Device for detecting bearing capacity of pile-soil composite foundation

A technology of composite foundation and bearing capacity, which is applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of pressure sensor damage, affecting the measurement accuracy of pressure sensor, and violent collision between force applying parts and lateral bearing brackets, etc., to achieve Effect of reducing impact and mitigating friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

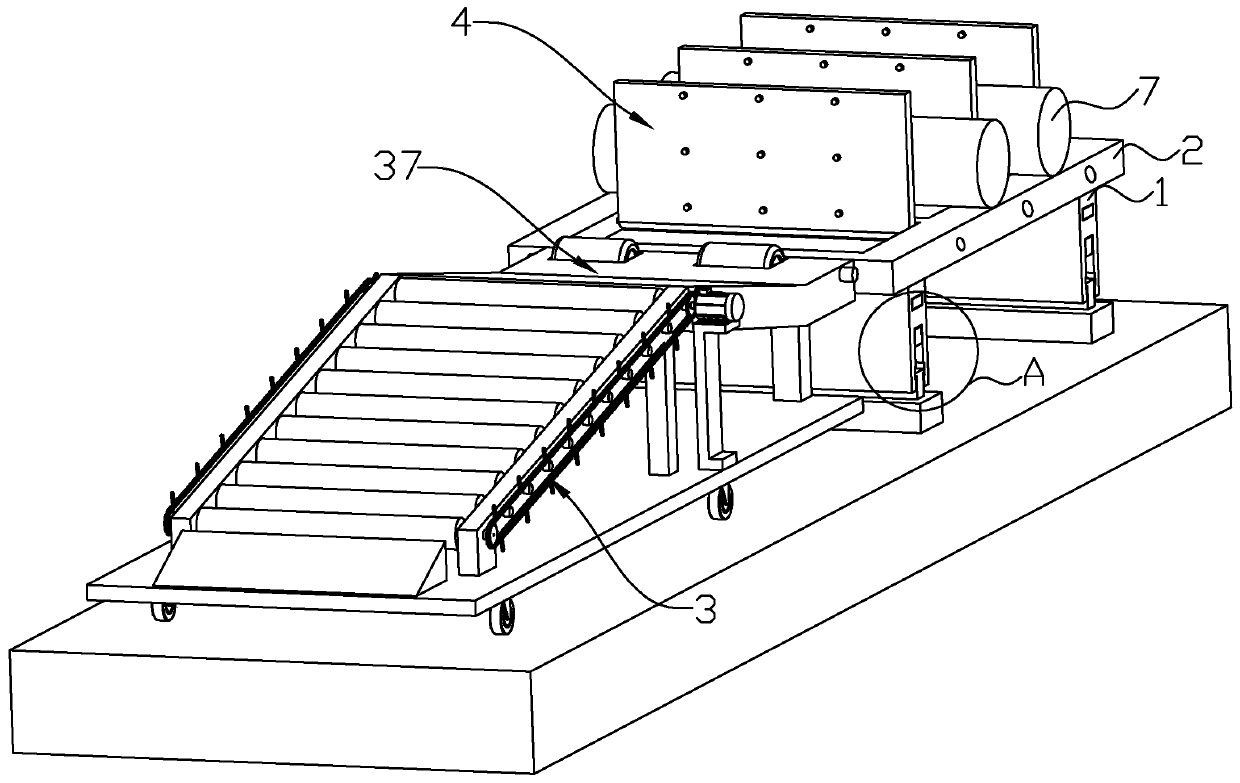

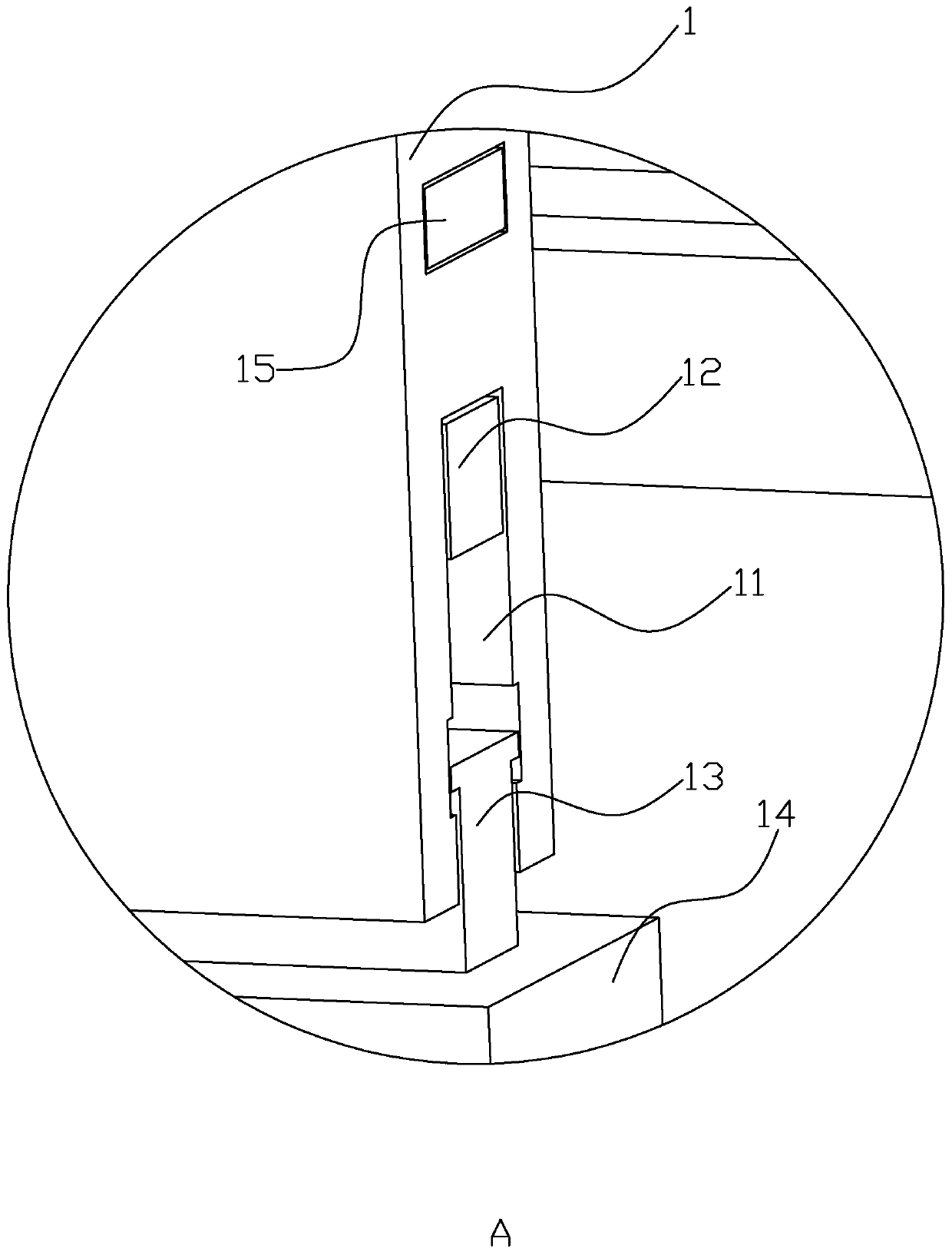

[0035] Embodiment: a kind of device for detecting the bearing capacity of pile-soil composite foundation, such as figure 1 and figure 2 As shown, it includes two longitudinal bearing brackets 1, a horizontal bearing bracket 2 built on the top of the two longitudinal bearing brackets 1, a plurality of installation holes 11 opened in the bottom wall of the longitudinal bearing bracket 1, and a pressure force installed on the top wall of the installation holes 11. The sensor 12 , the movable block 13 installed inside the installation hole 11 , the pressure bearing block 14 affixed to the bottom of the movable block 13 , and the data analysis recorder 15 installed inside the longitudinal bearing bracket 1 .

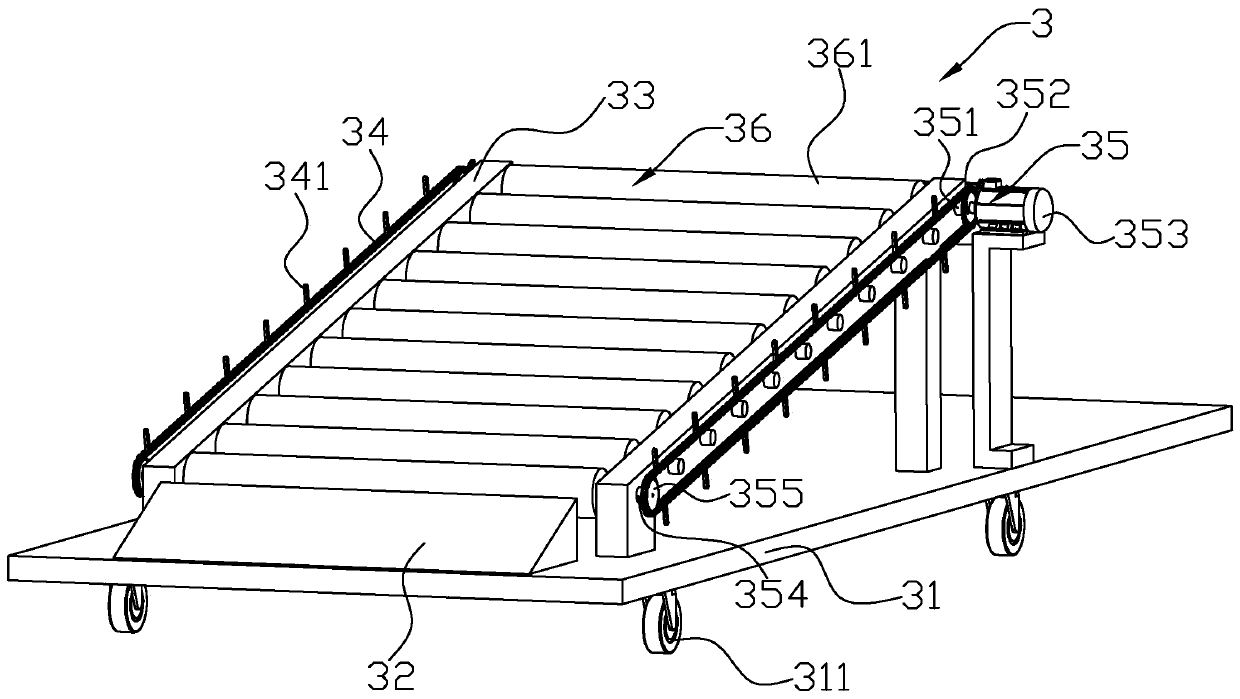

[0036] Such as figure 1 and Figure 4 As shown, a feeding mechanism 3 is installed on one side of the longitudinal bearing bracket 1, and the feeding mechanism 3 includes a frame 31 installed on one side of the longitudinal bearing bracket 1, a feeding rack 33 fixed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com