Horizontal control method and system of winch lifting platform

A lifting platform and level control technology, applied in the direction of lifting frame, lifting device, clockwork mechanism, etc., can solve the problems of low reliability and low work efficiency, and achieve the effect of good reliability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a level control method for a winch lifting platform. The platform is provided with four winches 1, 2, 3, 4 (see Figure 1a ), each winch corresponds to control a leg of the platform. See Figure 1a , the four winches 1, 2, 3, 4 (respectively placed in the four cabins at the top corner of the platform. Refer to figure 1 , the method includes:

[0049] Step S11, real-time detection of the actual speed of each winch;

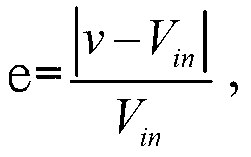

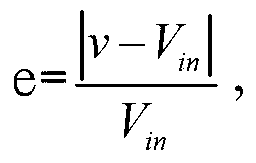

[0050] Step S12, for each winch, when the difference rate between the actual speed and the first given speed is within the allowable range, control the winch to run at the first given speed, wherein the difference rate between the actual speed and the first given speed is The calculation formula is: v is the actual speed, V in is the first given speed, e is the difference rate between the actual speed and the first given speed, end.

[0051] It can be seen from the above technical solution that in this embodiment, during the ...

Embodiment 2

[0057] This embodiment provides another method for controlling the level of the winch lifting platform. The platform is provided with four winches 1, 2, 3, 4 (see Figure 1a ), each winch corresponds to control a leg of the platform. See Figure 1a , the four winches 1, 2, 3, 4 (respectively placed in the four cabins at the top corner of the platform. Refer to figure 2 , the method includes:

[0058] Step S21, real-time detection of the actual speed of each winch;

[0059] Step S22, obtain the inclination angle of the platform, judge whether the inclination angle is 0, if yes, continue to step S23, if not, go to step S24;

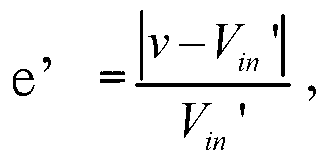

[0060] Step S23, for each winch, when the difference ratio between the actual speed and the first given speed is within the allowable range, control the winch to run at the first given speed, wherein the difference ratio between the actual speed and the first given speed The formula for calculating is: v is the actual speed, V in is the first given...

Embodiment 3

[0065] This embodiment provides yet another method for controlling the level of the winch lifting platform. The platform is provided with four winches 1, 2, 3, 4 (see Figure 1a ), each winch corresponds to control a leg of the platform. See Figure 1a , the four winches 1, 2, 3, 4 (respectively placed in the four cabins at the top corner of the platform. Refer to image 3 , the method includes:

[0066] Step S31, real-time detection of the actual speed of each winch;

[0067] Step S32, obtain the inclination angle of the platform, judge whether the inclination angle is 0, if yes, continue to step S33, if not, go to step S34;

[0068] Step S33, for each winch, when the difference ratio between the actual speed and the first given speed is within the allowable range, control the winch to run at the first given speed, and end;

[0069] Step S34, according to the inclination angle of the platform, determine the winches that need to be corrected for a given speed and the winc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com