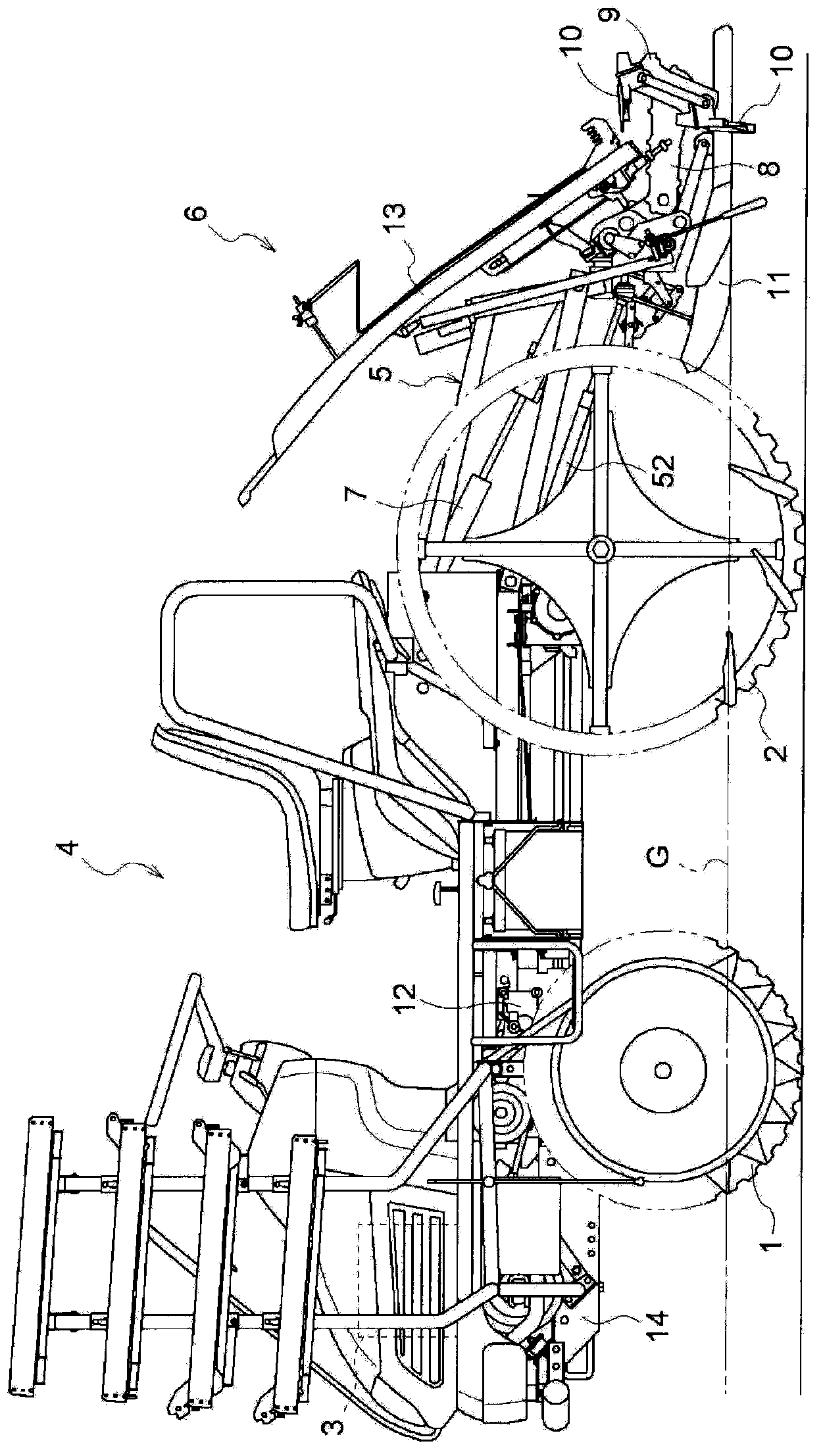

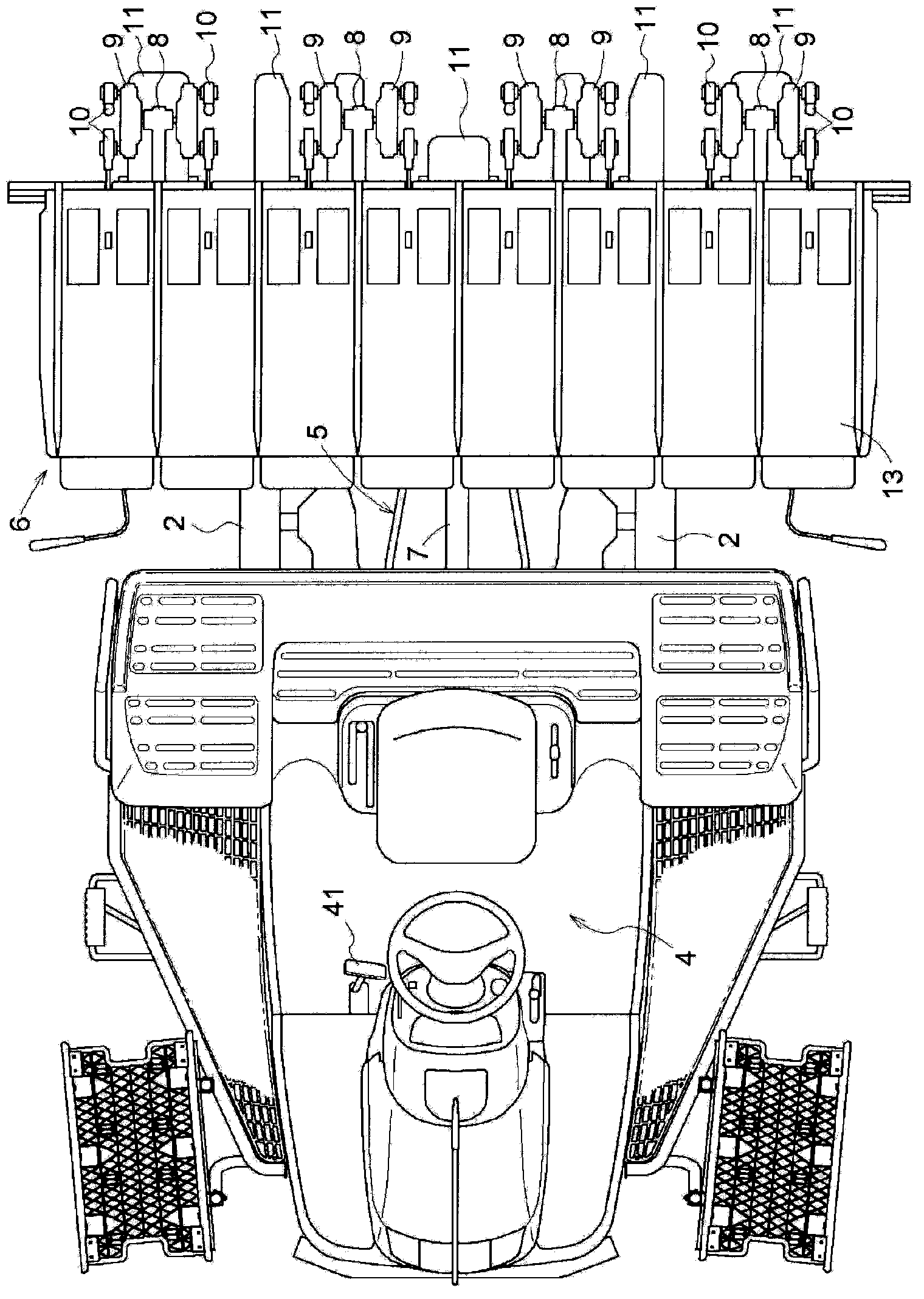

Paddy field operation machine

A technology for working machines and paddy fields, applied in agriculture, transplanting machinery, planting methods, etc., can solve the problems of high cost, decreased durability of the front wheel differential mechanism, complicated structure of the front wheel differential mechanism, etc. Durability, miniaturization, simplification and miniaturization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

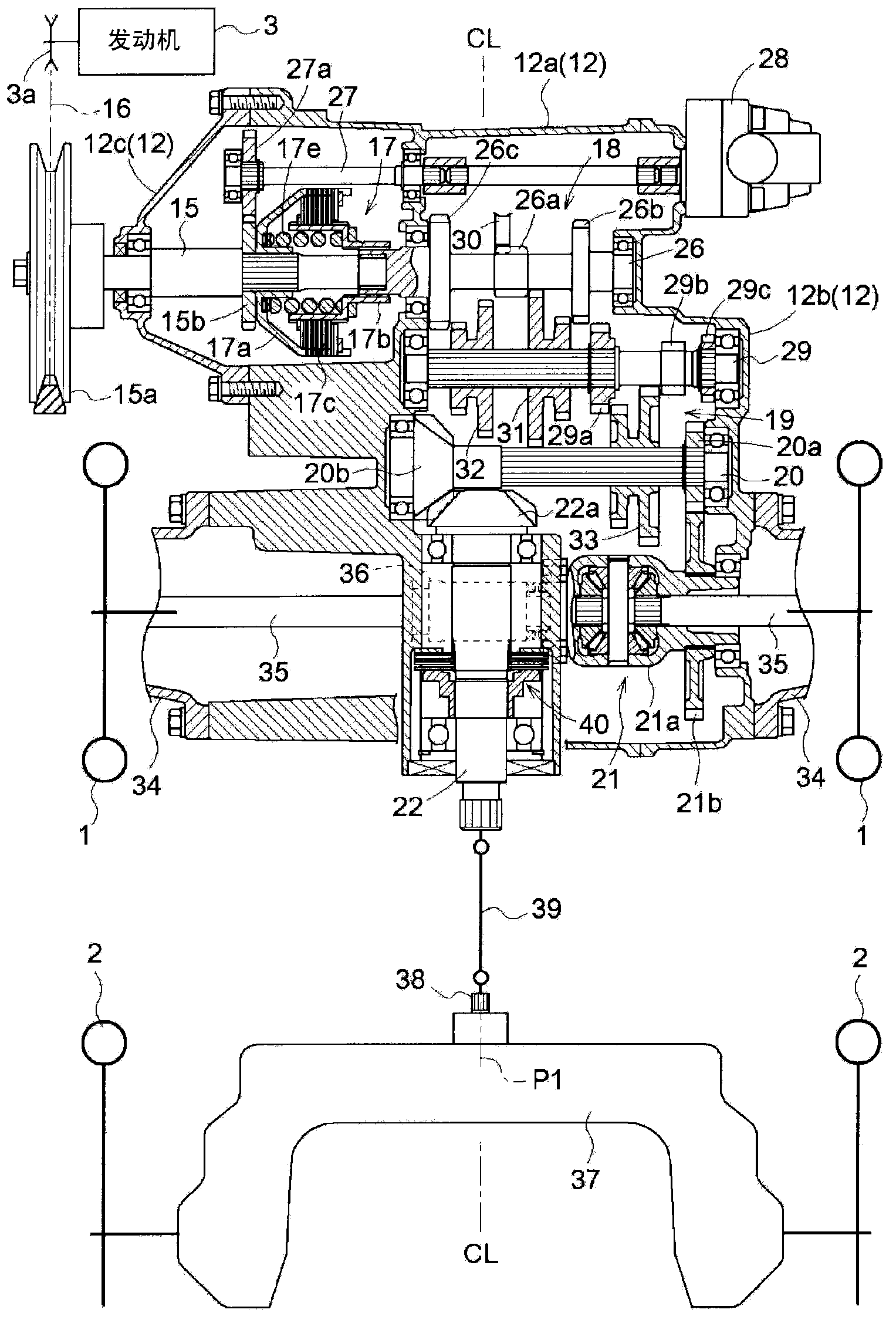

[0179] In the above "specific implementation method" image 3 In the case, the support box part 12c and the input shaft 15 of the gearbox 12 may be provided on the right side of the body with respect to the main body part 12a of the gearbox (the left and right center CL of the body), and the cover part 12b of the gearbox 12 and the front shaft may be provided on the left side of the body. Wheel differential mechanism 21 (spur gear 21b).

[0180] With such a configuration, the spur gear 20a of the travel transmission shaft 20 and the spur gear 21b of the front wheel differential mechanism 21 are provided on the left side of the body with the front wheel differential mechanism 21 interposed therebetween in plan view. The bevel gear 20b of the travel transmission shaft 20, the bevel gear 22a of the rear wheel drive shaft 22, and the rear wheel drive shaft 22 are arranged on the right side of the body through the front wheel differential mechanism 21 in a plan view, and the rear w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap