Bottom open type automatic dumping device

A technology of automatic unloading device and vibration device, which is applied in packaging, transportation and packaging, containers, etc., can solve problems such as bridging and uneven transportation, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

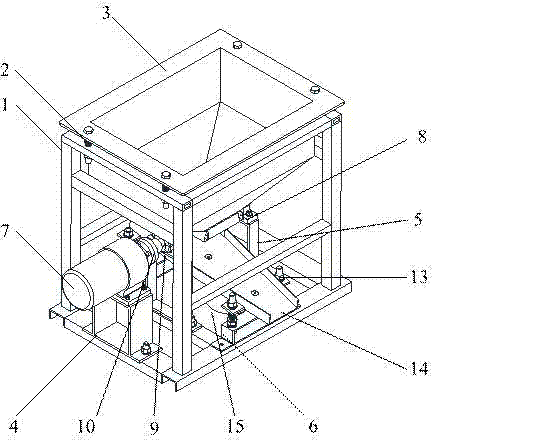

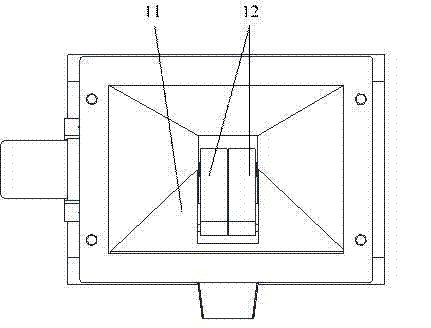

[0017] see figure 1 , figure 2 , a bottom-opening type automatic unloading device, comprising a channel steel frame 1 and a hopper 3 supported and connected by a floating spring 2 above the channel steel frame 1, a bearing seat 8, a motor 7. The bearing housing 8 supports the stirring square shaft 9, which is connected to the motor 7 through the roller chain coupling 10. The hopper 3 is provided with an arch breaking device, and the hopper 3 is provided with a vibrating device below it. The arch-breaking device comprises an opening inclined plate 11 fixed on the inner wall of the hopper 3 with the opening end facing down and a valve-type wall plate 12 connected to the opening of the opening inclined plate 11 by a hinge at one end. The other end of the valve-type wall plate 12 overlaps Be connected on the stirring square shaft 9. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com