Device for removing steel bundling machine bundling wire oxide skin

A technology for descaling and baling, which is applied in chemical instruments and methods, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the problem of high cost and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

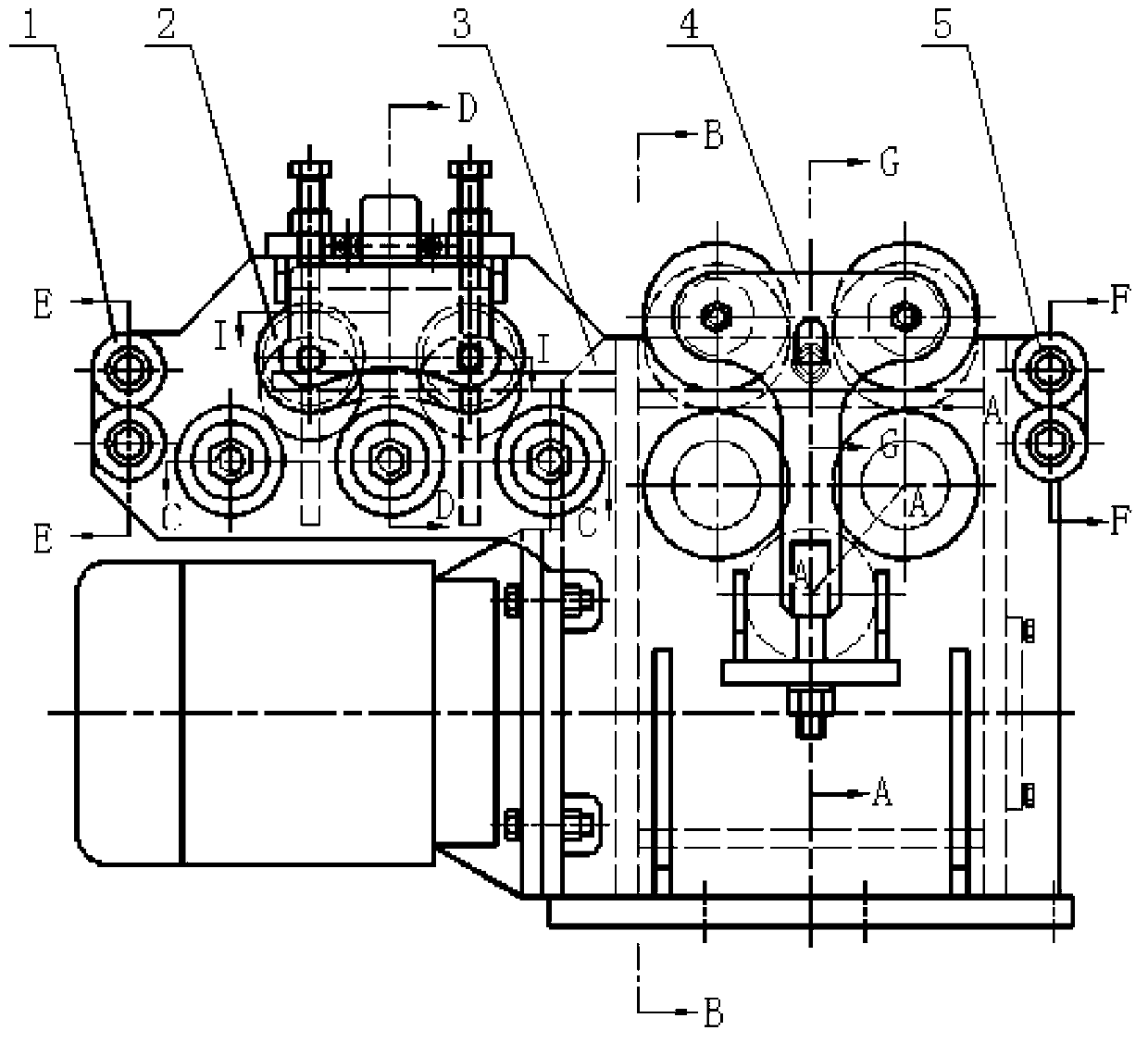

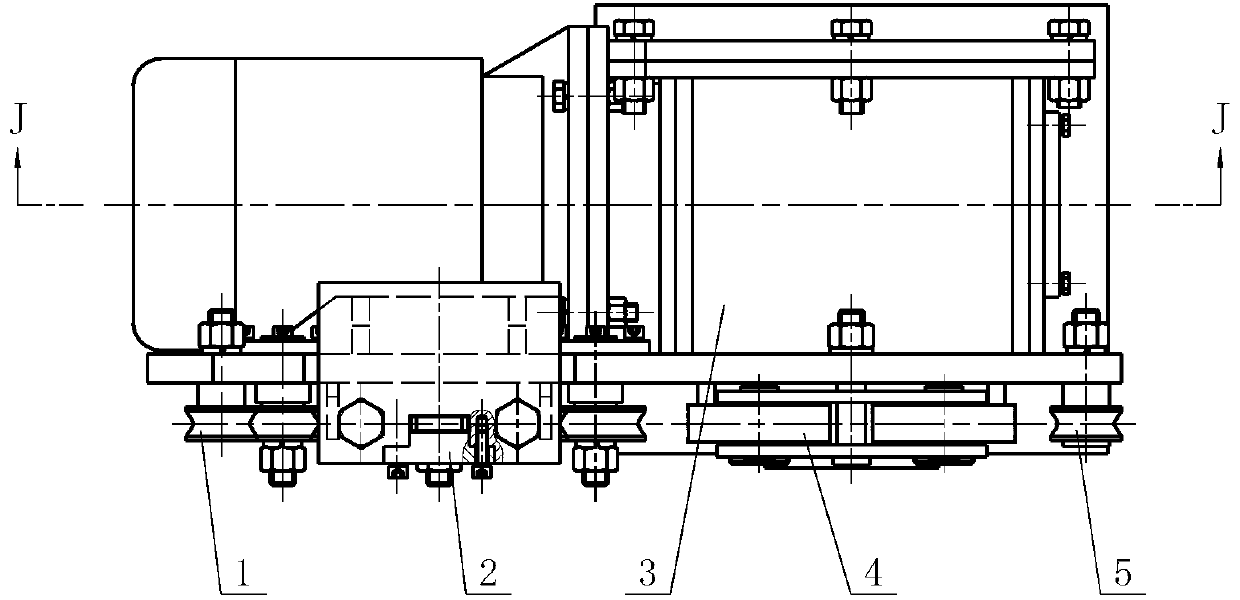

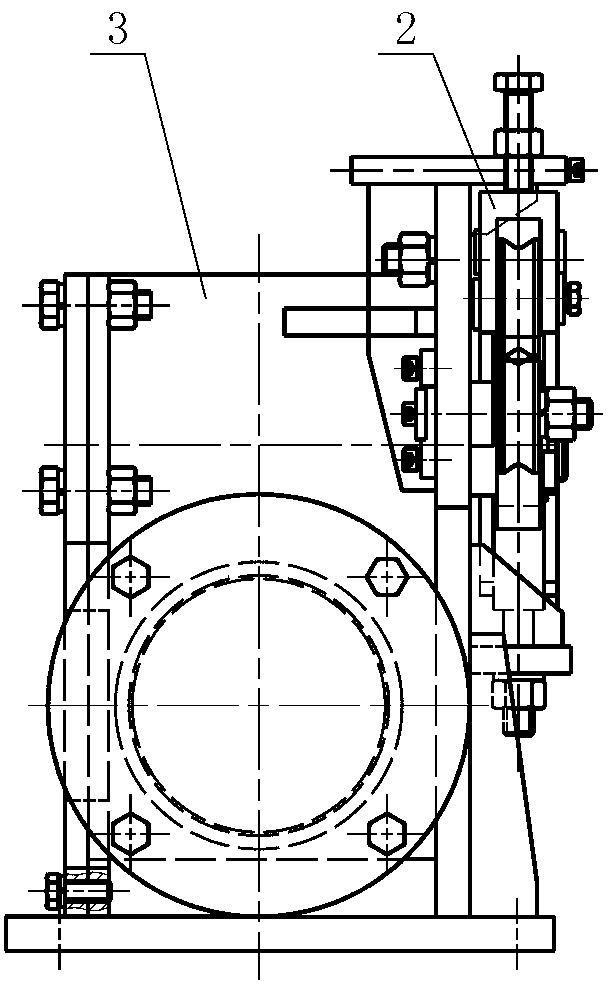

[0020] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings: Figure 1 to Figure 13 The illustrated embodiment is mainly composed of a motor 39 connected to each other, a wire feeding guide wheel group 1, a deoxidized skin wheel group 2, a gearbox 3, a wire binding pressing device 4, and a wire outlet guiding wheel group 5; Group 1 is installed on the vertical plate 29 of the upper left part of the gearbox 4 through the bolt shaft b28; the descaling wheel group 2 is composed of the descaling fixed wheel 24 and the descaling wheel installed on the compression adjustment block 26 through the bolt shaft d34 The fixed wheel 24 is axially positioned on the shaft sleeve b22 through the bolt shaft a21, the shaft sleeve b22 is installed on the vertical plate 29 of the gearbox 4 through the bolt a23, and the upper part of the compression adjustment block 26 is located on the vertical plate 29 In the groove of top horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com