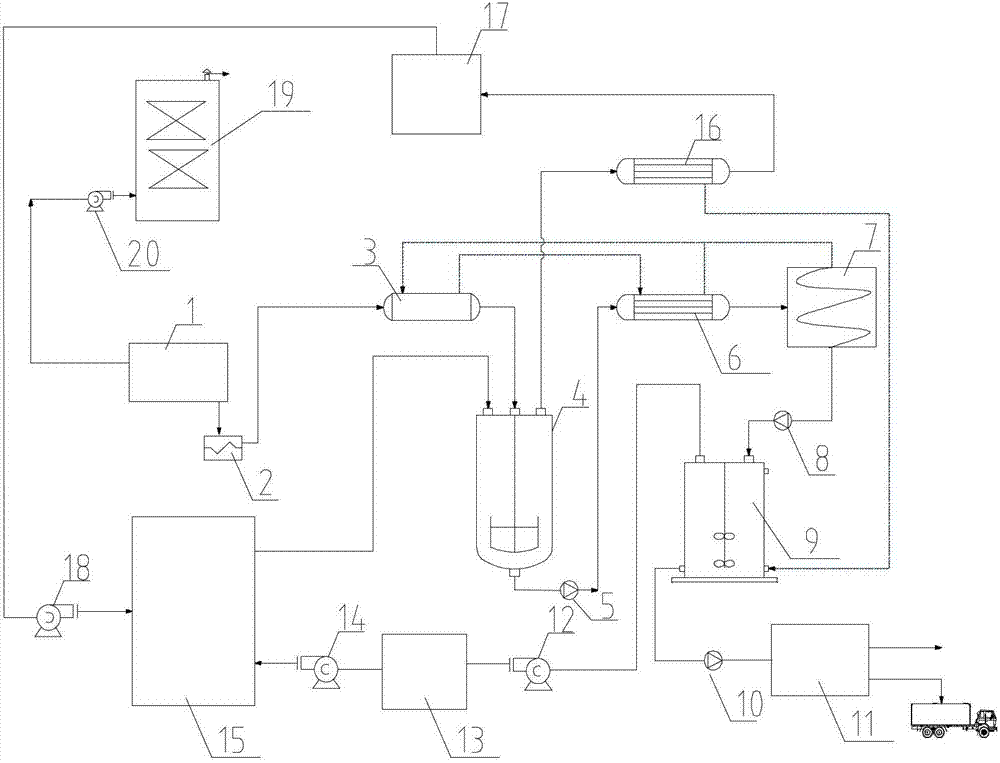

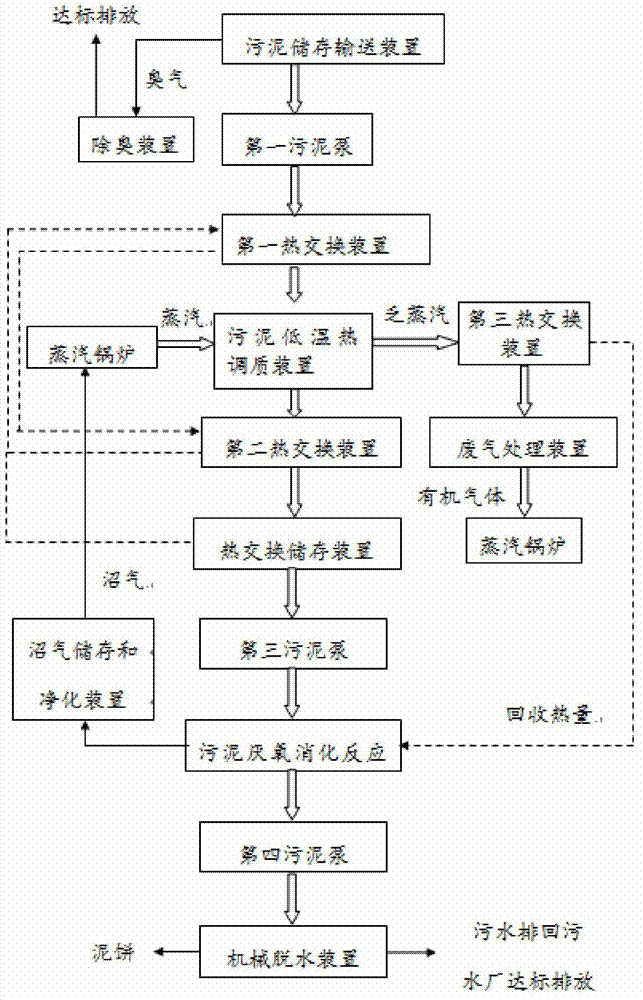

[0028] Such as figure 1 A complete treatment device for sludge low-temperature heat-conditioned anaerobic biogas production is shown, including a sludge storage and conveying device 1, a sludge low-temperature heat-conditioned device 4, a sludge anaerobic digestion device 9, and a first sludge pump 2 , the second sludge pump 5, the third sludge pump 8, the fourth sludge pump 10, the first heat exchange device 3, the second heat exchange device 6, the third heat exchange device 16, the first induced draft fan 12, the first Second induced draft fan 14, third induced draft fan 18, fourth induced draft fan 20, exhaust gas treatment device 17, sludge heat exchange storage device 7, deodorizing device 19, mechanical dehydration treatment device 11 and steam boiler 15.

[0029] The top of the sludge low-temperature thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com