Method for calibration of optical centering device fixed to base

An optical plummet and base technology, which is applied to instruments, measuring devices, etc., can solve the problems that the plummet cannot be rotated, the centering error can be measured, and it is difficult to guarantee, so as to solve the problem of low accuracy and improve the calibration accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

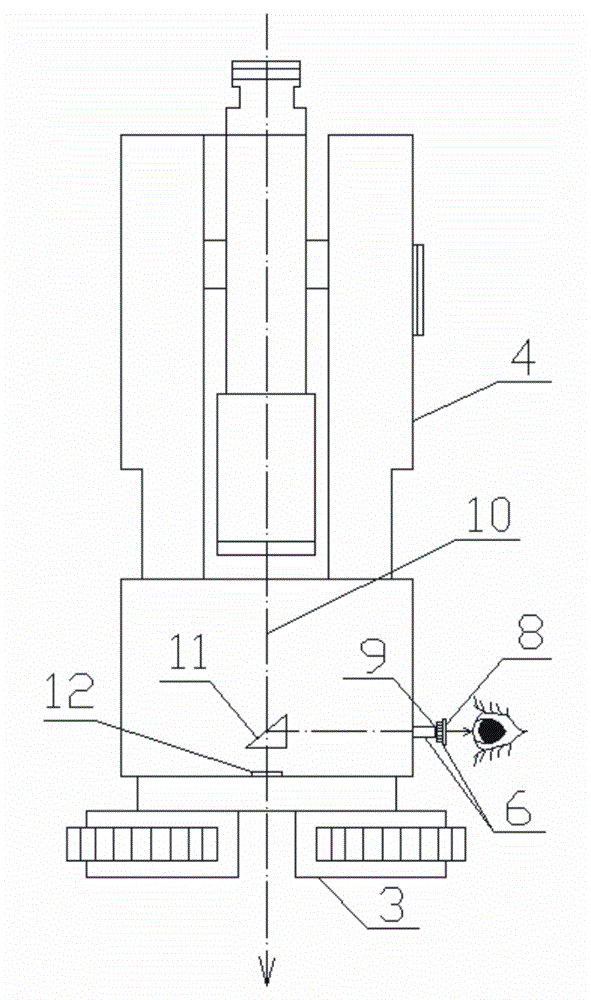

[0017] The calibration method of the optical plummet fixed on the base, the structure of the instrument to be checked is as follows figure 2 shown by figure 2 It can be seen that it includes an aiming part 4, an optical plummet 6, and a base, the aiming part 4 is movably connected to the base, and the optical plummet 6 is fixed on the base, figure 2 It is a schematic diagram of the state during the implementation of the present invention. Depend on figure 2 It can be seen that its calibration method comprises the following steps:

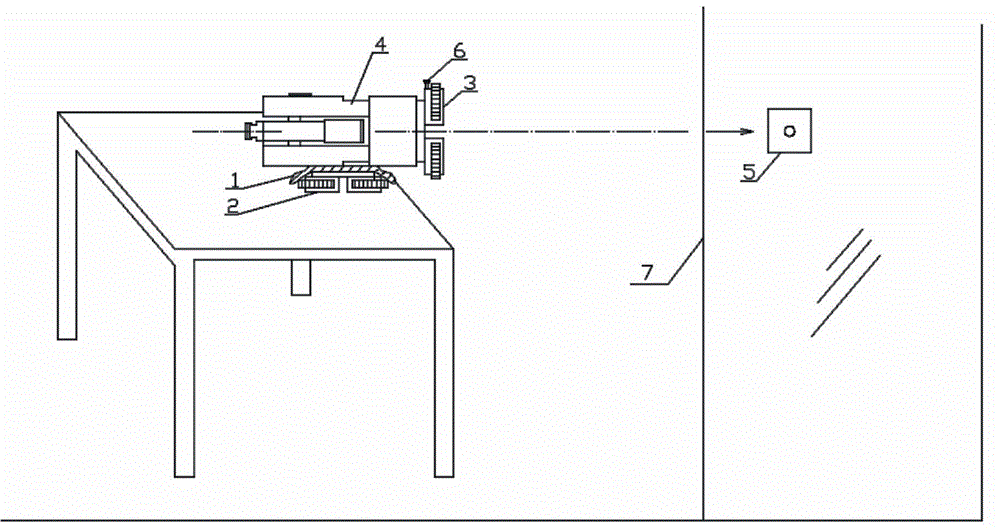

[0018] a. Put the spare base 2 on the edge of the table facing the wall 7, put the rag 1 on the spare base 2, and place the instrument to be tested horizontally on the spare base 2 covered with the rag Above, the function of the rag 1 is to increase the frictional force between the instrument under test and the spare base, keep the aiming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com