Mechanism for adjusting and aligning through three axes of X, Y and R

A moving mechanism, Y-axis technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the labor intensity of operators, increasing production costs, poor assembly, etc., to reduce the defective rate of product assembly, universal strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

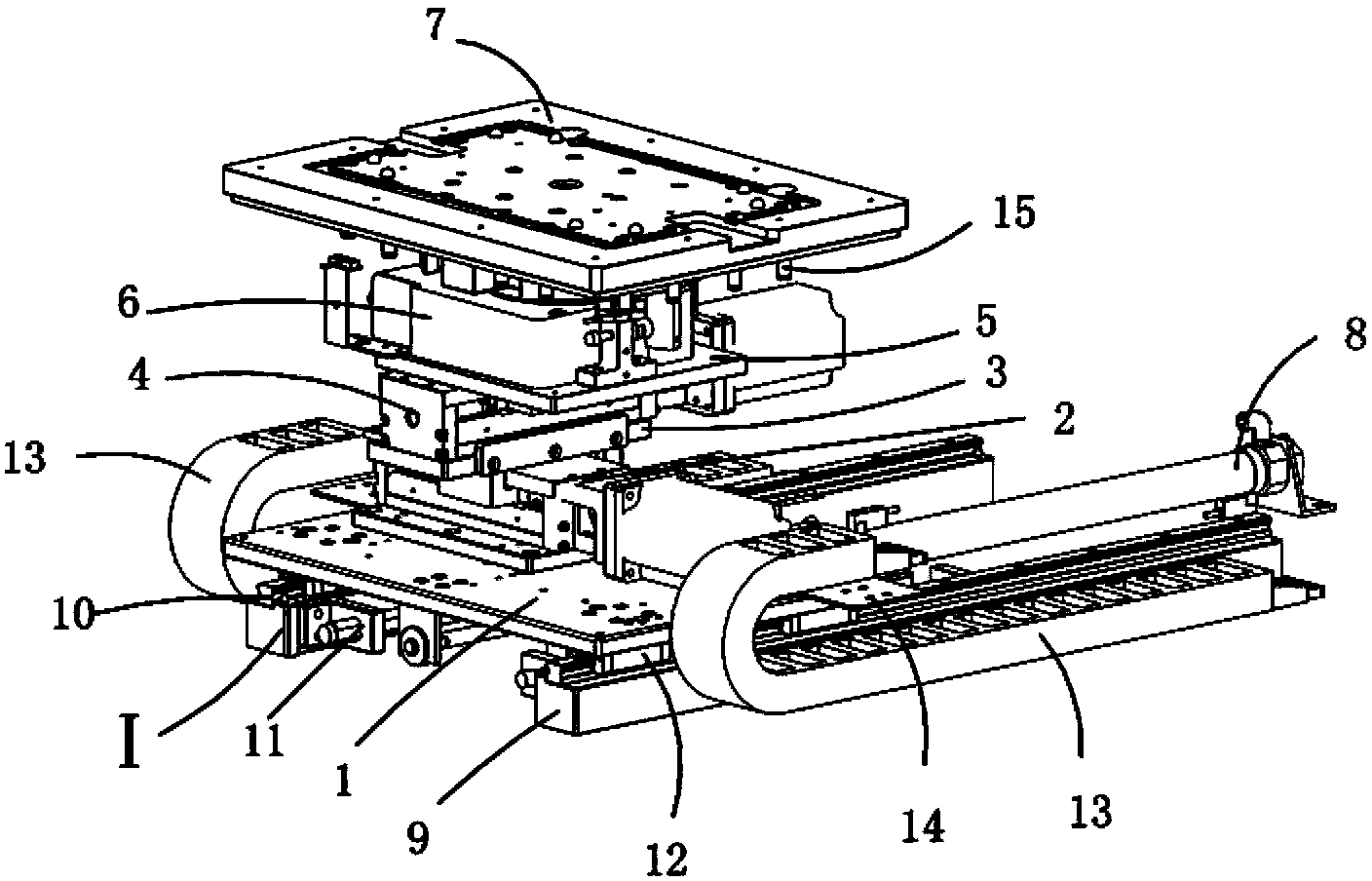

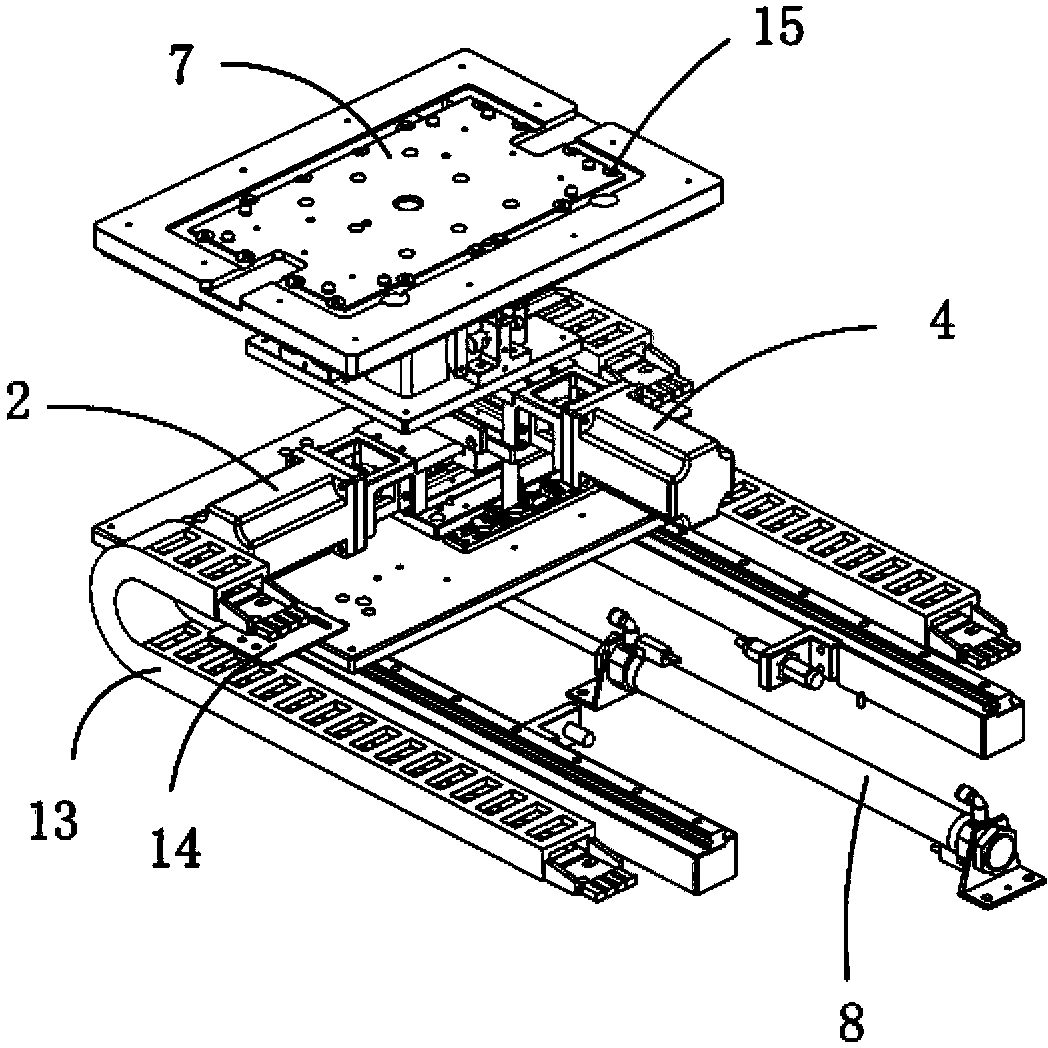

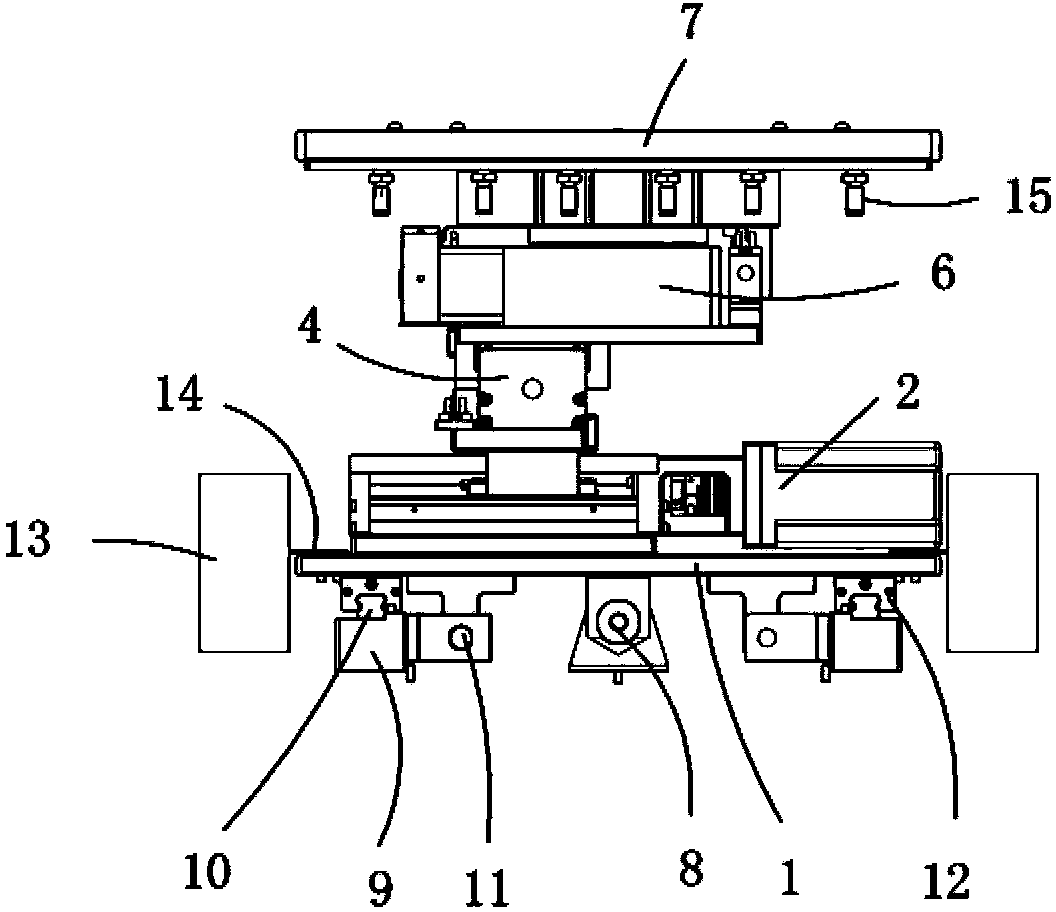

[0016] Examples, see attached Figure 1~3 , an XYR three-axis alignment movement mechanism, which includes a moving module I, a moving plate 1, a Y-axis position adjustment mechanism 2, an XY connecting plate 3, an X-axis position adjusting mechanism 4, an XR connecting plate 5, and an R-axis rotation angle Adjusting mechanism 6 and product positioning platform 7, described mobile module includes displacement cylinder 8, mobile module linear slide rail support 9, mobile module linear slide rail 10 and module mobile positioning mechanism 11, described mobile module linear There are two slide rails, and the two moving module linear slide rails are respectively fixed on the mobile module linear slide rail supports, and the moving module linear slide rails are equipped with sliders 12, and the inner side of each slide rail is connected with Module mobile positioning mechanism; the moving plate is fixedly installed on the slider, driven by the displacement cylinder, the moving plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com