Simplified algorithm of synchronous frequency conversion soft starting motor rotor position detection

A motor rotor and synchronous frequency conversion technology, which is applied in the field of electrical engineering and electronics, can solve the problems that the requirements cannot be met, and the integral algorithm cannot track the rotor position of the rotating motor in time, so as to simplify installation and commissioning, reduce the failure rate and maintenance cost, and design requirements Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] A simplified algorithm for detecting the rotor position of a synchronous variable frequency soft starter motor according to the present invention comprises the following steps:

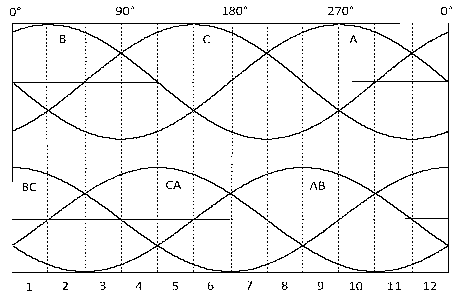

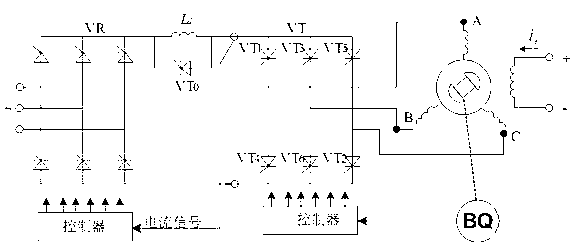

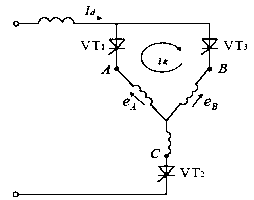

[0030] ①The three-phase voltage waveforms of the synchronous motor stator at different speeds are collected through the voltage Hall and the analog sampling circuit, and are input to the AD sampling port, and the three-way voltage sampling signals are processed by the control DSP;

[0031] In this step, after the motor is started, the voltage at the motor terminal is sensed by the voltage hall to the secondary side to become a low-voltage signal, and then the voltage level is adjusted to a suitable amplitude through the analog sampling circuit, and then input to the AD sampling port, controlled by the DSP processes the three-way voltage sampling signals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com