Garbage can

A garbage can and garbage technology, applied in the field of garbage cans, can solve the problems of garbage bag tearing, unhygienic, peculiar smell, etc., and achieve the effects of cleaning in a hygienic way, improving work efficiency and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

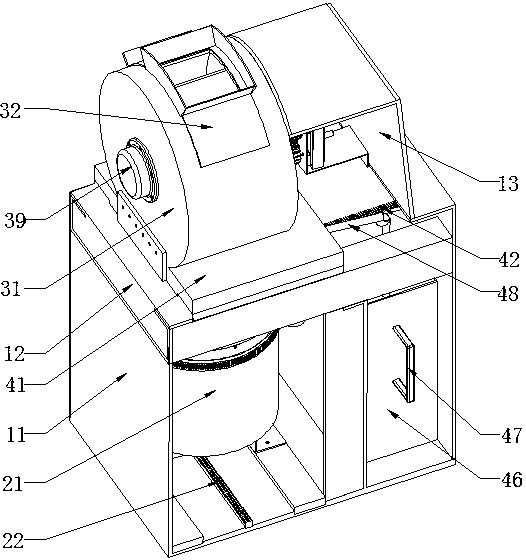

[0032] See attached picture. The garbage bin provided by the embodiment of the present invention comprises an open upper end and a thin-walled barrel body 21 for temporarily storing garbage. The barrel body 21 is installed inside the bracket 11 through the guide rail 225, and is fixedly installed on the bracket through the fixing frame 13. Compression device on and above the barrel.

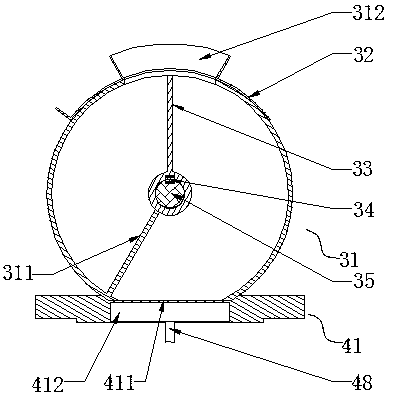

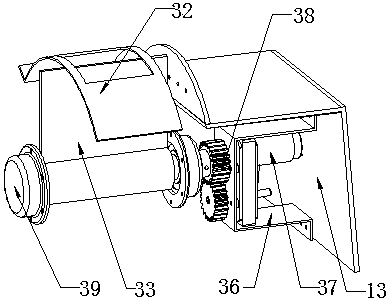

[0033] The compressing device includes a circular housing 31 with an inlet on the top and an outlet on the bottom and a slidable opening and closing plate 41 , the opening and closing plate 41 is installed on the top plate 12 of the support through a guide rail one 45 .

[0034] The housing 31 is fixedly mounted on the top of the opening and closing plate and the outlet of the lower part of the housing is located above the barrel, the top plate is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com