Method for machining submerged pump impeller

A processing method and submerged pump technology, which are applied in the processing field of industrial pump impellers, can solve problems such as low processing accuracy, low production efficiency, and difficulty in ensuring the accuracy of size, shape, and position tolerances, and achieve improved production efficiency, convenient processing, and guaranteed The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

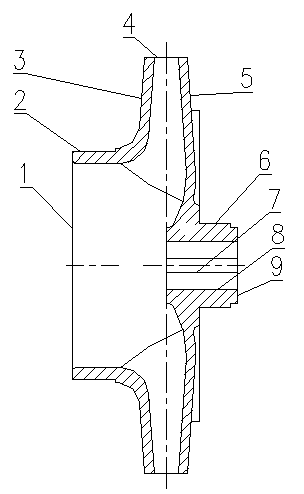

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] Referring to the accompanying drawings, a method for processing an impeller of a submerged pump is characterized in that it includes the following steps: 1) Three-jaw chuck clamps four large outer circles of the impeller, roughing the impeller mouth ring 2, plane A1 and front Cover plate 3; 2), surface adjustment, three-jaw chuck clamping ring, corrected roughing plane B9, drilling 8, roughing rear cover plate 5 and sealing surface 6, roughing large outer circle 4; 3) , Finish turning plane B9, bore 8, finish turning rear cover plate 5 and sealing surface 6 meet the requirements of the drawing, and chamfer; 4) Turn the mandrel, insert the impeller into the mandrel and tighten it with nuts, finish turning plane A (1) Control the total length according to the requirements of the drawings, the mouth ring 2 and the front cover plate 3 meet the requirements of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com