Method for constructing anti-typhoon greenhouse

A construction method and anti-typhoon technology, applied in the construction field of crop greenhouses, can solve problems such as insufficient fixing methods, achieve excellent economic efficiency and promotion prospects, good flexibility and operability, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

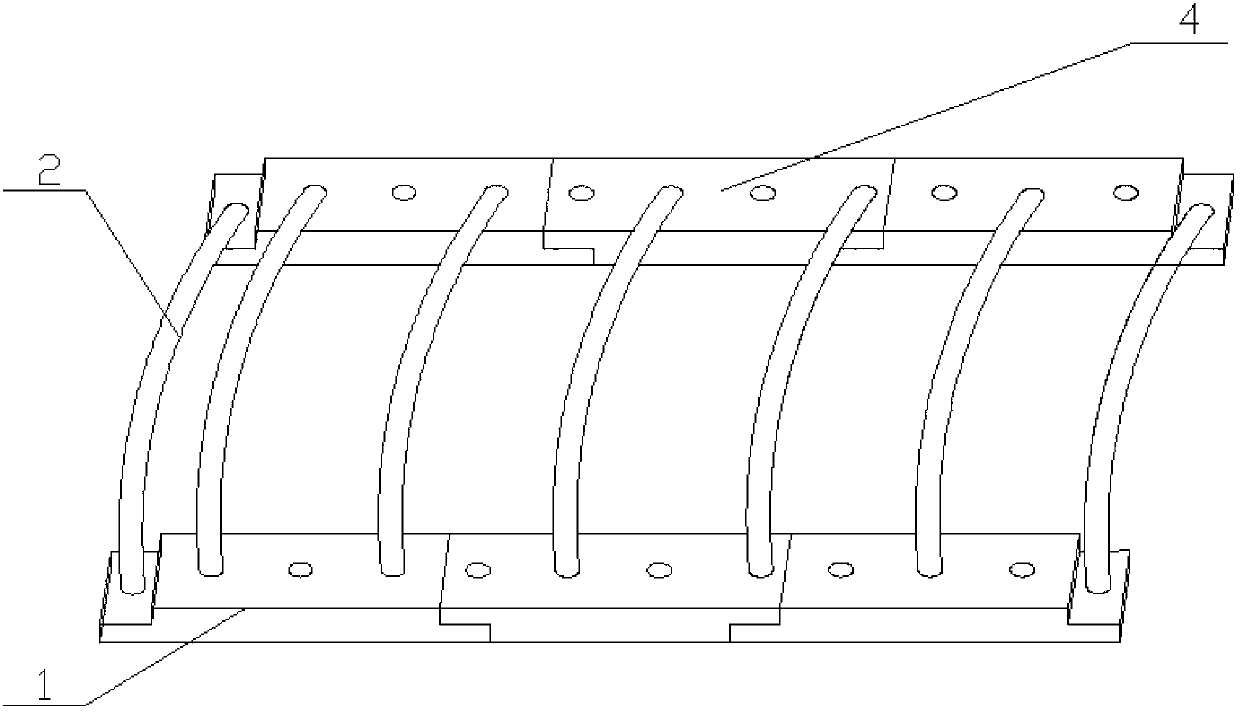

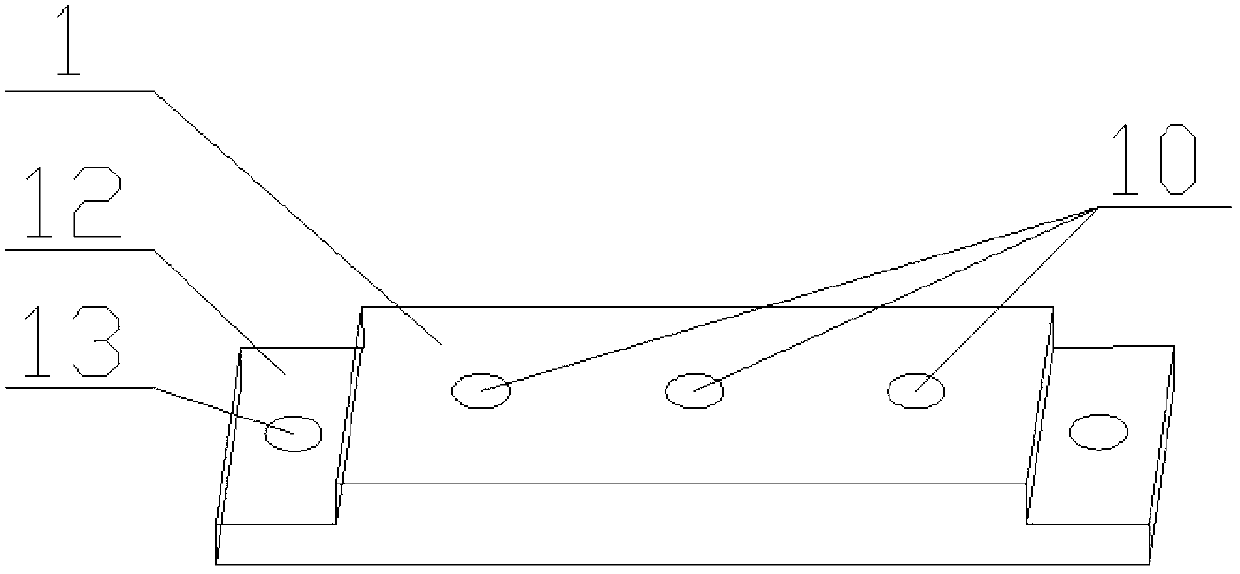

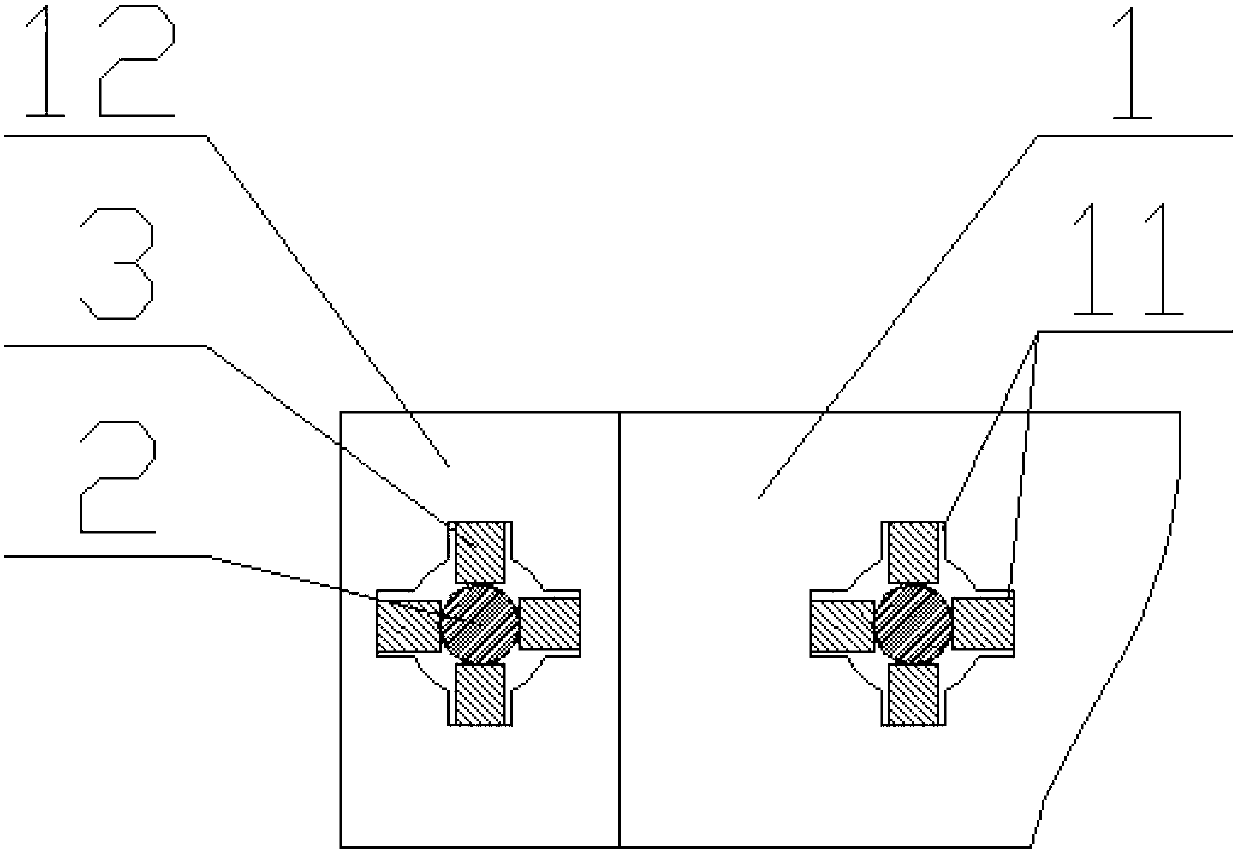

[0019] Such as figure 1 , figure 2 , image 3 As shown, the base 4 of the anti-typhoon greenhouse of the present embodiment includes a cement prefabricated slab 1, the cement prefabricated slab is elongated, and is provided with several equally spaced reserved holes 10 in the length direction, and the two ends of the cement prefabricated slab 1 are provided with There is a stepped protruding part 12, and a connecting hole 13 is opened on the protruding part 12, and the distance between the reserved hole 10 and the connecting hole 13 is generally controlled at 50CM-100CM. The diameter of the reserved hole 10 is the same as that of the connecting hole 13, and runs through the prefabricated cement slab 1, and there are symmetrical gaps 11 around the hole. After the middle, the wedge 3 is inserted into the notch 11 together to provide greater extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com