Tool holder with high-precision adjustment capability and cutting tool equipped with the same

A high-precision, cutting blade technology, used in milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the quality of the machined surface, large precision control, easy vibration of the cutter body, etc., to improve the adjustment accuracy and adjustment efficiency. , to ensure the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

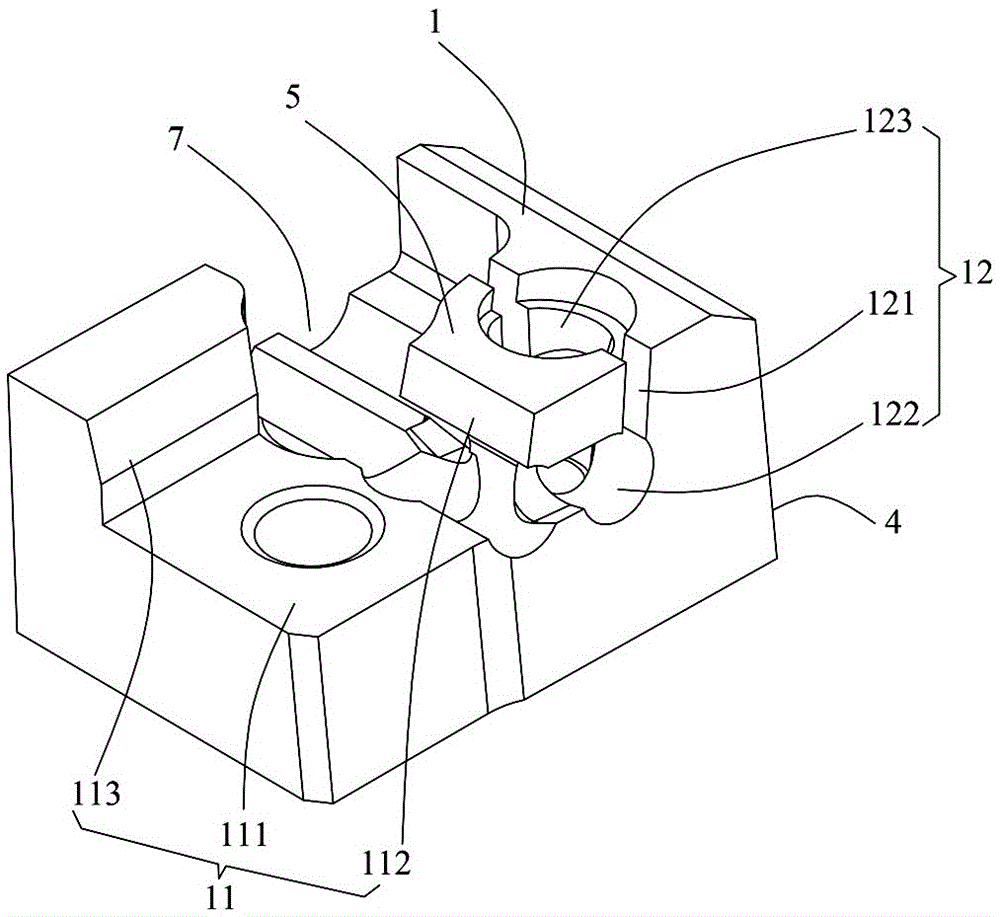

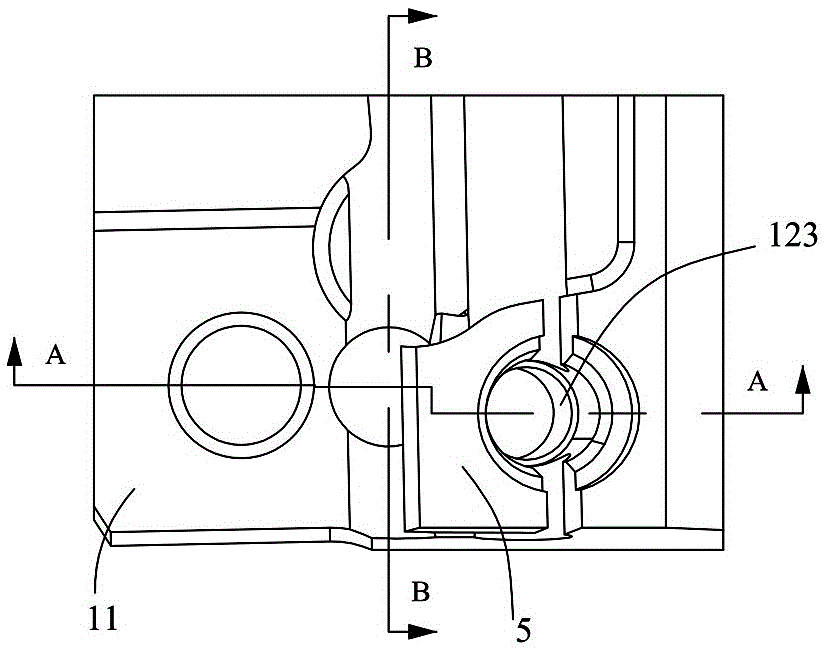

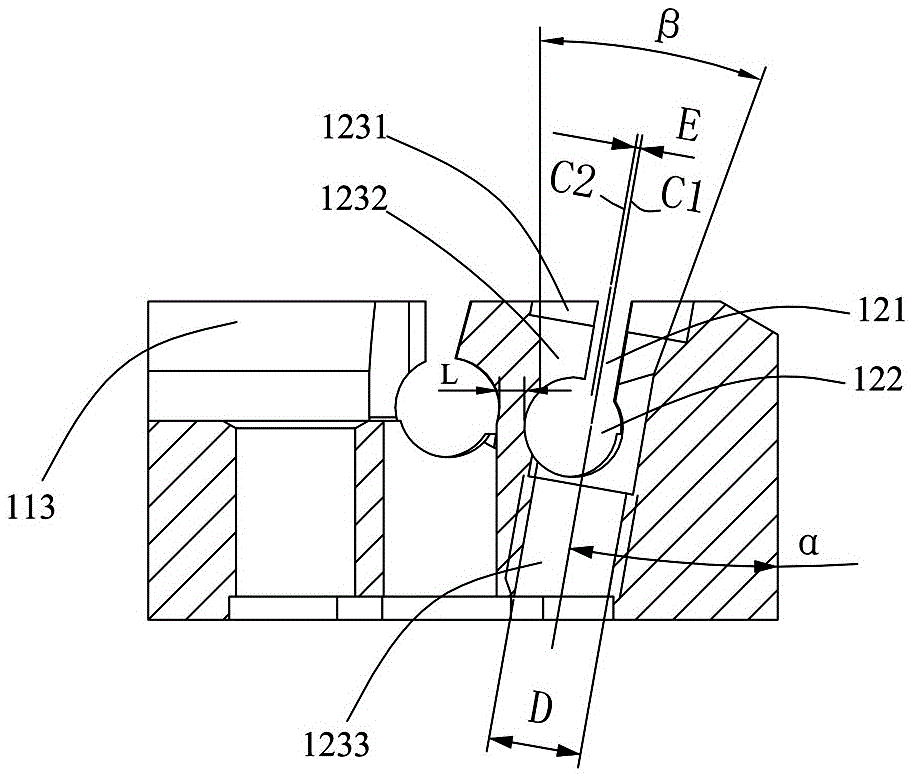

[0028] Figure 1 to Figure 5 It shows the first embodiment of the tool seat with high-precision adjustment capability of the present invention, the tool seat includes a tool seat body 1, and the tool seat body 1 is provided with a knife groove 11 for loading and unloading the cutting blade 2, and the knife groove 11 is set There are bottom locating surface 111, end locating surface 112 and side locating surface 113 for positioning cutting blade 2, and end locating surface 112 and / or side locating surface 113 are equipped with an elastic expansion structure for adjusting the positioning of cutting blade 2. The expansion and tightening structure can change the position of the end positioning surface 112 and / or the side positioning surface 113, thereby adjusting the positioning of the cutting blade 2, realizing the adjustment of the runout of the cutting blade 2, and effectively reducing the range of the runout adjustment to below 0.05mm, greatly Improve the adjustment accuracy a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com