Production process of shoe tongue

A production process and tongue technology, which can be applied to shoe uppers, footwear, boot legs, etc., can solve problems such as poor comfort and high friction, and achieve the effects of improving comfort, buffering friction, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

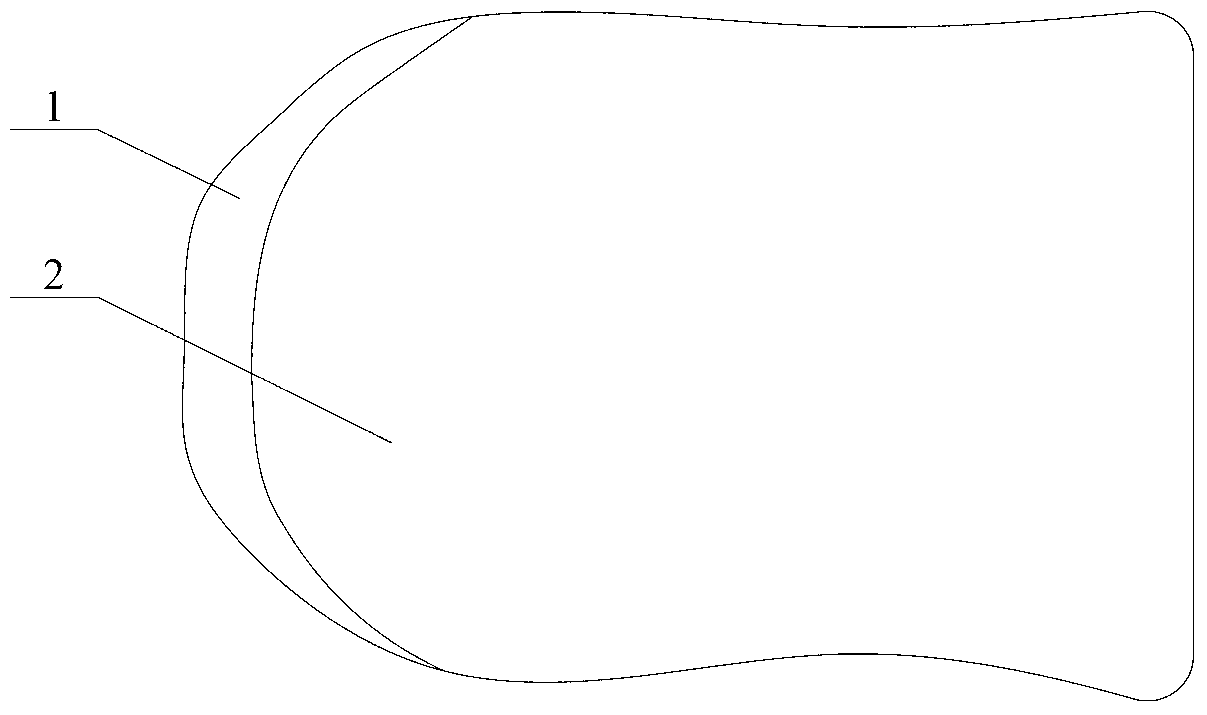

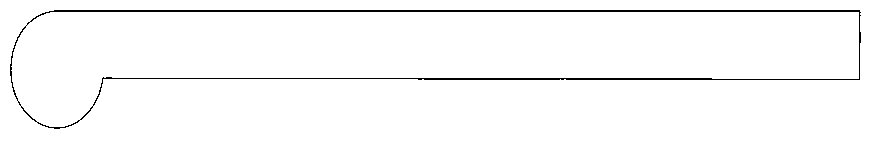

[0025] Such as Figure 1-6 As shown, the invention provides a shoe tongue manufacturing process, comprising the following steps:

[0026] Step A10, making the inner surface of the tongue, the surface of the tongue and the upper end of the foam the same;

[0027] Step A20, the reverse side of the shoe tongue and the upper arc of the shoe tongue surface, stop at a distance of 1 / 2 to 1 / 3 from the two ends;

[0028] Step A30, uniformly spray glue on the upper end of the foam at 30-40 mm;

[0029] Step A40, stick the foam on the reverse side of the tongue surface, and the upper end of the foam protrudes 3-4 mm from the top of the tongue surface, and the fit is firm. In this step, through the structural design of the foam protruding from the tongue surface, Combined with the elastic properties of foam, it can well cushion the friction of the tongue against the instep; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com