Lifting travelling device and reversed loader using lifting travelling device

A traveling device and loader technology, which is used in slitting machinery, propulsion, earth-moving drilling, etc., can solve the problems of high labor intensity, low work efficiency, difficulty in overall self-moving and lifting functions, etc., to reduce frictional resistance, reduce The effect of running intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

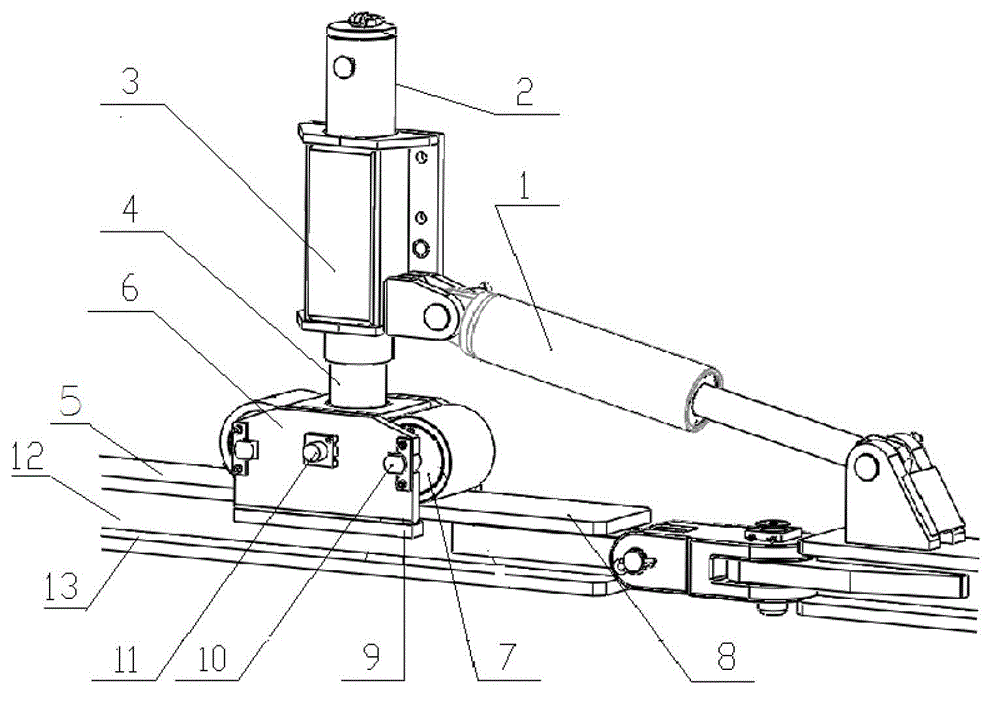

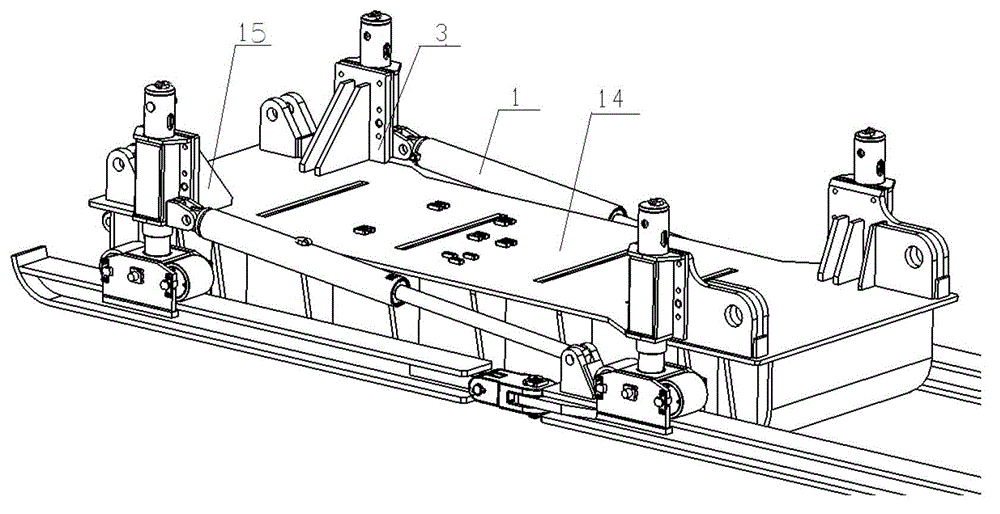

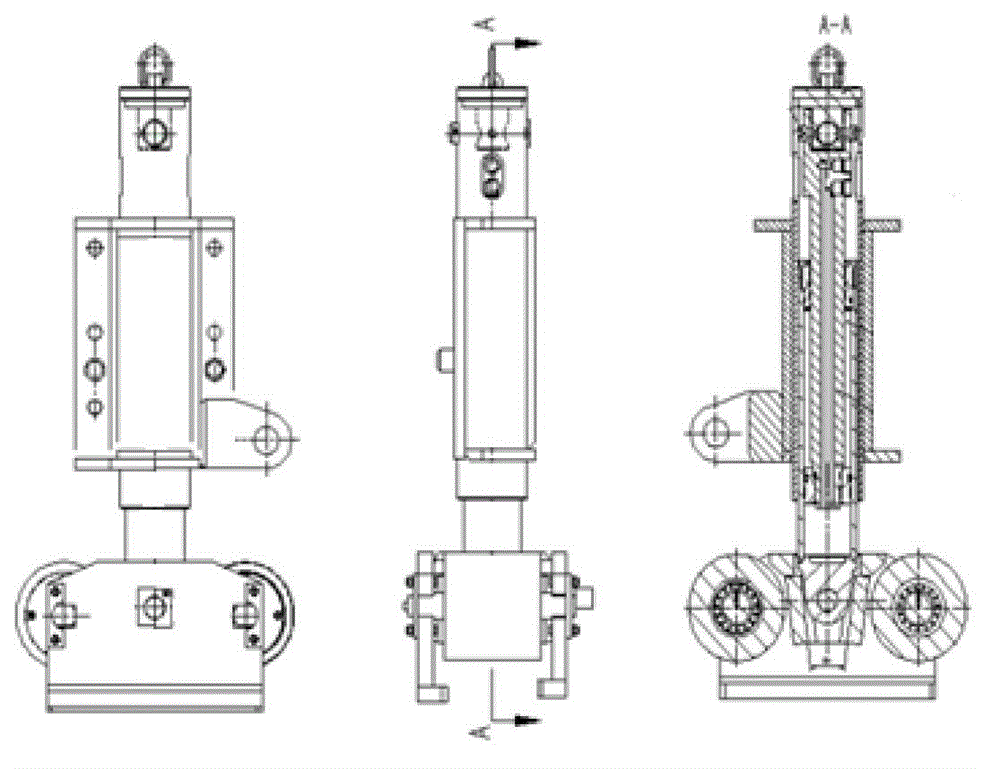

[0019] Such as Figure 1 to Figure 3 Shown, a kind of novel lifting walking device that the present invention provides, this device mainly comprises several parts of base, lifting jack, guide frame, telescopic jack, and walking guide rail.

[0020] The base 14 is arranged on the middle part of the lifting and traveling device, and the both sides of the base 14 are respectively symmetrically provided with lifting jacks, telescopic jacks 1 and walking guide rails 8 .

[0021] The lifting jack mainly includes a cylinder body 4 and a piston rod moving in the inner cavity of the cylinder body 4. A piston rod sleeve 2 is fixed on the outside of the piston rod. The piston rod drives the piston rod sleeve 2 to shrink and extend relative to the cylinder body 4. sports. The bottom top of cylinder body 4 is connected with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com