A carbon fiber heating element for heating clothing and its manufacturing method

A technology of carbon fiber heating and carbon fiber heating wire, which is applied in the field of heating clothing, and can solve the problems of unsatisfactory thermal insulation effect of clothing, unsuitable washing of carbon fiber heating parts, small heating area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

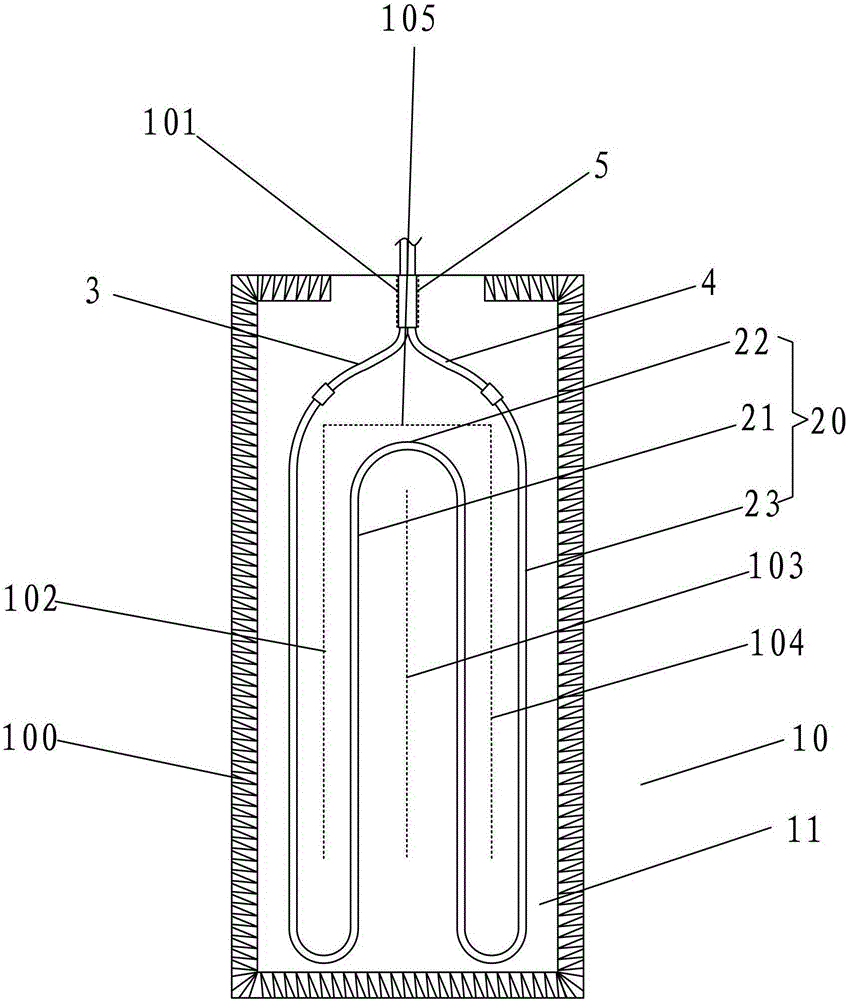

[0031] A carbon fiber heating element for heating clothing of the present invention, such as Figure 1-2 As shown, it includes a cloth block 10 and a carbon fiber heating strip 20 twisted into a strand by several carbon fiber heating wires. The cloth block 10 is a square cloth block, and this square cloth block includes a face cloth block 11 and a bottom cloth block (not shown in the figure Out), the periphery of the surface cloth 11 and the periphery of the bottom cloth 11 are sewn together by sutures 100, an accommodation space is formed between the surface cloth 11 and the bottom cloth, and the carbon fiber heating strip 20 is placed on In the accommodation space, the carbon fiber heating strip 20 includes a first U-shaped part 21, a second U-shaped part 22 and a third U-shaped part 23, and the first U-shaped part 21, the second U-shaped part 22 and the third U-shaped part The parts 23 are all on the same plane, the first U-shaped part 21 is perpendicular to the second U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com