High efficiency heating device

A heating device, high-efficiency technology, applied in lighting and heating equipment, heat exchange equipment, heat exchanger types, etc., can solve problems such as high operating temperature of radiators, achieve high-level efficiency, increase overall efficiency, and increase power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

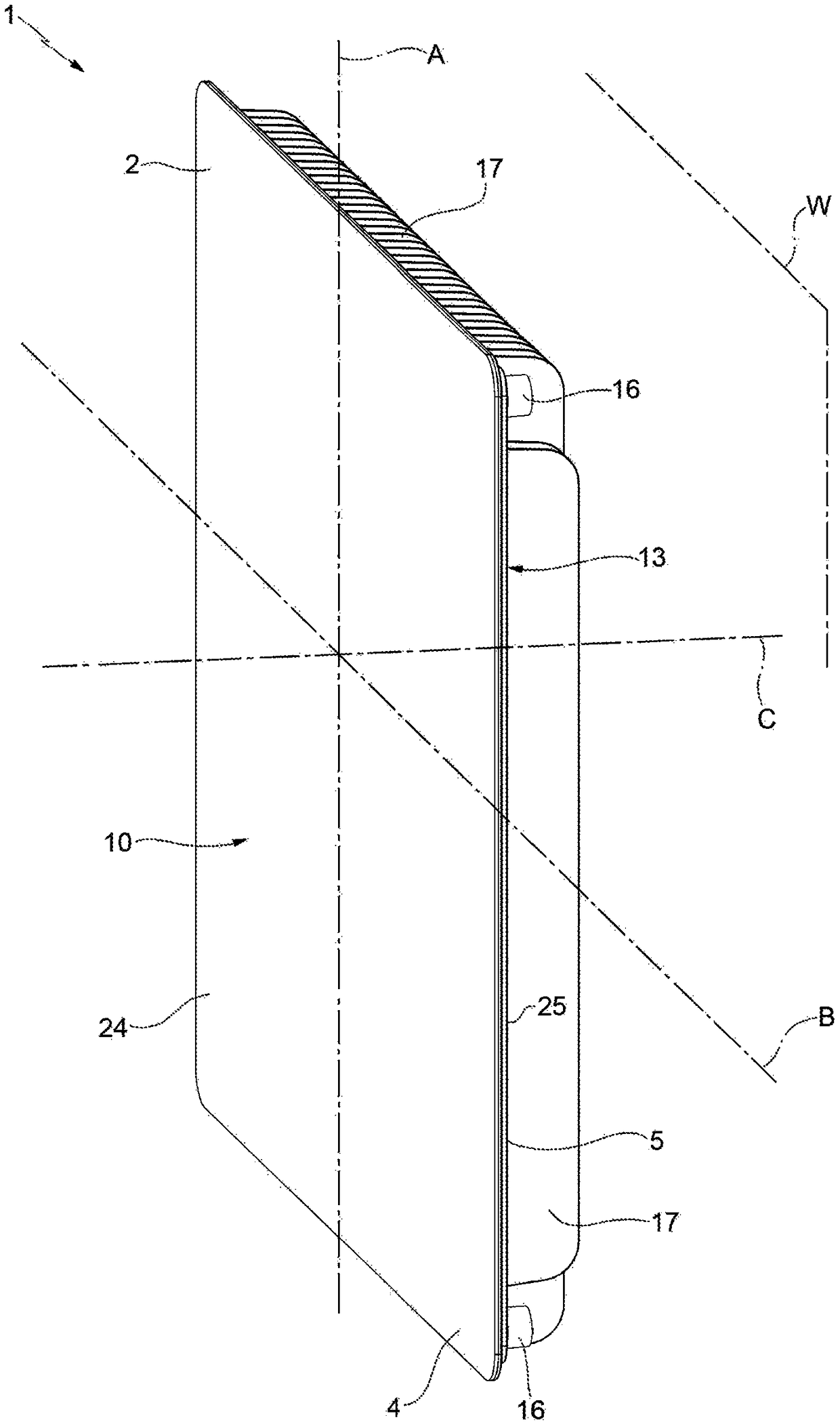

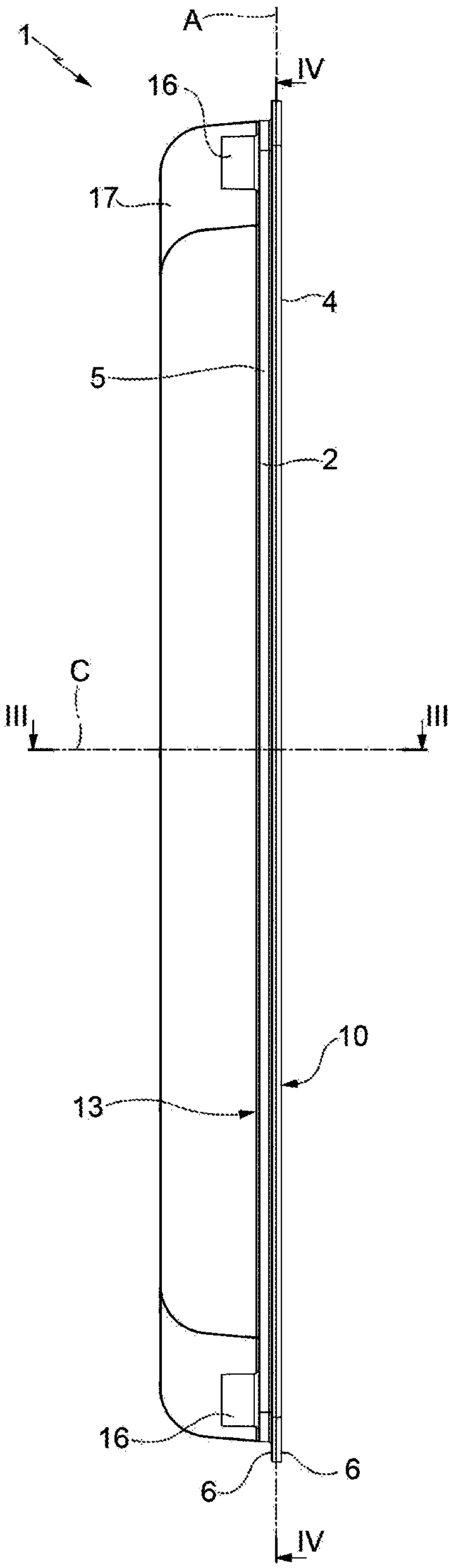

[0026] exist figure 1 and figure 2 In , a heating device of the hydronic (for example, hot water) type (for heating environments in buildings) is indicated as a whole by the reference numeral 1 .

[0027] The device 1 comprises a material made of thermally conductive material, such as (but not necessarily) a metallic material, in particular aluminum (the term also includes aluminum alloys, i.e. alloys containing aluminium) and aluminum obtained, for example, by die-casting (i.e. made of aluminum or The main body 2 is made of aluminum containing aluminum alloy produced by a die-casting process. It should be understood that the body 2 may be made of another material, provided it is suitable for conducting heat, such as ceramics, polymers, composites and others, and produced by other production processes, for example by extrusion.

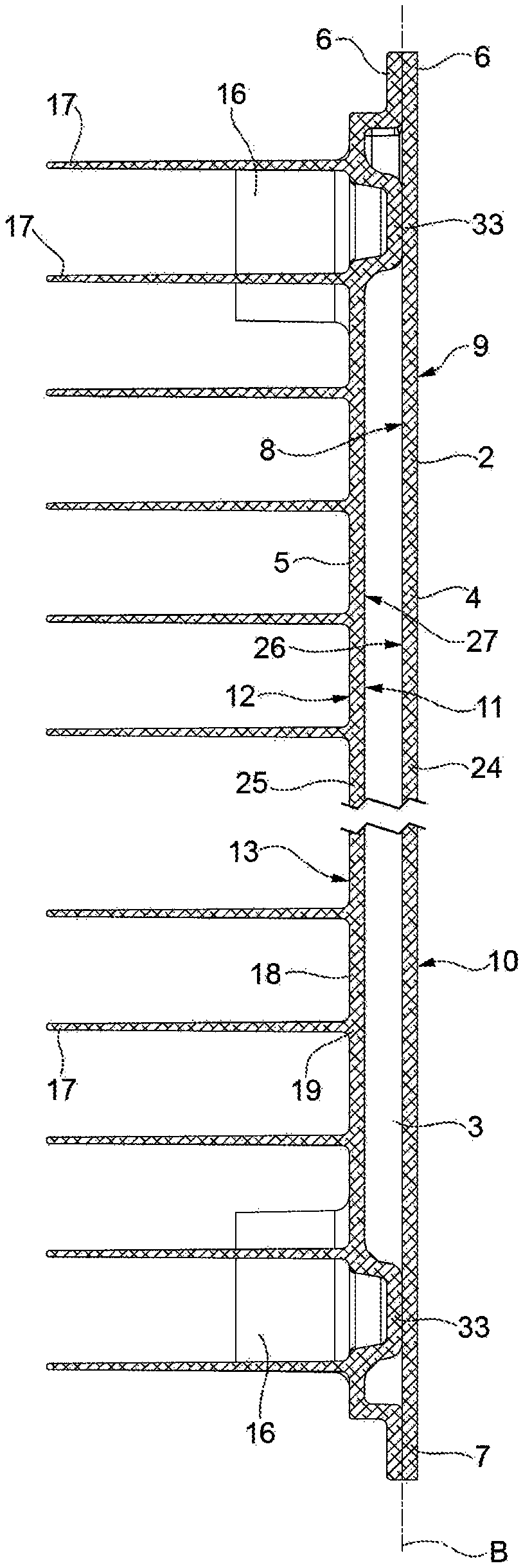

[0028] Also refer to image 3 and Figure 4 , the body 2 is a hollow body and is provided with an inner cavity 3 (water cavity) in which a heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com