A high-voltage connector

A high-voltage connector and pivoting technology, which is applied in the direction of connection, parts of the connection device, protective grounding/shielding device of the connection part, etc., can solve the problems of high cable voltage and potential safety hazards, and achieve the effect of good waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

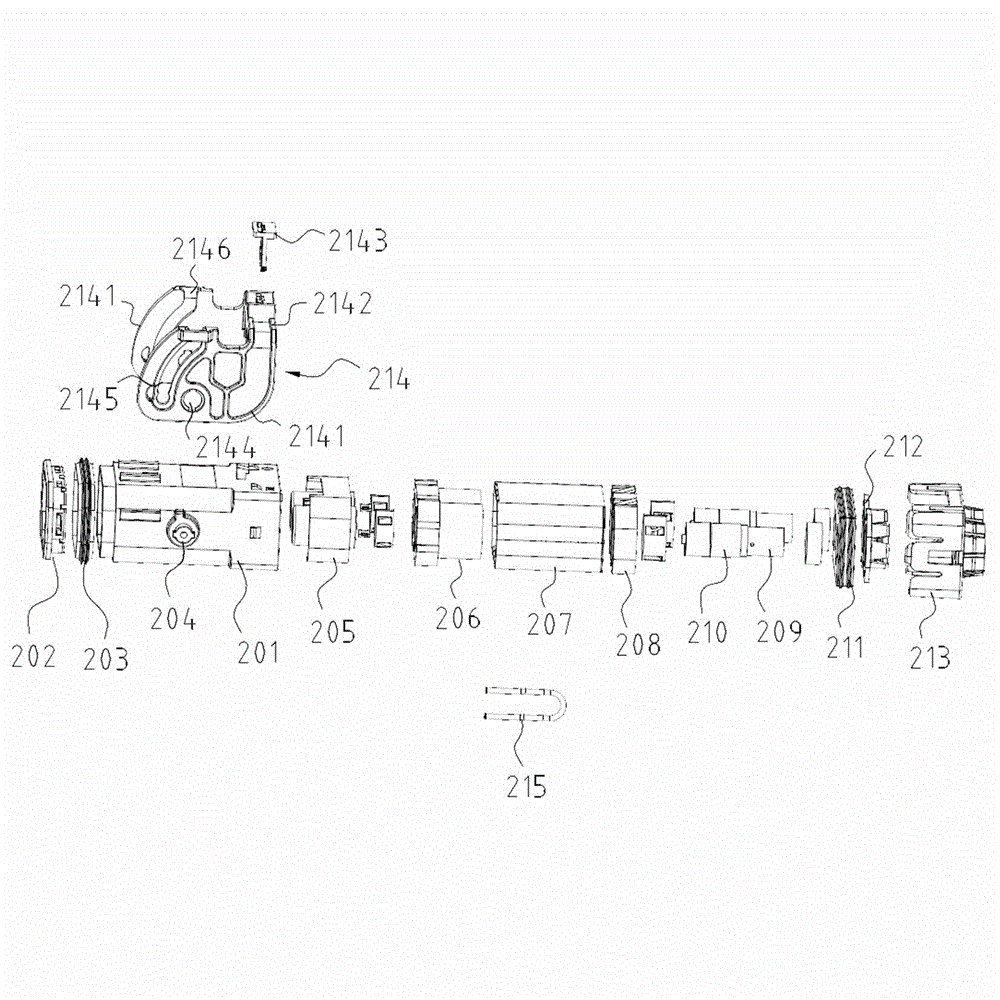

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

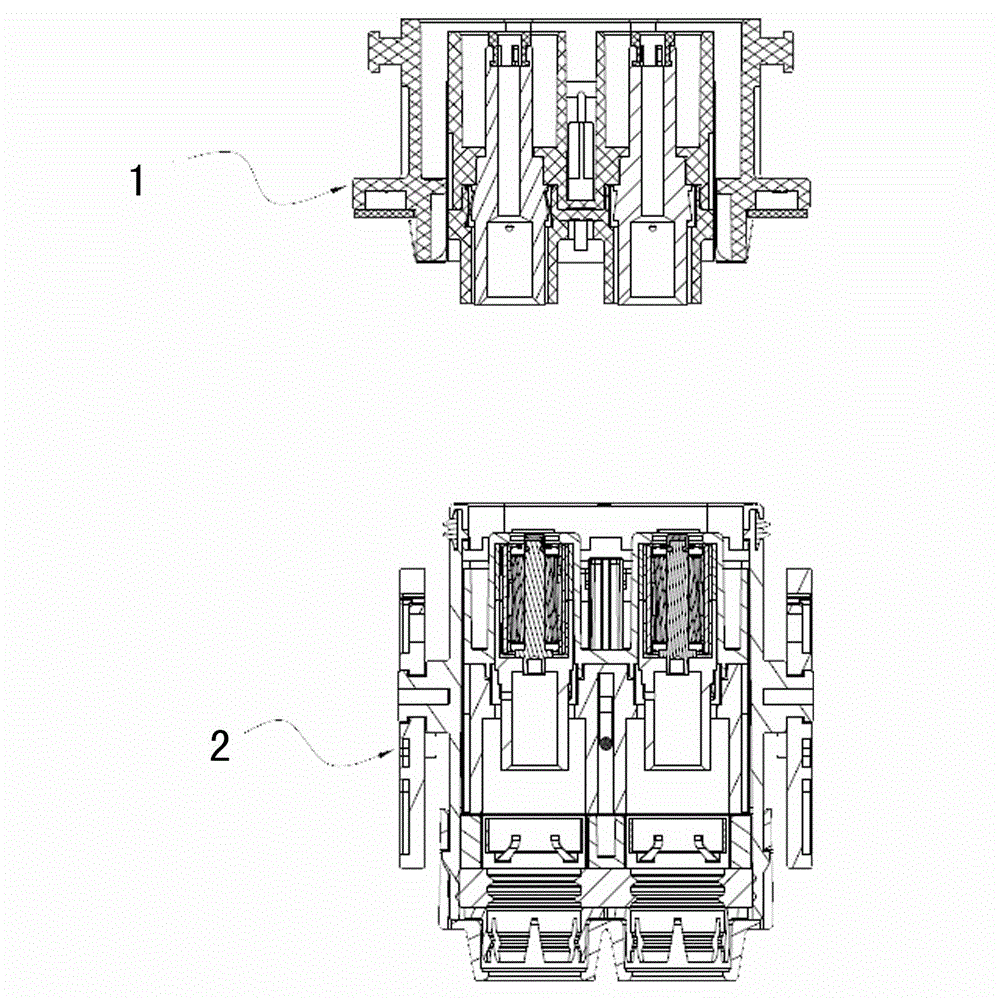

[0025] Such as figure 1 As shown, a high-voltage connector includes a plug 2 and a socket 1. The plug 2 in this embodiment is a straight plug, but the technical solution of the present invention is also applicable to a curved plug.

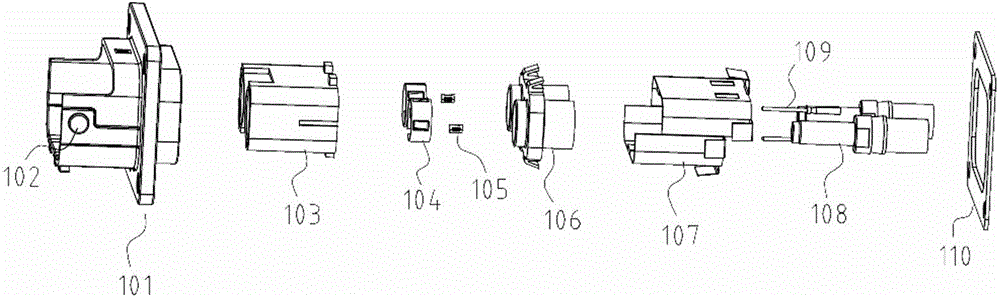

[0026] Such as figure 2 As shown, the socket 1 includes a first plastic shell 101, a first metal shielding shell 107 is arranged inside the first plastic shell 101, and a first front plastic rubber core 103 and a first front plastic rubber core 103 are arranged inside the first metal shielding shell 107. The first rear plastic rubber core 106 . Both the first front plastic rubber core 103 and the first rear plastic rubber core 106 are provided with a first installation hole, and a large current pin 108, a small metal claw 105 and a large metal clamp are arranged in the first installation hole. Claw 104. A waterproof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com