Compact waveguide power divider

A compact, power divider technology, used in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of difficult power and phase accuracy, narrow operating bandwidth, guaranteed, etc., to achieve flexible power distribution ratio and phase accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

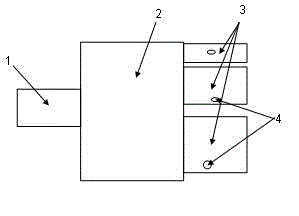

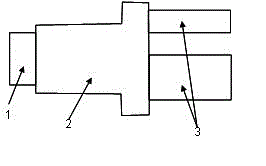

[0027] like figure 2 shown.

[0028] A compact waveguide power splitter, comprising an input end 1, a transition section 2, and at least two output ends 3, the input end 1 is located at the left end of the transition section 2, all output ends 3 are located at the right end of the transition section 2, the input end 1 and the output end 3 are connected with the transition section 2.

[0029] The shape of any cross section of the transition section 2 perpendicular to its centerline or axis from left to right is rectangular.

[0030] The shape of the interface between the input end 1 and the output end 3 at the place connected to the transition section 2 is a rectangle whose height of the transition section 2 is less than 2 / 3 of the depth of the transition section 2, and the output end 3 is at the transition section 2. The right side is arranged in the order of first, second...last from top to bottom, the upper edge of the right end of the transition section 2 is higher than ...

Embodiment 2

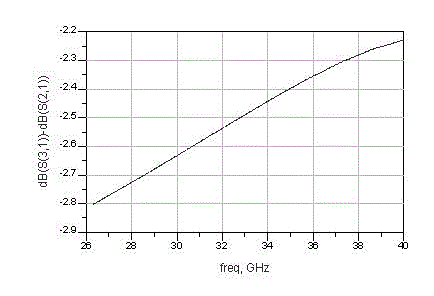

[0046] like Image 6 . The main difference from the implementation example 1 is that the power splitter is a three-way power splitter. The number of the output ends 3 is 3 or more than 3, each of the output ends 3 is provided with a waveguide discontinuity structure, the waveguide discontinuity structure is a waveguide step, a tuning screw, or can cause a reflection coefficient on the waveguide For other protrusions or depressions greater than or equal to -30dB and less than or equal to -15dB, the electrical length between the center of the waveguide discontinuity structure and the right end face of the transition section 2 is greater than 30 degrees or equal to and less than or equal to 60 degrees. The first and third outlets 3 are bent away from the other outlets 3 .

[0047] The above are examples only. In actual production, the number of output terminals can be 2, 3, 4, up to 10 or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com