Inductive current valley detection method and constant current control method for LED drive circuit

A technology of LED drive and inductor current, which is applied in the field of constant current control, can solve the problems of uncertain and inconstant average current, and the inability to accurately control the average current, etc., and achieve the effect of good constant current and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

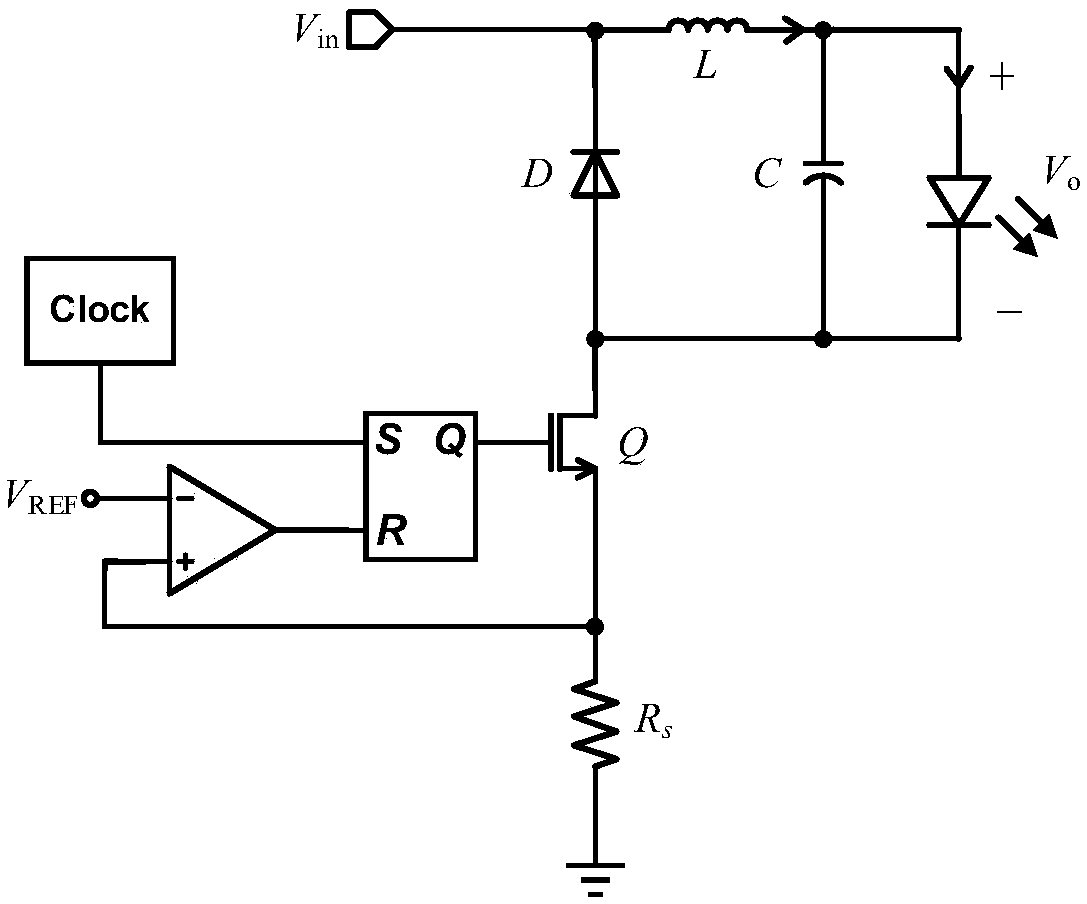

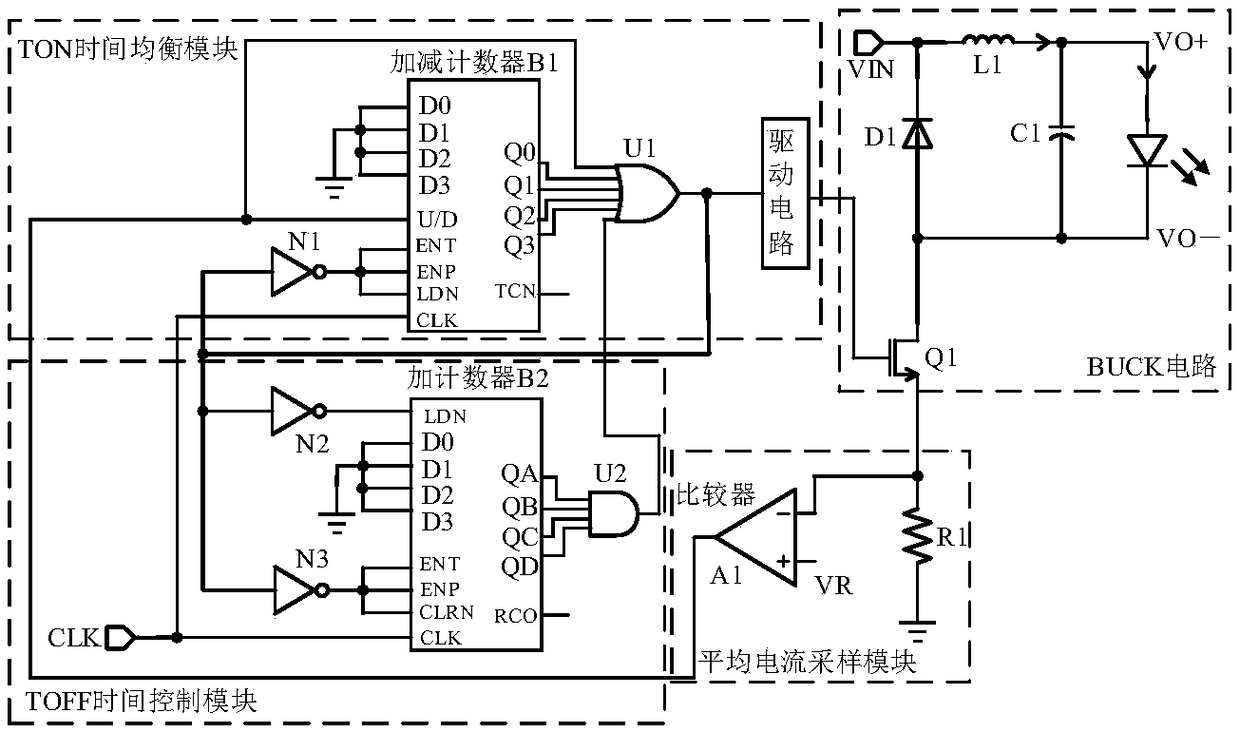

[0037] Such as image 3As shown, the applicable LED drive circuit of the present invention includes a BUCK circuit and an average current sampling module, the average current sampling module includes a sampling resistor R1 and a comparator A1, the negative input terminal of the comparator A1 is used as the input terminal of the average current sampling module and is passed through the sampling The resistor R1 is connected to the ground, and its positive input terminal is connected to the reference voltage VR; the BUCK circuit includes a switch tube Q1, an inductor L1, a diode D1, and a capacitor C1. The inductor L1 and capacitor C1 are connected in series with the diode D1 in parallel with the input voltage VIN and the switch tube Q1. Between the drains, the source of the switch tube is connected to the input terminal of the average current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com