Adaptive STFT based rotary machine order tracking method

A rotating machinery and order tracking technology, which is applied in the field of STFT order tracking, can solve the problems of time-frequency domain aliasing and the limitation of time-frequency resolution that cannot be changed, and achieve the effect of avoiding aliasing and overcoming the fixed window length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific application examples.

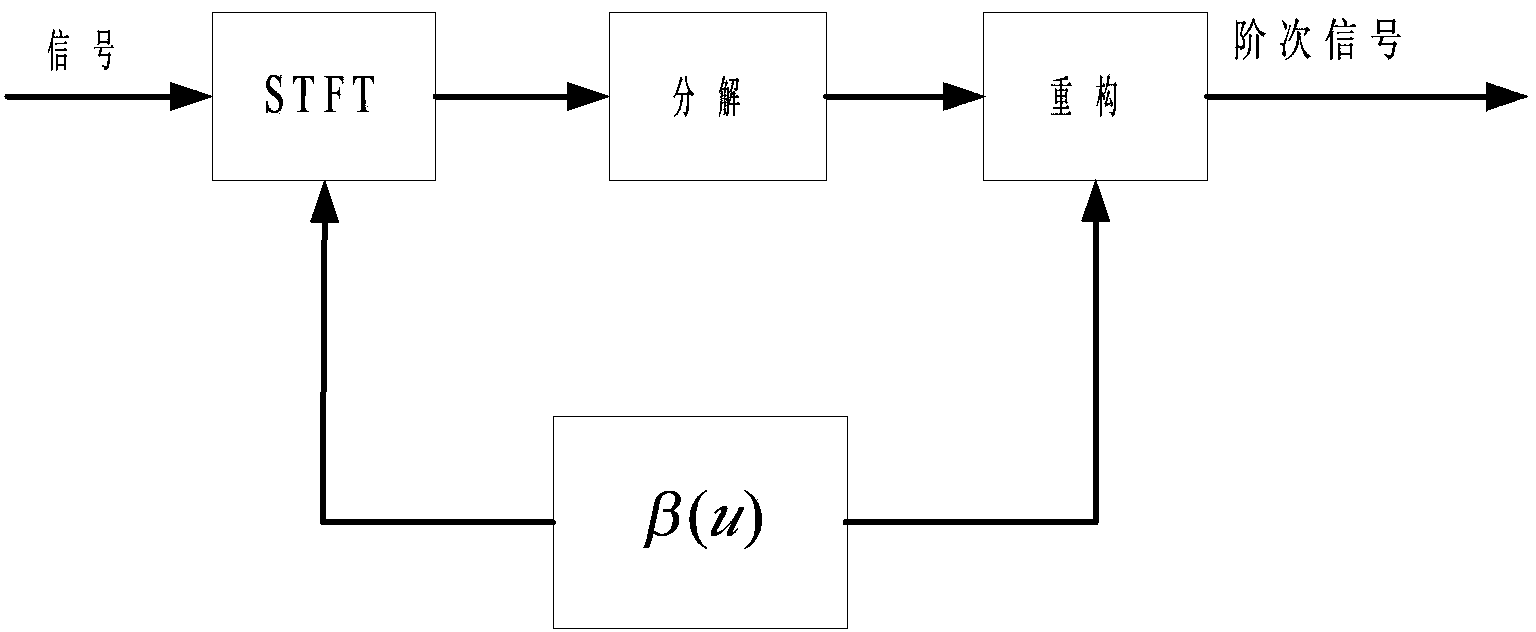

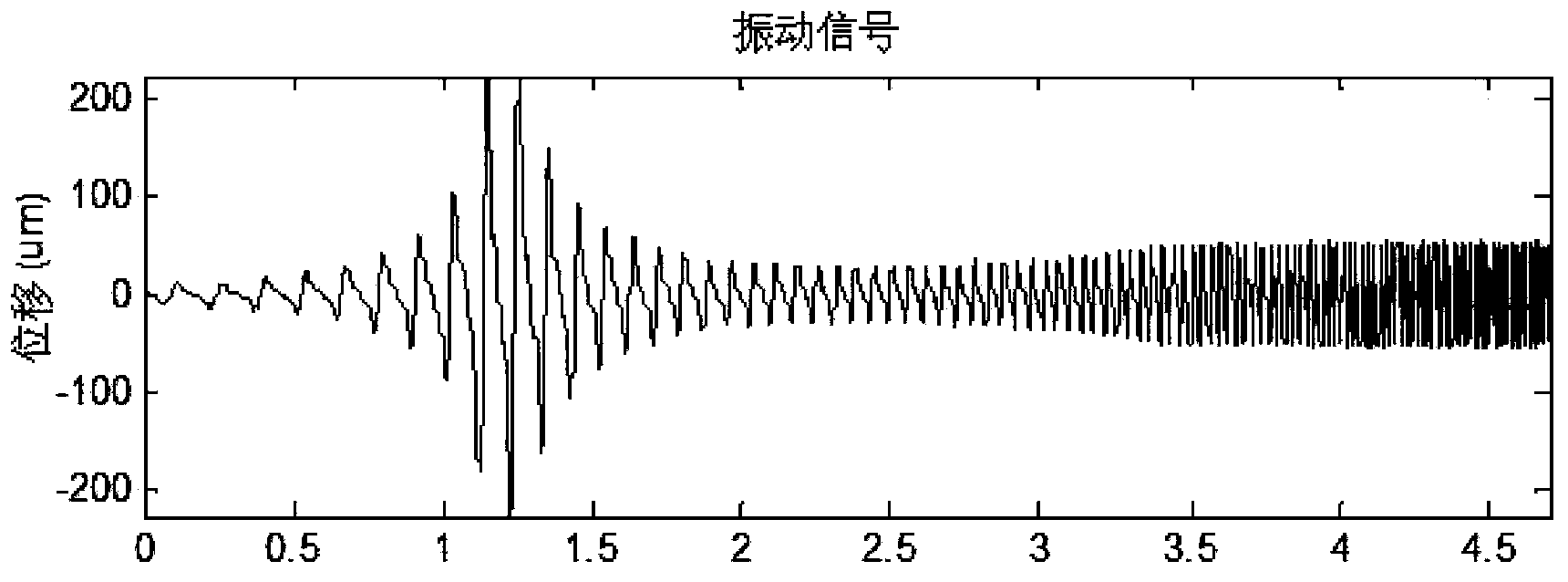

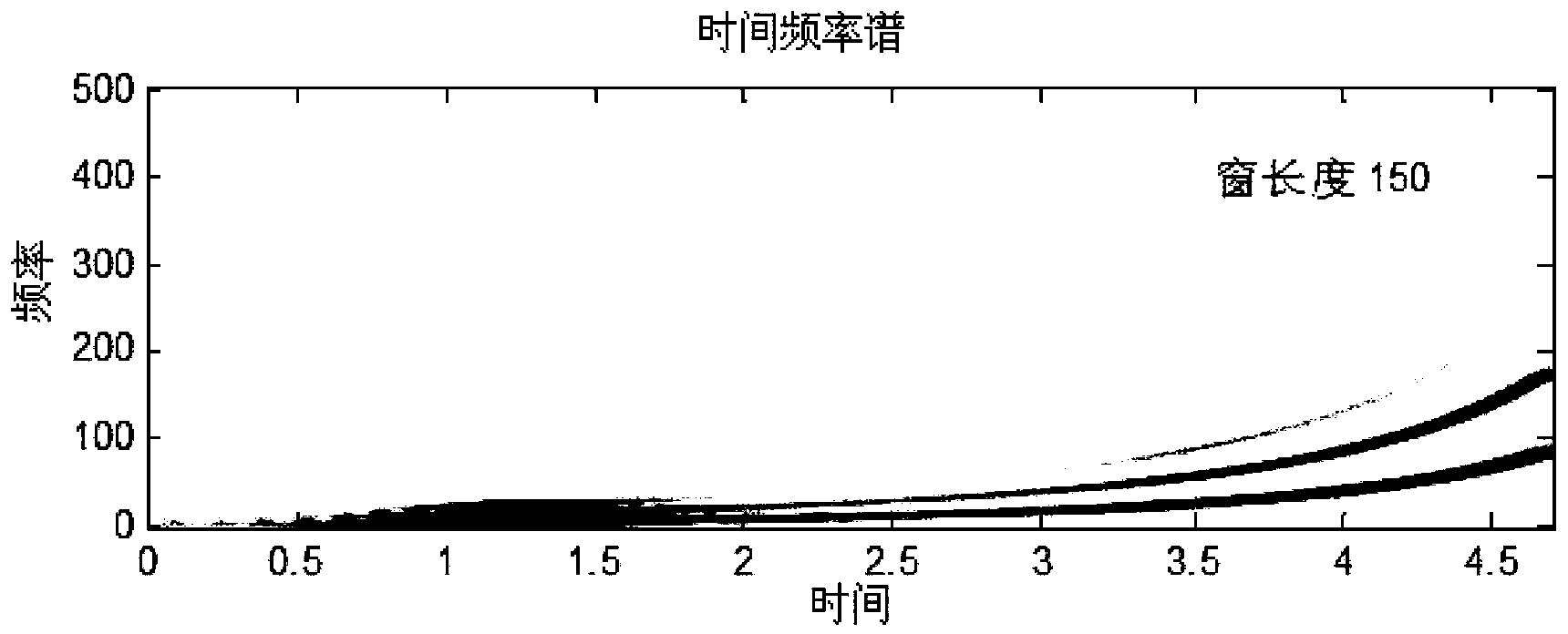

[0030] The principle of the rotating machinery order tracking method based on adaptive STFT is as follows: figure 1 As shown, the scale function of the window function is determined according to the principle that the greater the speed of the window function, the greater the length of the window function. The scale function is substituted into the adaptive STFT, and the original vibration signal is subjected to an adaptive STFT, and the order is extracted from the transformed time-frequency spectrum. Secondary component, perform inverse transformation on the order component to obtain the time-domain curve of the order component, and realize order tracking. The specific steps of this method are as follows:

[0031] 1. Use an eddy current sensor to collect the radial vibration signal of the rotating shaft, denoted as x(n).

[0032] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com