CMYK four-color printing chromatic aberration positioning method

A positioning method, four-color printing technology, applied in the direction of image communication, electrical components, etc., can solve the problem of unable to reflect the color difference value of each color plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

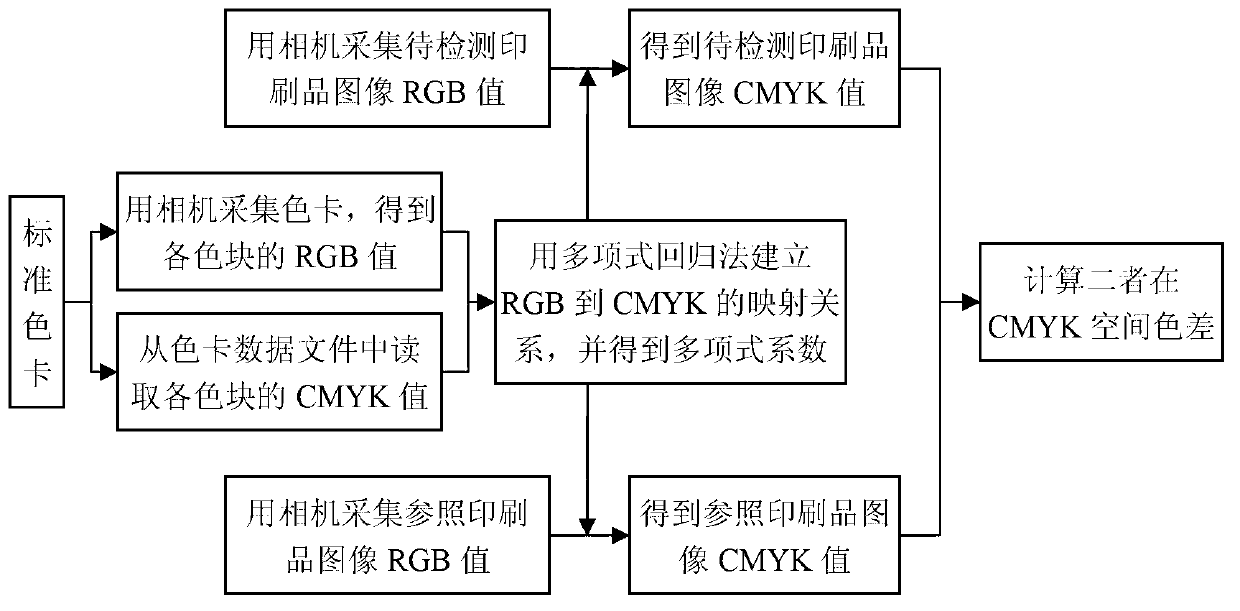

[0039] A CMYK four-color printing color difference positioning method is specifically implemented through the following steps:

[0040] Step 1, use a color camera to capture the IT8Kodak Format standard color card, and read the RGB value of each color block of the color card image;

[0041] Step 2, from the supporting data file of the IT8Kodak Format standard color card in step 1, obtain the CMYK value of each color block on the standard color card;

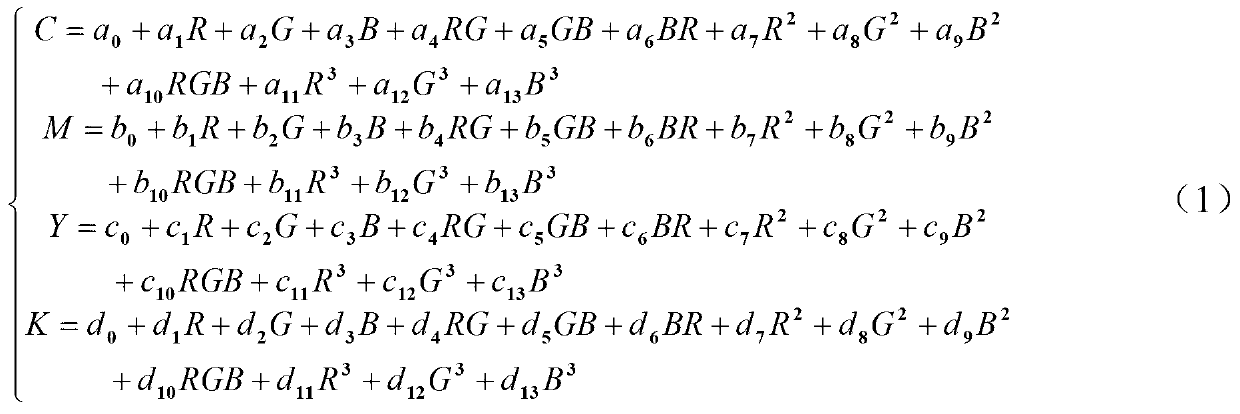

[0042] Step 3: Substituting the RGB values read in step 1 and the CMYK values obtained in step 2 into a 14-term polynomial mathematical model, through the 14-term polynomial regression method, to establish the mapping relationship between RGB values and CMYK values, and then adopt the minimum The polynomial coefficient a is fitted by the square method i , b i 、c i 、d i (i=0,1,...13);

[0043] The mathematical model of the 14-term polynomial is as follows:

[0044] C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com