Novel rotary feeding device

A rotary feeder, a new type of technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of failure to achieve good results, failure to obtain timely compensation, etc., to reduce the phenomenon of gas ejection and gaps No change, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

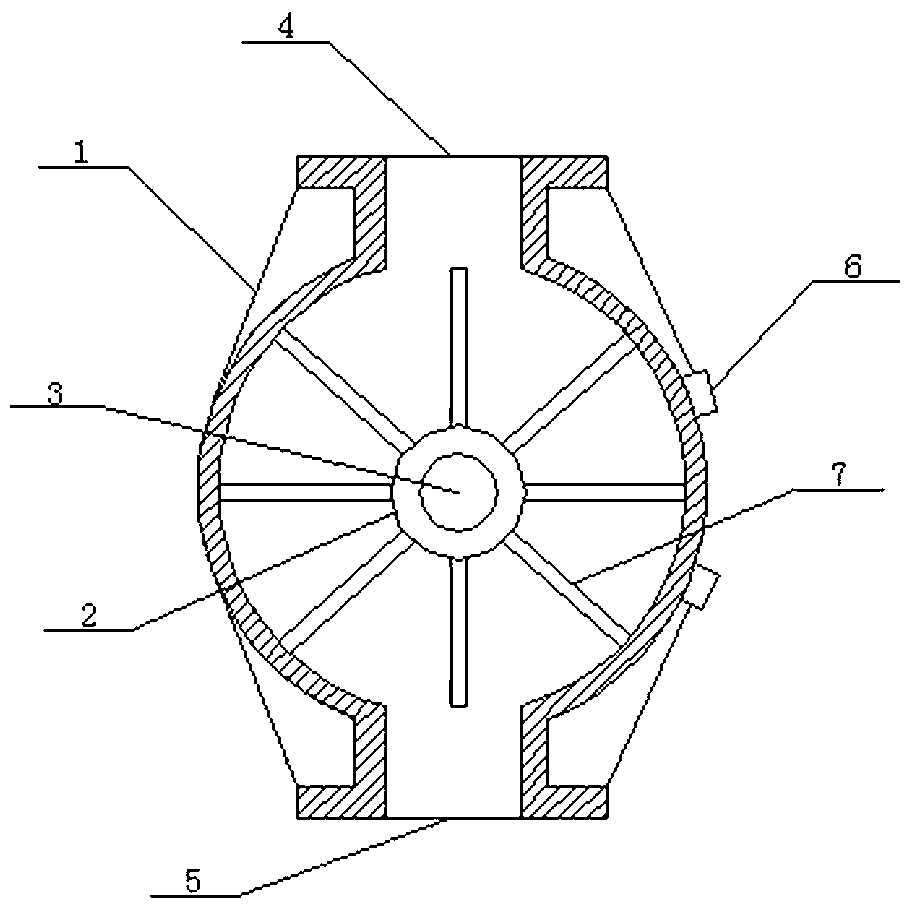

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: a new type of rotary feeder, including a housing 1, a star rotor 2 arranged in the housing 1, the star rotor 2 rotates at a constant speed through a bearing 3, The use of bearings can ensure reliable operation and the gap remains unchanged. The top of the housing 1 is provided with a material inlet 4, the bottom is provided with a material outlet 5, and the side wall of the housing 1 is provided with an equal pressure suction port 6 , the star rotor 2 is provided with compensable movable blades 7, the movable blades 7 are provided with wear-resistant inserts or wear-resistant bushings, and a packing sealing structure is provided on the end face of the feeder, so that Its sealing is reliable.

[0009] The quantity of the movable blades 7 is 8 pieces.

[0010] refer to figure 1 , when this specific embodiment is used, the material falls between the movable blades 7 of the star rotor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com