Man hole for sealing head of tube bundle drier

A tube bundle drying and head sealing technology, which is applied in the direction of dryers, drying chambers/containers, etc., can solve the problems of thick thickness, difficulty in taking out, and difficulty in maintenance work, and achieve the effects of convenient use, light weight, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

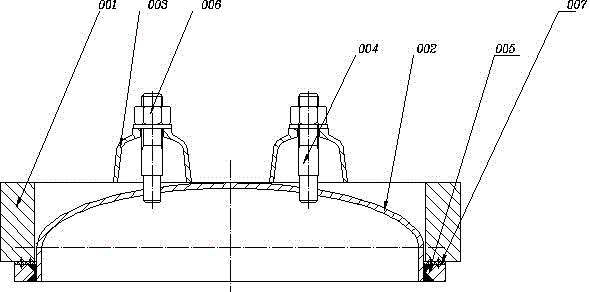

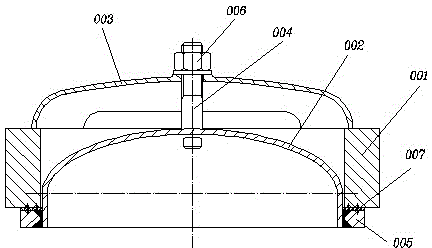

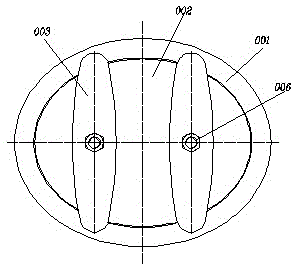

[0011] A manhole for the head of a tube bundle dryer, comprising a manhole ring 001, a head 002, a manhole pressure plate 003, at least one stud 004 arranged at the top of the head 002, and a compression flange 005 arranged at the bottom of the head 002, The head 002 is nested in the manhole ring 002, the compression flange 005 at the bottom of the head 002 cooperates with the bottom of the manhole ring 002, the manhole pressure plate 003 is set on the stud 004 at the top of the head 002, and the manhole The two ends of the pressure plate 003 are mounted on the manhole ring 001, and the tightening nut 006 is set above the manhole pressure plate 003, and tightened downward to make the manhole, the bottom of the 001 and the compression flange 005 tightly sealed, and the head 002 is an egg shape. The manhole pressing plate 003 is an oval eggshell structure. A gasket 007 is arranged between the bottom end of the manhole ring 002 and the compression flange 005.

[0012] The assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com