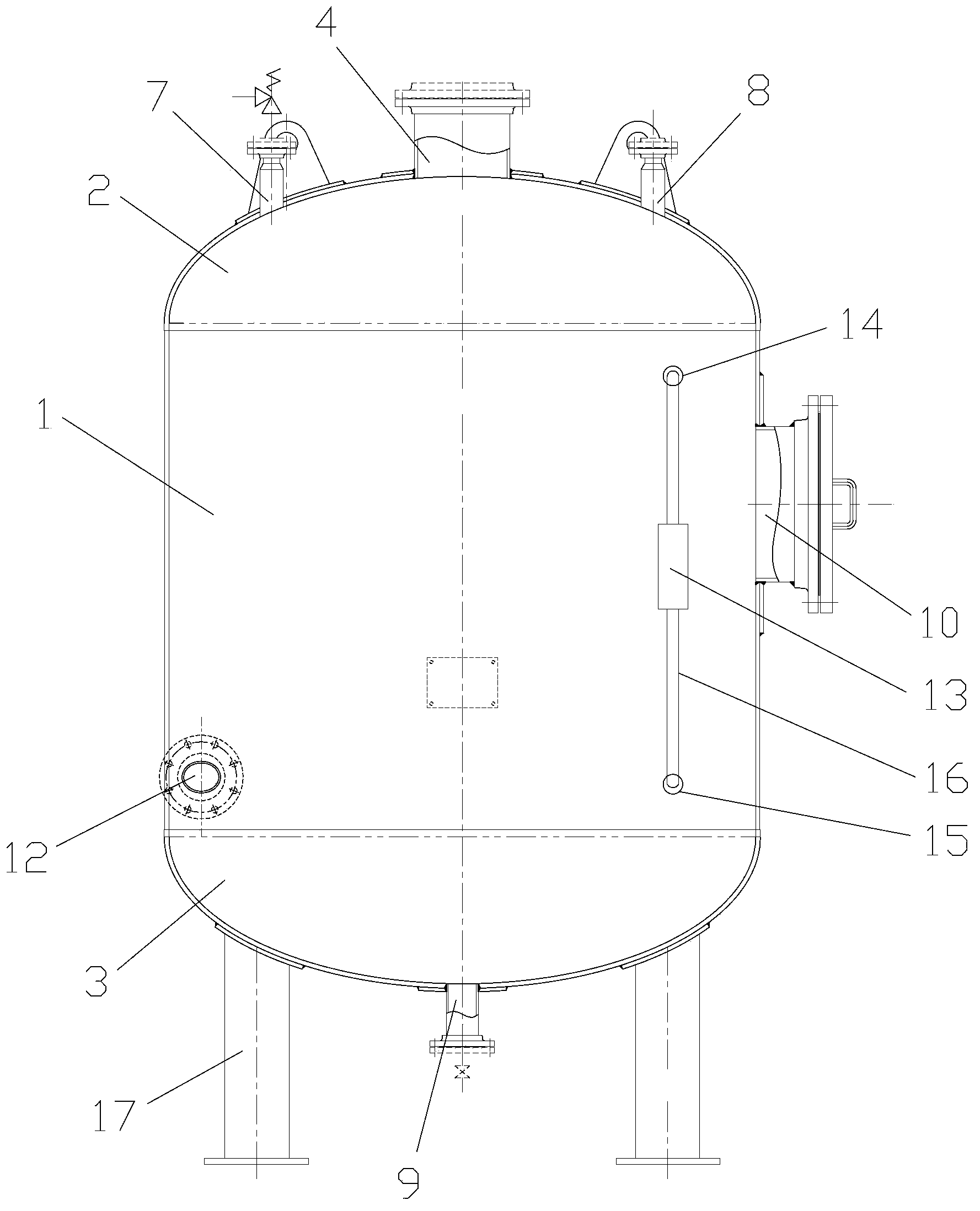

Drain flash tank for heavy oil heater

A technology of hydrophobic expansion vessel and heater, applied in the field of hydrophobic expansion vessel, can solve the problems of inconvenient equipment maintenance and entry and exit of personnel, inaccurate liquid level measurement, poor water flow distribution effect, etc., and achieves good water flow distribution effect and clear display. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

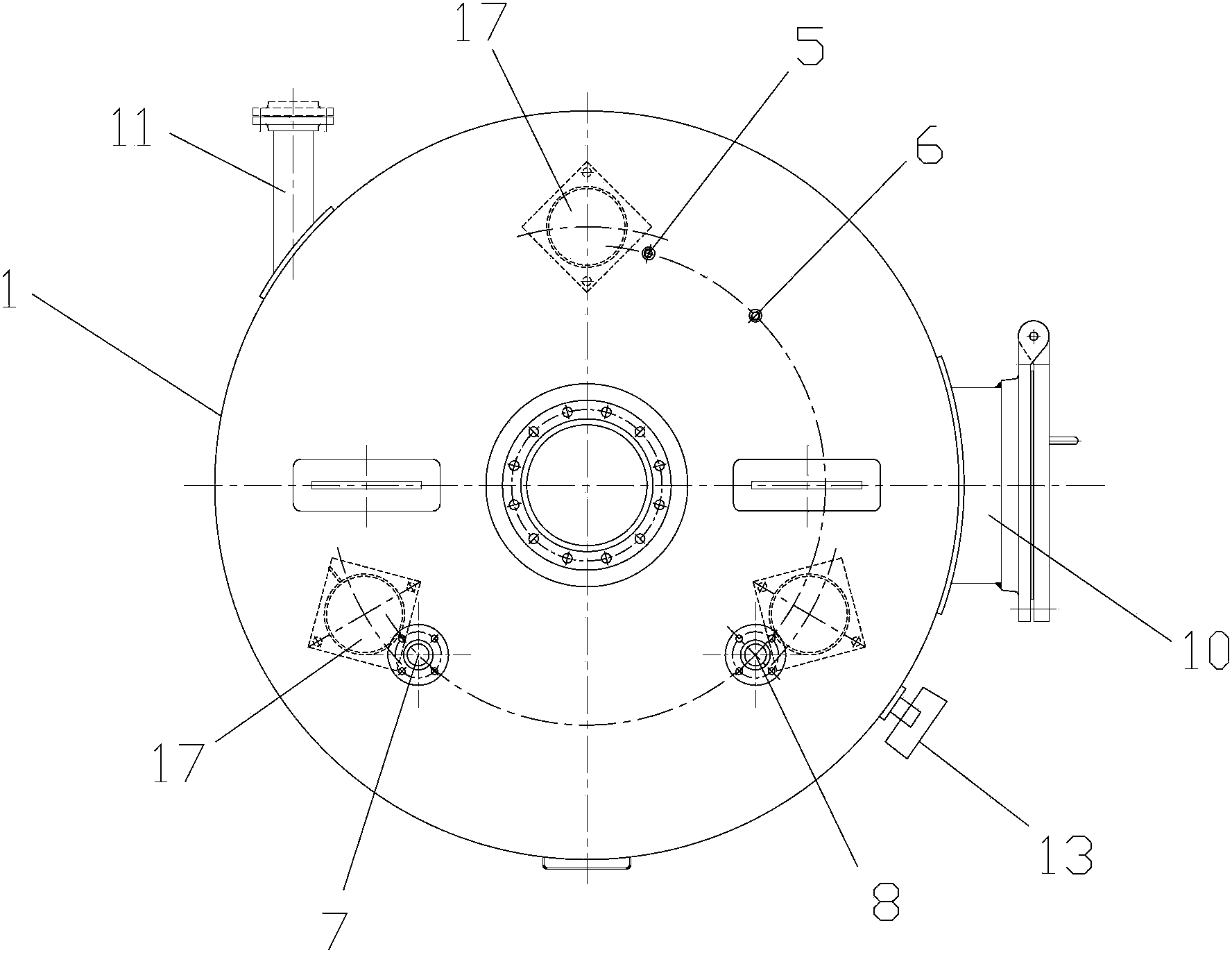

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] see figure 1 and figure 2 , the present invention provides a hydrophobic expander for a heavy oil heater, which includes a vertical cylinder 1, the upper and lower ends of the cylinder 1 are connected with heads 2, 3, and the upper head 2 of the cylinder 1 is provided with There are steam outlet 4, pressure gauge port 5, thermometer port 6, safety valve port 7, spare port 8, and the bottom of the lower head 3 of the cylinder body 1 is provided with a drain outlet 9. A manhole 10 is provided on the side of the cylinder body 1 , and the manhole 10 is located at the upper part of the cylinder body 1 . A hydrophobic inlet 12 with a water inlet pipe 11 is provided at the lower side of the cylinder body 1, and the water inlet pipe 11 communicates with the cylinder body along a tangential direction. The cylinder is also provided with a li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap