High-shock-resistance and high-photo-oxidation-aging-resistance polyvinyl chloride injection material composition

A material composition and polyvinyl chloride technology, applied in the field of plastic processing, can solve the problems of weak oxygen aging resistance, description, and inability to resist light and oxygen aging for a long time, and achieve enhanced oxidation resistance, widened application fields, and good impact resistance. performance effect

Active Publication Date: 2013-10-23

CHINA PETROLEUM & CHEM CORP

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The light stabilizer of this invention adopts hindered amine light stabilizer and benzotriazole light stabilizer, so that the light stabilizing effect of the material is good, but the oxygen aging resistance is relatively weak, and the antioxidant effect of single antioxidant bisphenol A The effect is not as good as the new compound antioxidant

[0004] CN101967251A discloses a transparent impact-resistant and weather-resistant polyvinyl chloride mixture. The main ingredients of the mixture include 80-90 parts by weight of polyvinyl chloride and 1-20 parts by weight of acrylic transparent impact modifiers. The sum of parts by weight is 100; based on the main material of 100 parts by weight of polyvinyl chloride and acrylic transparent impact modifier, the auxiliary materials added are 0.5 to 8 parts by weight of organotin heat stabilizer, 0-3 parts by weight of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

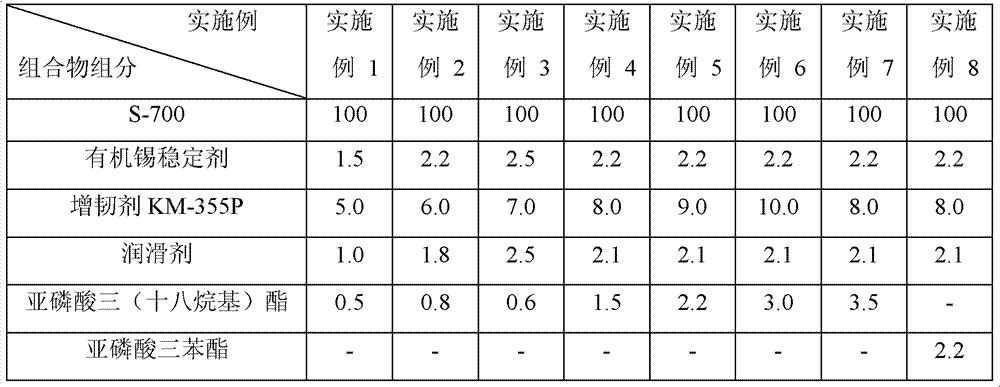

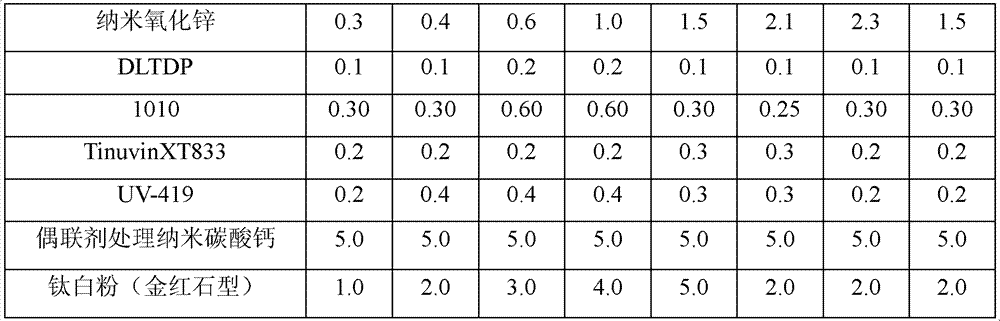

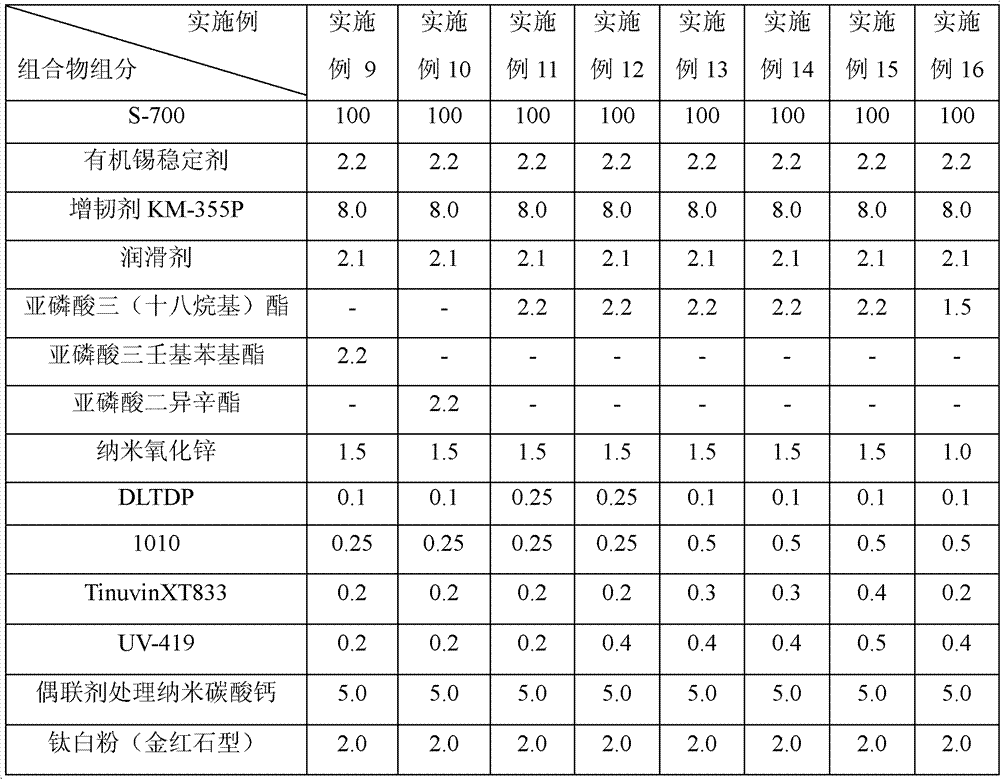

The invention discloses a high-shock-resistance and high-photo-oxidation-aging-resistance polyvinyl chloride injection material composition and belongs to the technical field of plastic processing. The composition comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin, 0.1-0.5 part of heat stabilizers, 5-10 parts of impact modifiers, 0.4-0.9 part of complex antioxidants, 0.7-2.7 parts of complex light stabilizers, 0.5-3.5 parts of phosphite ester and lubricants, 1.5-5.0 parts of rutile titanium dioxide and 3.0-7.0 parts of calcium carbonate auxiliary agents. Compared with the prior art, the high-shock-resistance and high-photo-oxidation-aging-resistance polyvinyl chloride injection material composition, disclosed by the invention, has excellent shock resistance, the early-stage and long-term photo aging resistance and the long-term oxidation resistance; therefore, the composition is suitable for outdoor use and the application field of a toughened polyvinyl chloride injection material is broadened.

Description

technical field [0001] The invention discloses a polyvinyl chloride injection molding material composition with high impact resistance and high light and oxygen aging resistance, belonging to the technical field of plastic processing. Background technique [0002] Polyvinyl chloride (PVC) is a widely used material whose output is in the forefront of the world's resin output. However, the defects of PVC's toughness and poor light and oxygen stability greatly limit the further development and application of PVC. The emergence of toughened polyvinyl chloride successfully solved the shortcoming of high brittleness of polyvinyl chloride products, and expanded its application field to earthquake resistance, anti-ground subsidence and other fields. However, most of the toughened PVC only involves PVC-M pipes, and there is little research on toughened PVC injection molding materials, such as toughened PVC pipe fittings and other toughened PVC injection molding materials. There are ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08L51/00C08K13/06C08K9/04C08K3/22C08K5/524C08K3/26C08K5/134C08K5/372

Inventor 刘浩王晶张新华李静张桦刘容德桂俊杰贾小波孙培培孙丽朋

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com