Tube-failing preventing device for doffing tubes of ring spinning machine

A spinning frame and anti-falling technology, applied in textiles and papermaking, can solve the problems of increasing the maintenance cost of the colony, high user requirements, easy damage, etc., and achieve the effects of improving stability and reliability, reducing maintenance costs and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

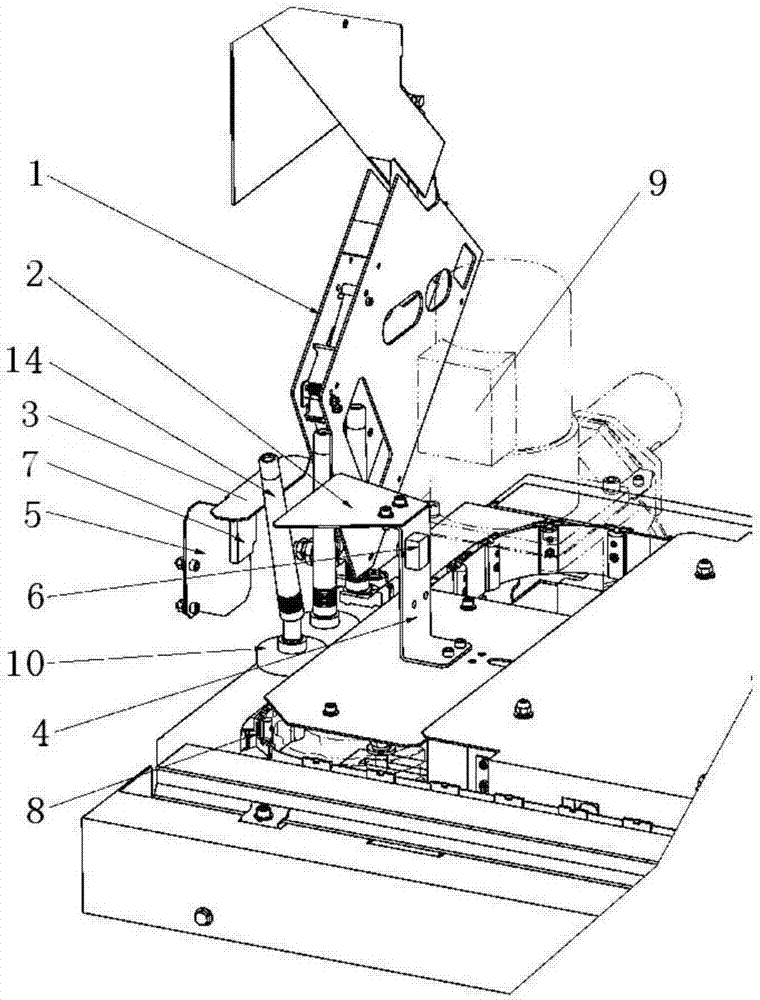

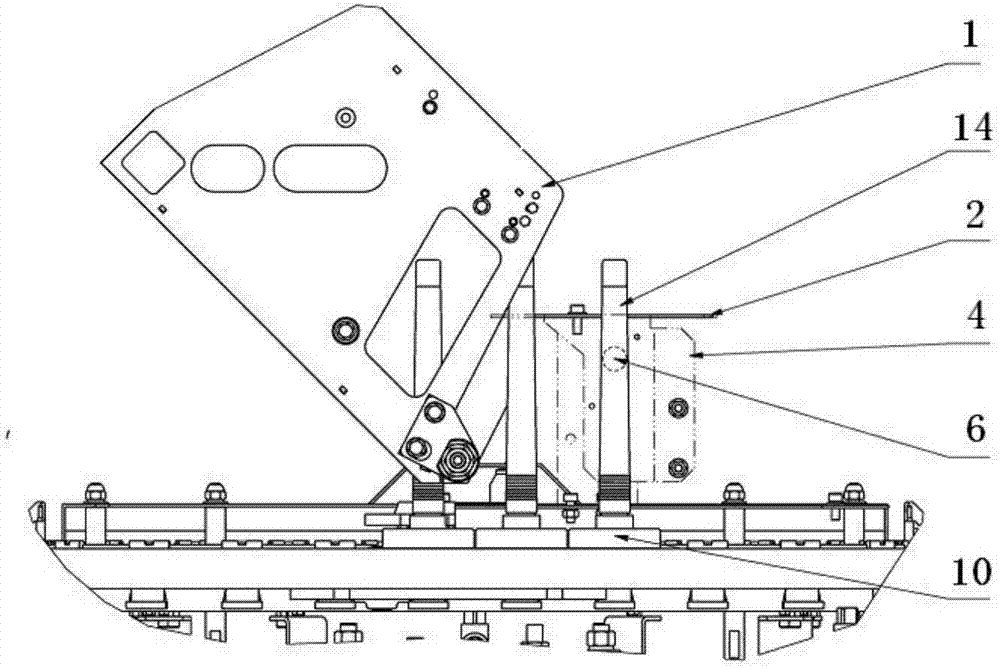

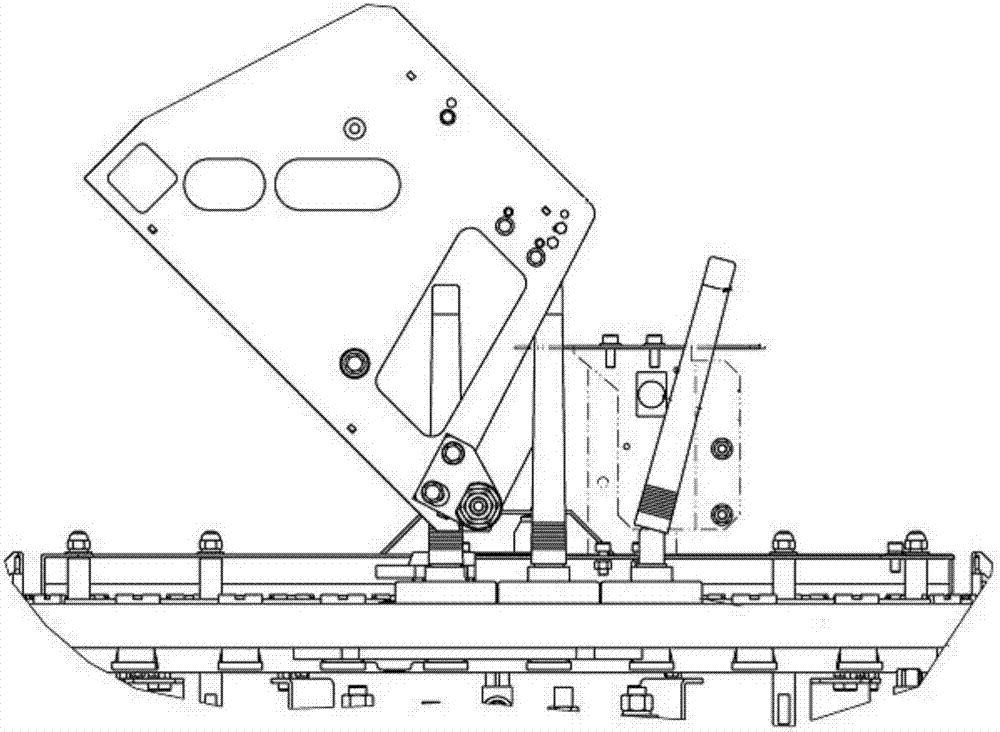

[0012] like figure 1 , a ring spinning frame collective doffing doffing tube anti-falling device, which includes a full tube bin 1, the right side of the anti-falling tube limit plate 2, the left side of the anti-falling tube limit plate 3, a first bracket 4, a second Two supports 5, photoelectric switches 6, reflectors 7, steel strips 8, controller 9 and convex disc 10 are provided with a first support 4 and a second support 5 on both sides of the exit of the doffing tube 14 of the full tube warehouse 1, The limit plate 2 on the right side of the anti-fall pipe is fixed on the first support 4, the limit plate 3 on the left side of the anti-fall pipe is fixed on the second support 5, the limit plate 2 on the right side of the anti-fall pipe and the limit plate on the left side of the anti-fall pipe The positioning plate 3 forms a bobbin limiting area 11 corresponding to the outlet width of the doffing bobbin 14 of the full bobbin bin 1, the photoelectric switch 6 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com