Detection apparatus specially used for computer display screen support

A technology for display screen brackets and detection devices, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of bracket scrapping, increasing production costs, wasting production resources, etc., to save costs, prevent batch scrapping, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

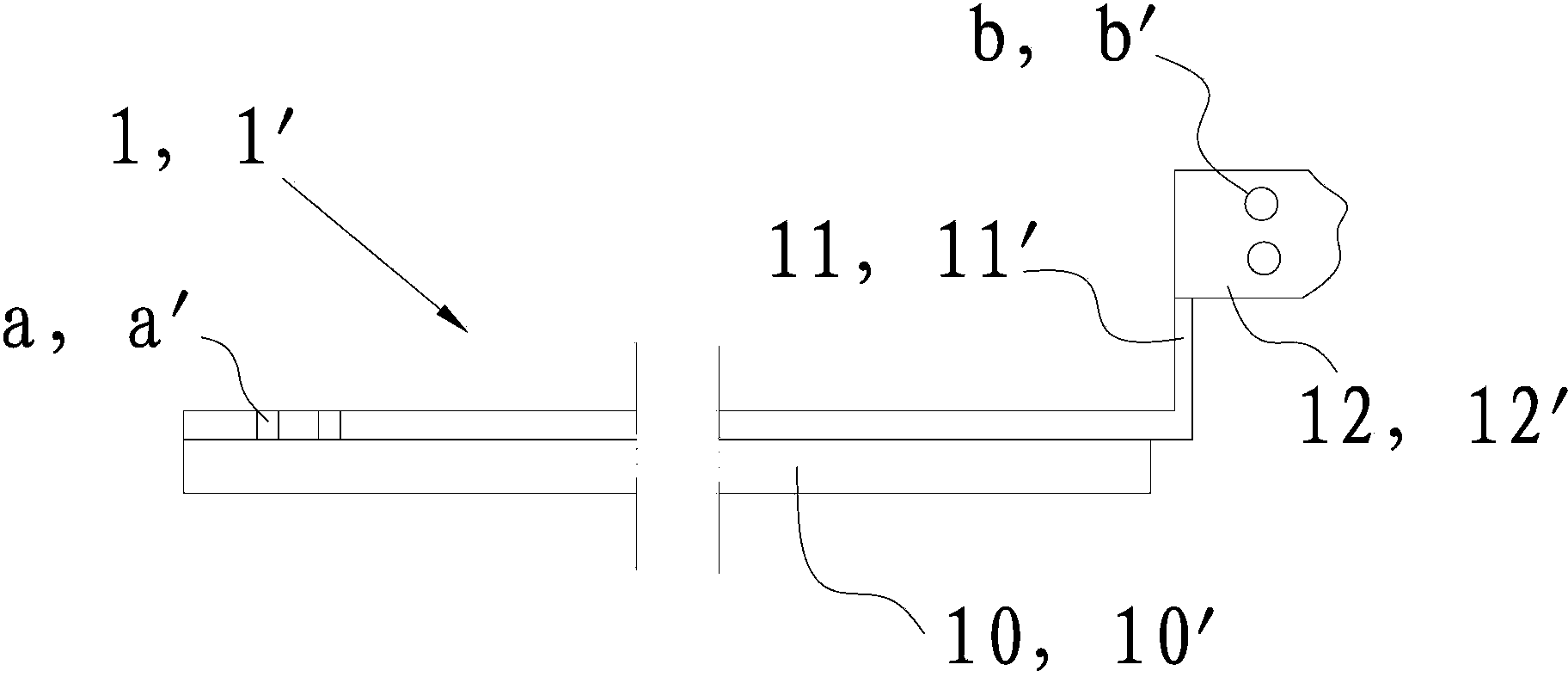

[0022] Such as Figure 1 to Figure 4 As shown, the bracket 1 includes a first shelf plate 10 extending in the horizontal direction and in the shape of an angle iron, and a second shelf bent vertically upward from the edge of any vertical side end of the first shelf plate 10 in the shape of an angle iron. Plate 11, and the third shelf 12 that is arranged on the top of the second shelf 11 and extends horizontally to the right along the thickness direction of the second shelf 11, the width and thickness of the two vertical sides of the first shelf 10 Evenly, a first connection hole a and a second connection hole b are respectively provided on the first shelf board 10 and the third shelf board 12 .

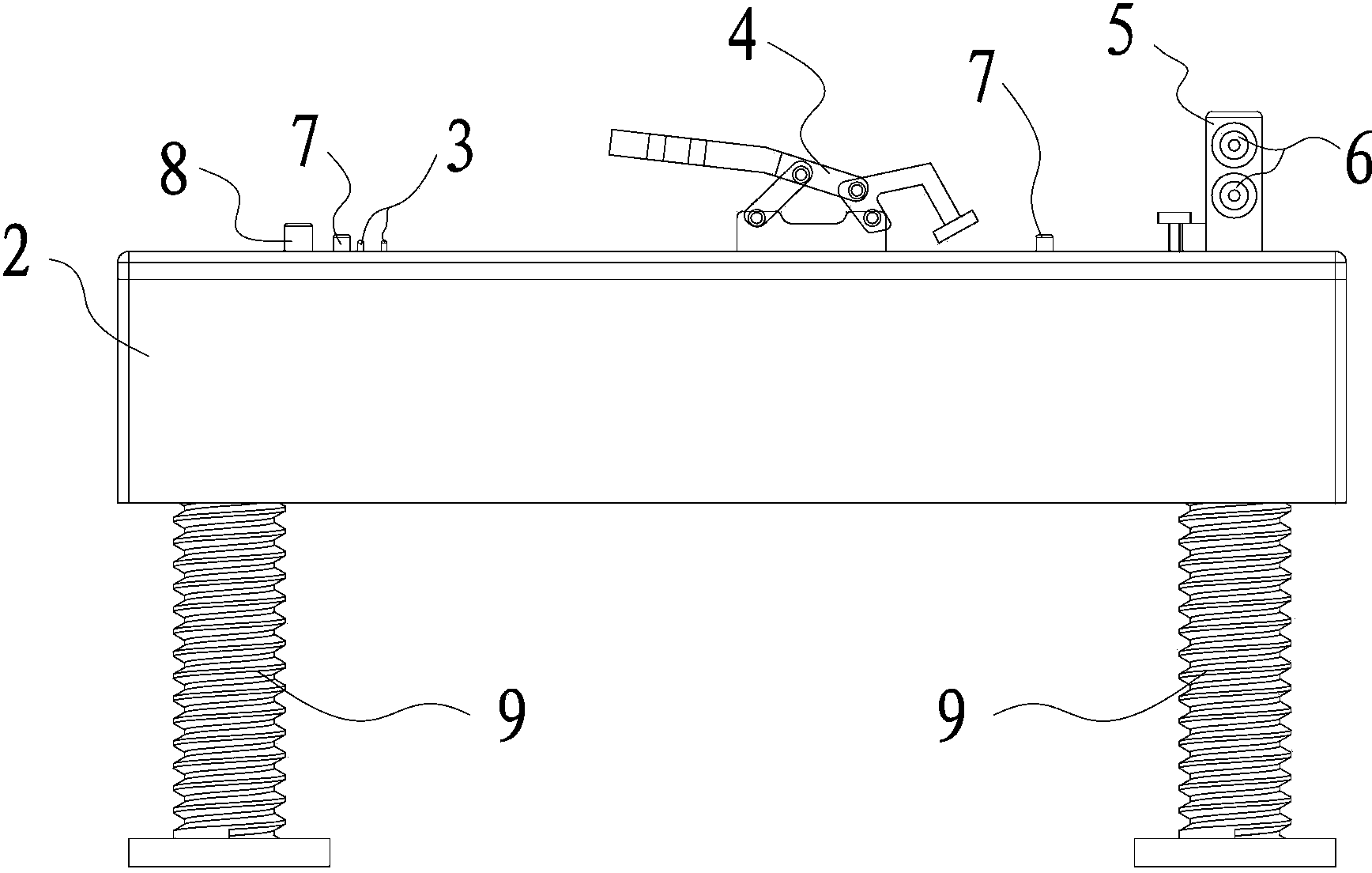

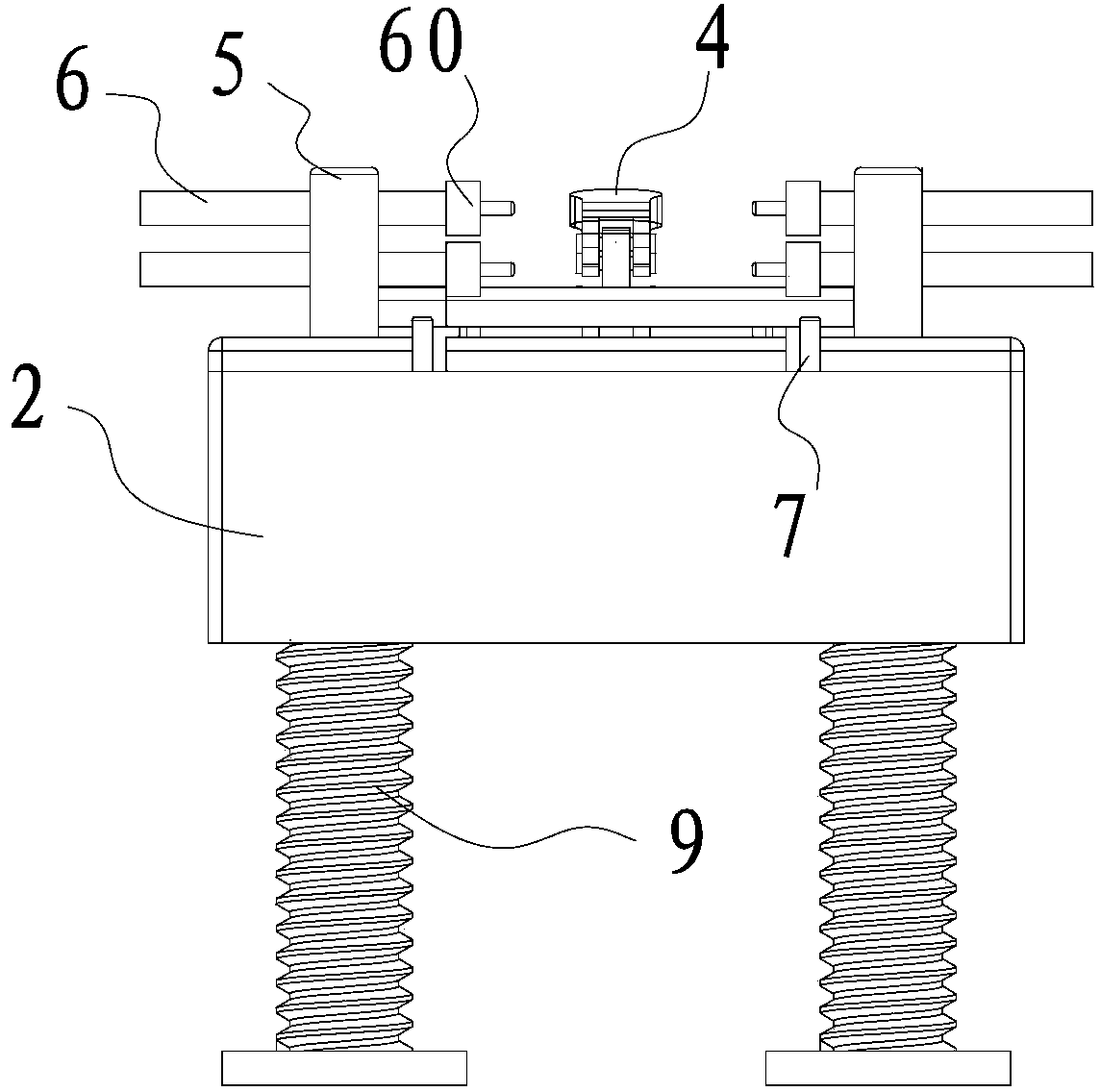

[0023] According to the specific structure of the above-mentioned support 1, the present embodiment provides a detection device dedicated to the support of the computer display screen, which includes a test platform 2 with at least two positioning grooves 20, fixedly arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com