Transformer radial core column forming device

A forming device and radiation-type technology, applied in the manufacture of inductors/transformers/magnets, parts of transformers/inductors, electrical components, etc., can solve the problems of not being able to form a perfect circle, loose between sheets, electromagnetic noise, etc., and achieve improvement The effective magnetic cross section, the tightness between sheets are satisfied, and the effect of improving the lamination coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

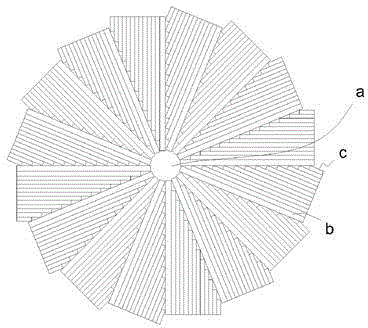

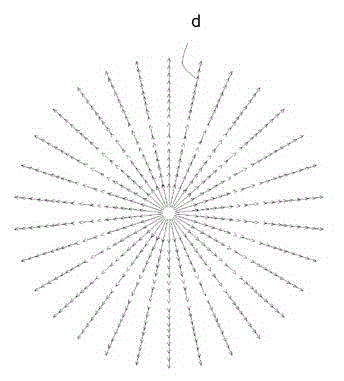

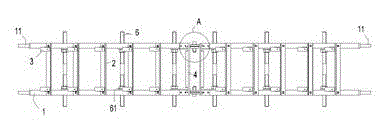

[0035] Generally speaking, the device of the present invention is composed of a mold base, a plurality of cavity plates, two die end plates and multiple sets of sheet pressing components arranged on the mold base. The mold frame is composed of two mold frames which are left-right symmetrical and movably connected at one end of the axial direction; along the length direction of the two mold frames, the multiple mold cavity plates and the two mold cavity plates and the two Die end plate. The middle parts of these die cavity plates all have semicircle recesses, and all these semicircle recesses form the semicircle die cavities that receive silicon steel sheets; the two die end plates are separated on the end faces of the connecting ends of the two die frames, A baffle plate for the semicircular cavity is formed; a set of tablet pressing components is respectively arranged on the top of each cavity plate. It should be noted that, depending on the specifications of the production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com