Testing system and testing method for characteristics of plunger pump

A technology of characteristic testing and testing system, applied in pump testing, liquid variable capacity machinery, machine/engine, etc., can solve problems such as poor reliability and large workload, and achieve the effect of reducing testing cost and improving testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

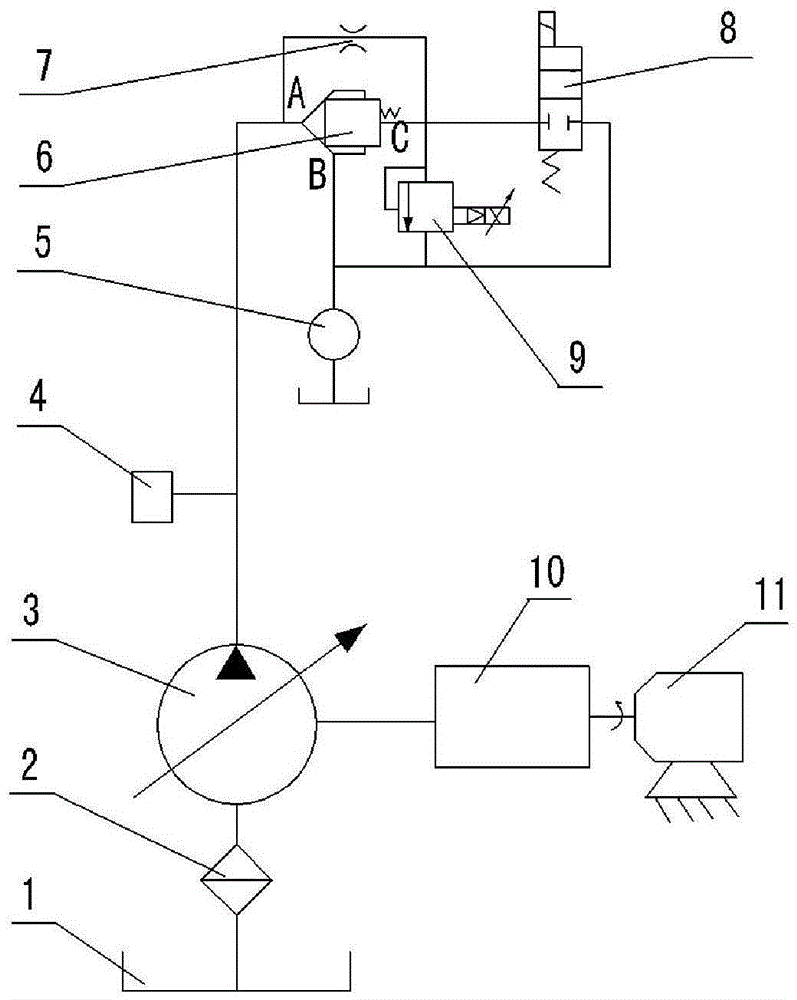

[0031] see figure 1 , the plunger pump characteristic testing system in this embodiment is set as:

[0032] A torque speed tester 10 is set on the output shaft of the drive motor 11 for detecting the input torque and angular velocity of the plunger pump 3;

[0033] A two-way cartridge valve 6 is arranged in the outlet pipeline of the plunger pump 3, and a pressure sensor 4 is arranged on the connecting pipeline between the oil inlet A of the two-way cartridge valve 6 and the outlet end of the plunger pump 3 for detecting the For the output pressure of the plunger pump 3, a flow sensor 5 is installed at the oil outlet B of the two-way cartridge valve 6 to detect the output flow of the plunger pump 3; An orifice 7 is set in the connecting pipeline between the oil inlet A of the valve 6; a pilot proportional relief is arranged in parallel between the control port C of the two-way cartridge valve 6 and the oil inlet of the flow sensor 5 Valve 9 and normally closed two-position t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com