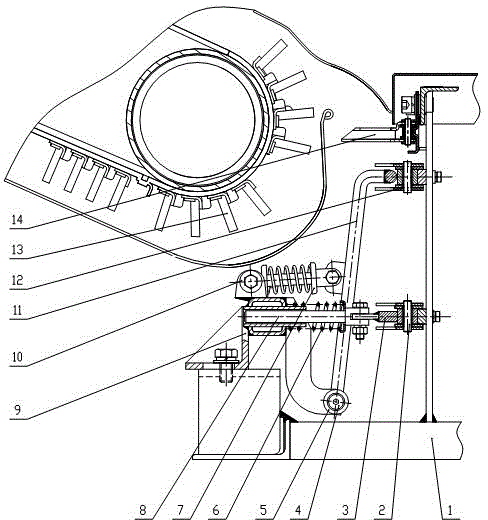

Double straw clamping rods for half-feed combine harvester

A combine harvester and semi-feeding technology, which is applied to agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems that the rice stalks cannot be kept upright, reduce the loss rate in the harvesting process, and the difficulty in adjusting the clamping force, etc., to achieve The effect of simple structure, avoiding food waste, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

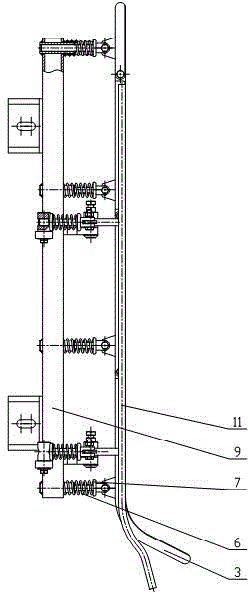

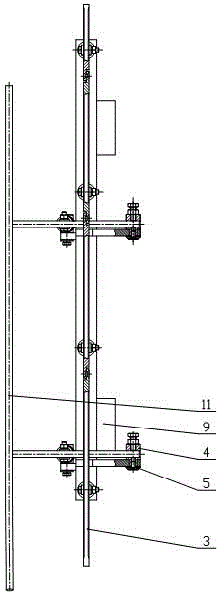

[0011] The present invention will be further described below in conjunction with the accompanying drawings, with reference to the accompanying drawings. The clamping rod Ⅰ is connected to the pin shaft seat through the pin shaft, the spring seat, the spring, and the bolt, and the force provided by the spring compression will make it tightly adhere to the roller of the lower feeding chain. After assembly, the clamping rod Ⅰ It can move back and forth on the axial position of the pin shaft; the clamping rod II is connected to the pin shaft seat through the rotating shaft, end cover, bolt, pin shaft, spring seat, spring and rotating sleeve. After assembly, the clamping rod II can be wound around According to the axial position of the rotating shaft, it swings back and forth, and the force provided by the compression of the spring makes it tightly adhere to the rollers of the grain feeding chain in the middle; finally, the pin shaft seat is fixed to the correct position of the harv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com