Supplied film packaging mechanism and object supplied film packaging method

A packaging method and packaging film technology, which are applied in the directions of packaging/bundling items, packaging material feeding devices, packaging, etc., can solve the problems of high technical requirements for design and manufacturing processes, complex structure of film supply packaging mechanisms, and large external dimensions of packaging wheels 5, etc. problem, to achieve the effect of low noise, simple structure, easy installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

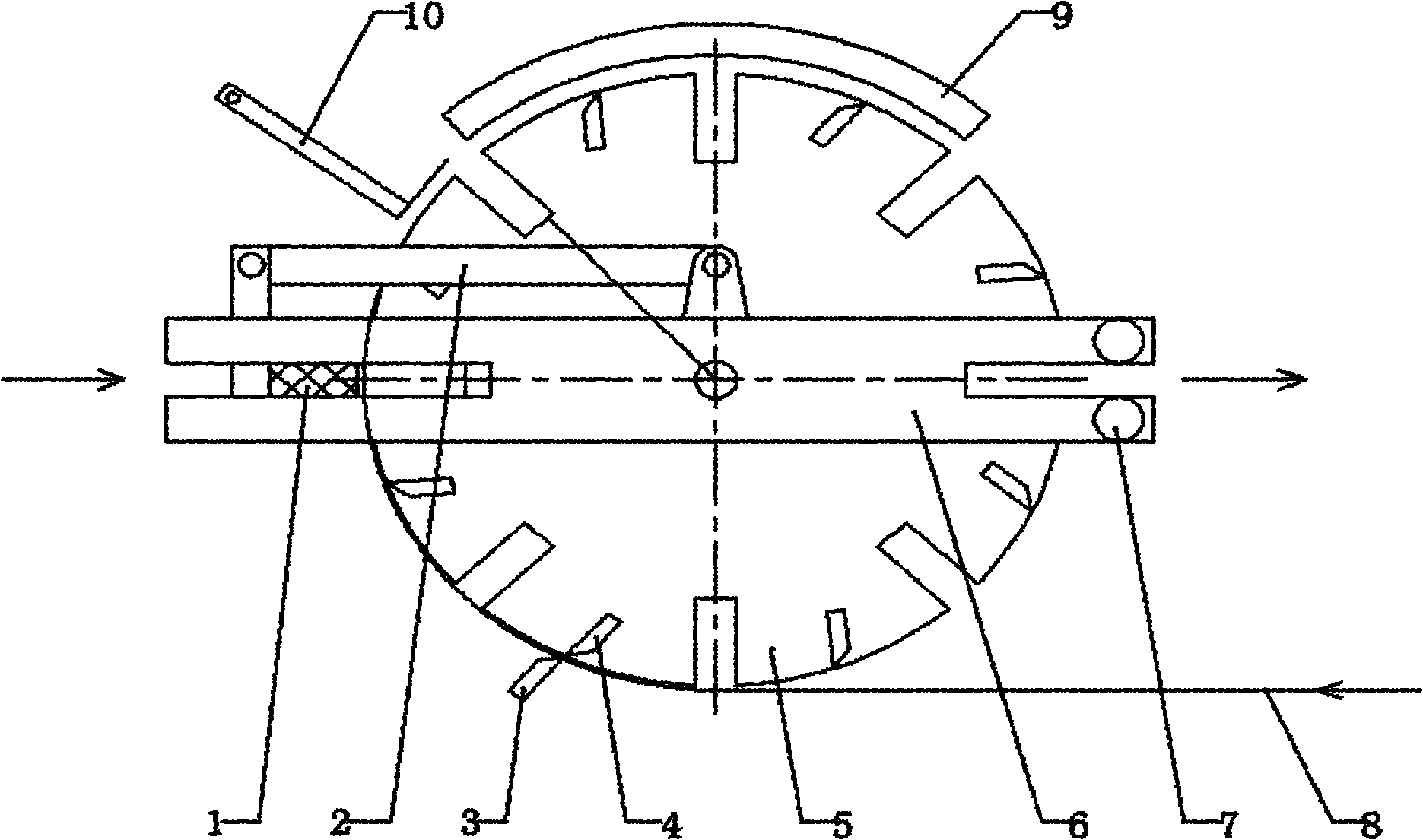

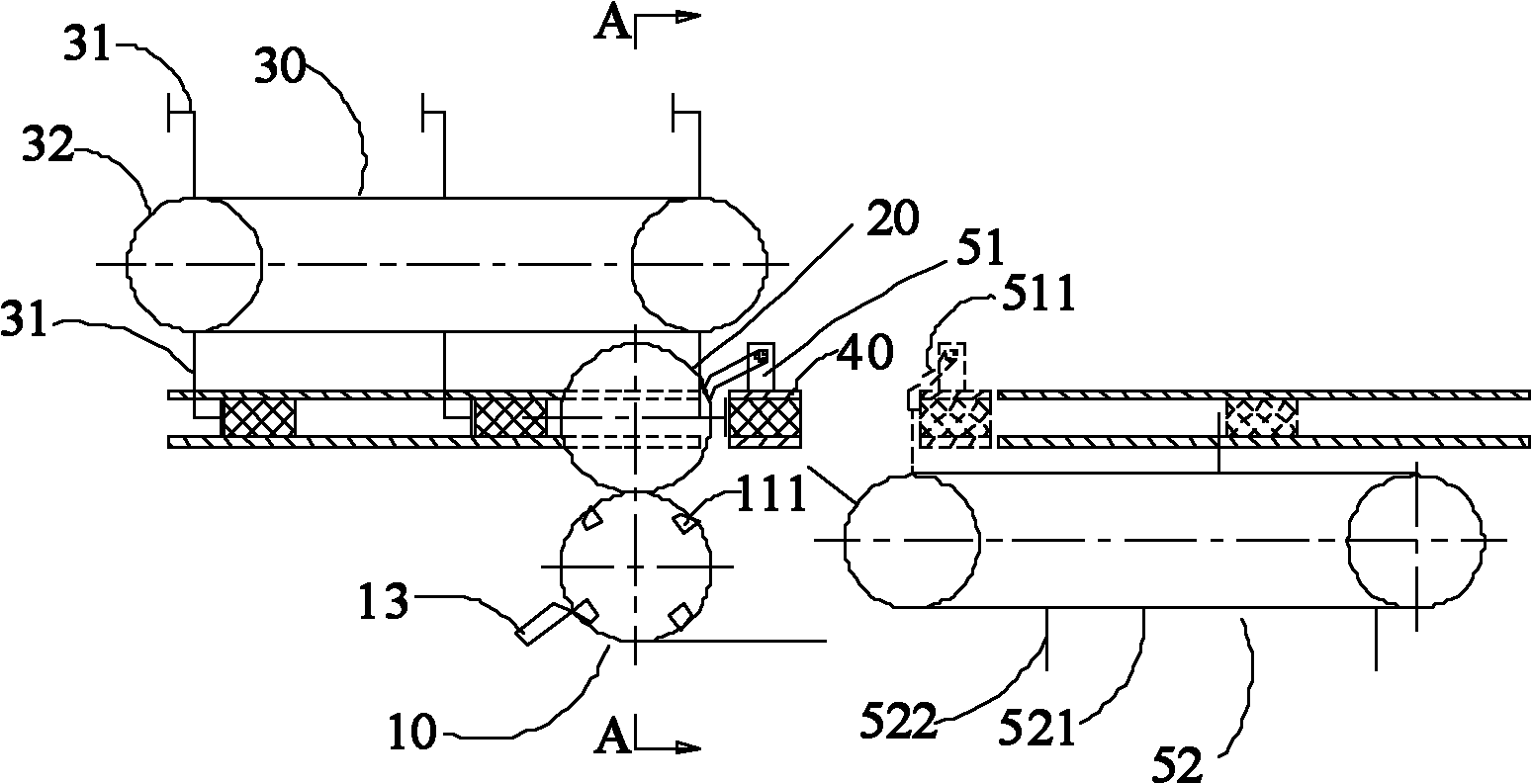

[0038] figure 2 with image 3 Shows the structure of the film feeding and packaging mechanism in one embodiment of the present invention, the film feeding and packaging mechanism includes a cutting device 10, a conveying device 20 and a control device, wherein,

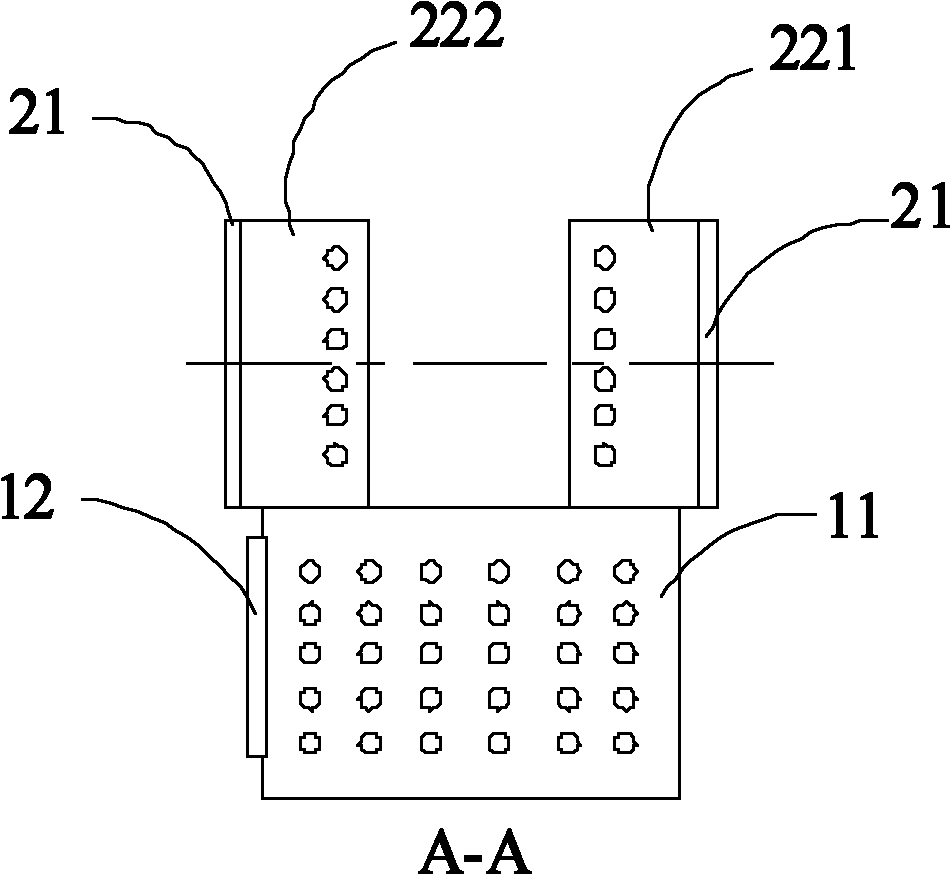

[0039] The cutting device 10 includes a first negative pressure gas distribution plate 11 and a rotatable cutter roller 12 . The cutter roller 12 is provided with a plurality of cutters 112 arranged at preset length intervals and air holes 111 communicated with the first negative pressure gas distribution plate 11 . The cutter 112 is adapted to the bottom knife 13 arranged below the cutter roller 12, and is used to cut off the packaging film tape according to the control of the control device 30 to obtain the packaging film. The air holes 111 provide nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com