Installation machine and method for modular installation of upper end socket of settler

An installation method and modular technology, applied in cracking, catalytic cracking, petroleum industry and other directions, can solve the problems of high installation risk, impact on lining construction, and difficult construction, and reduce risks and difficulties, reduce cross-work workload, scientific Effective use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

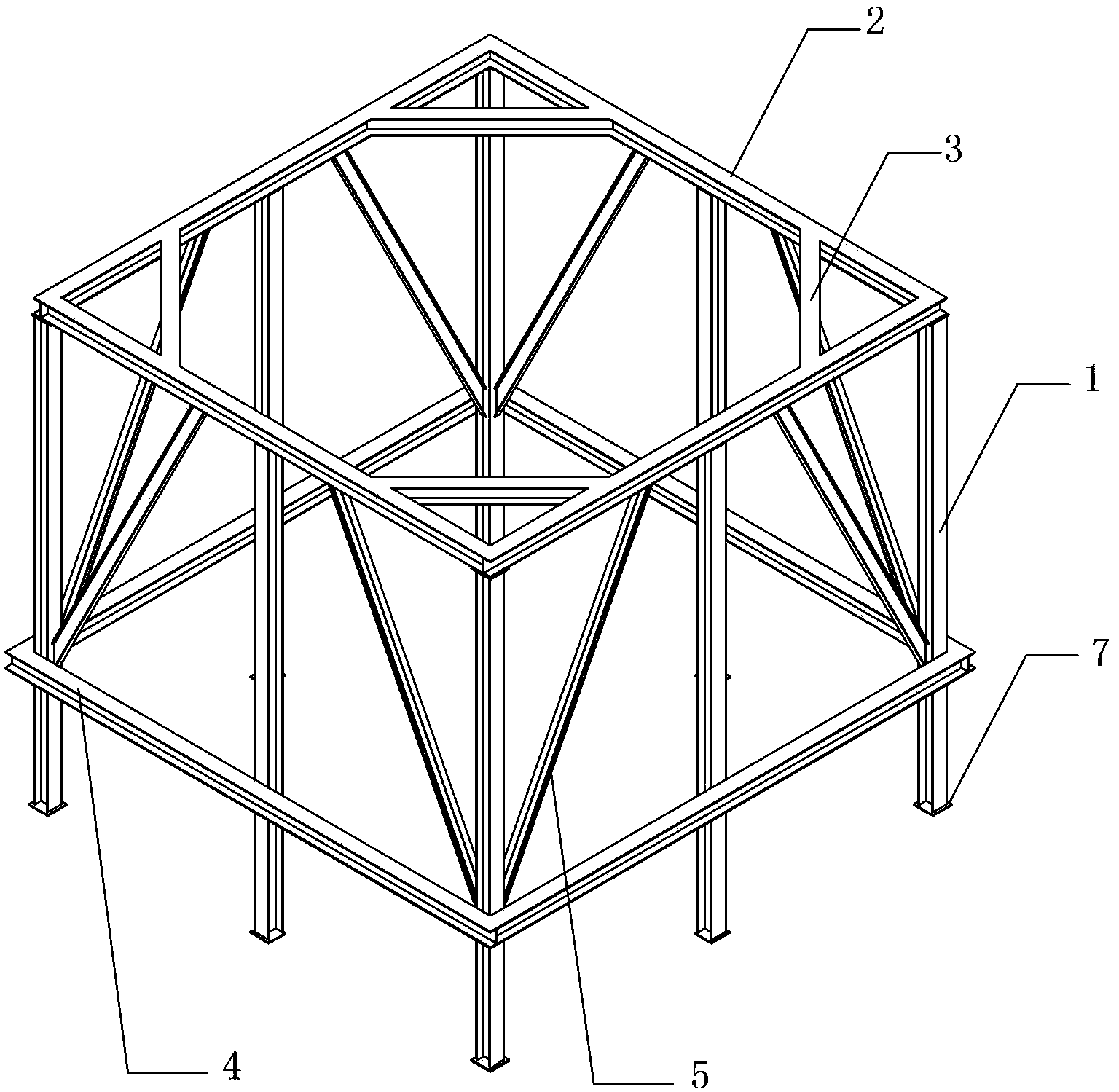

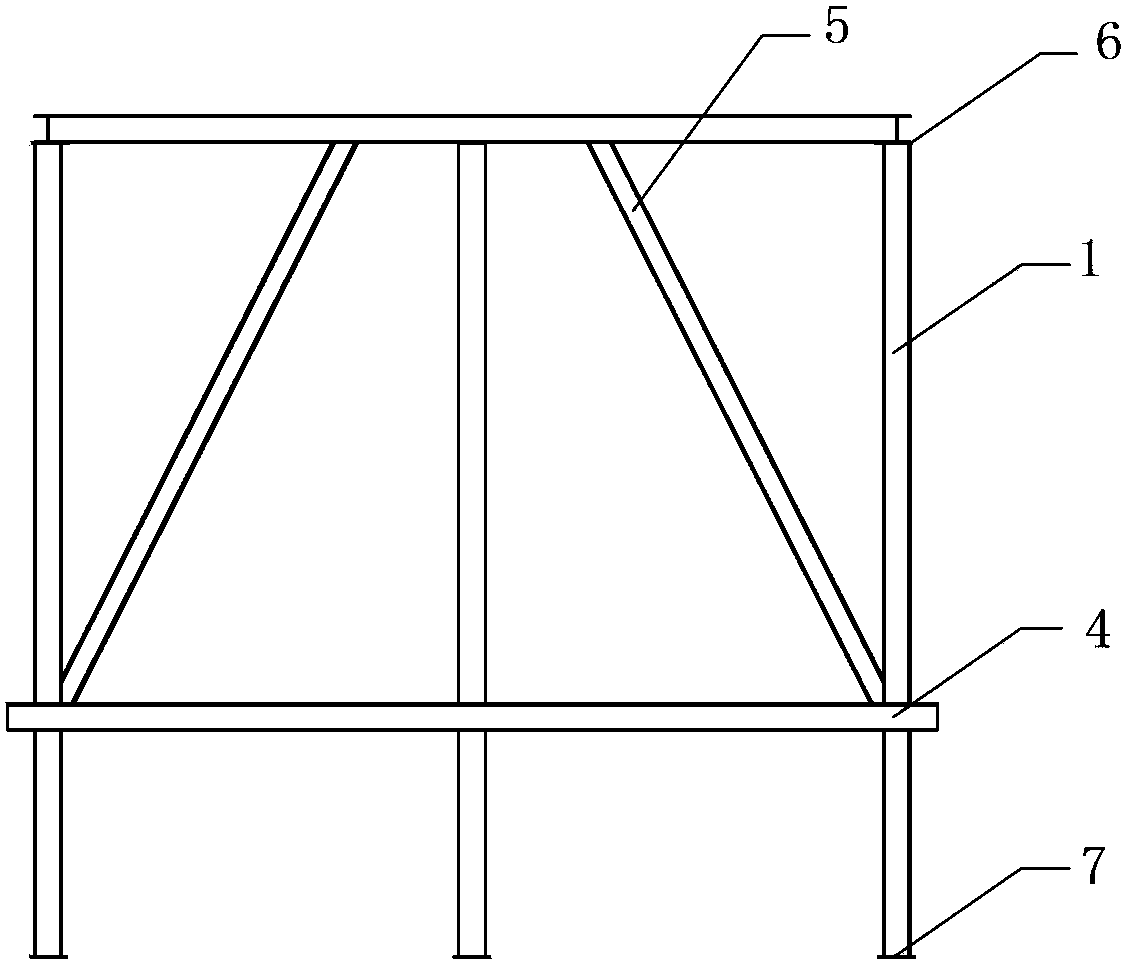

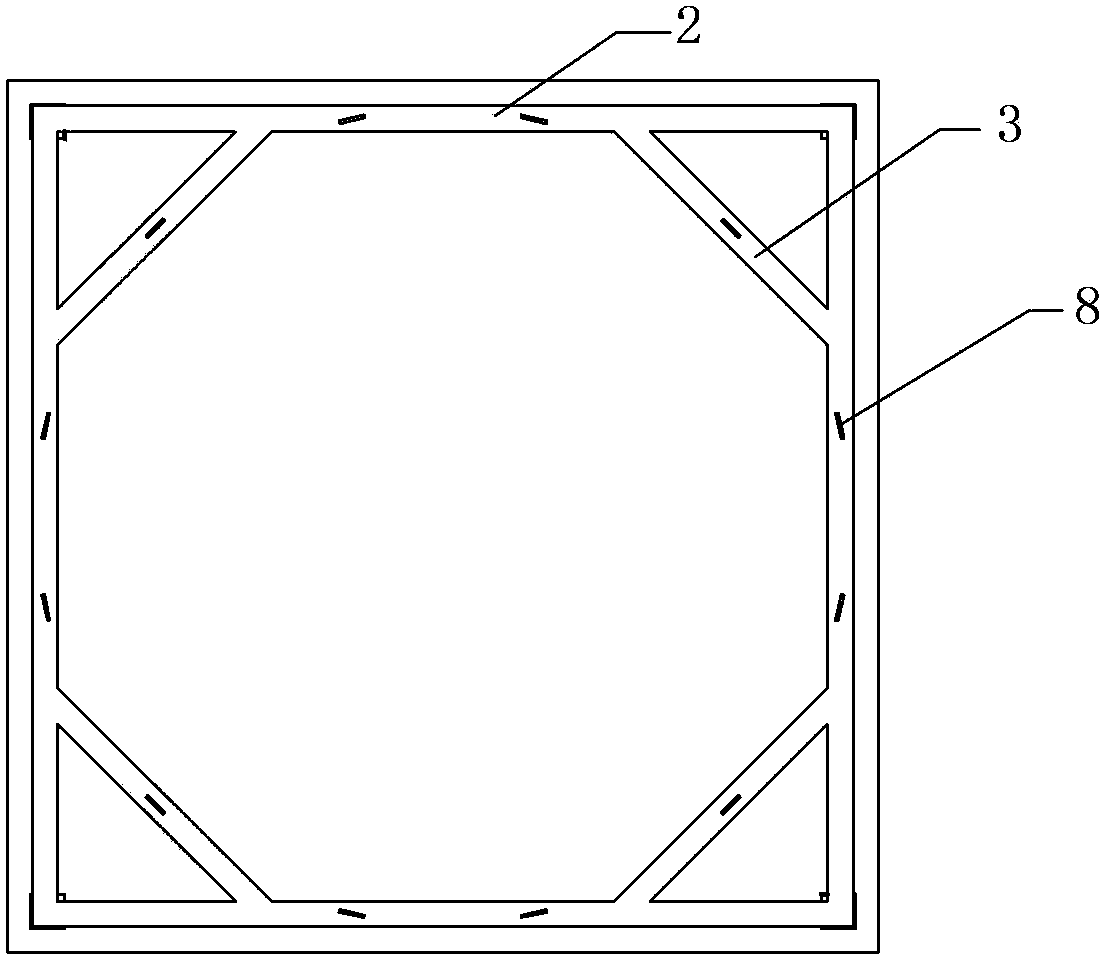

[0011] Further detailed description will be made below in conjunction with the accompanying drawings. Such as figure 1 As shown, an installation machine for the modular installation of the upper head of the settler, including a column 1, a ring beam 2 and a support beam 3, the ring beam 2 is connected end to end to form a frame structure, and the column 1 is perpendicular to the frame ring surface formed by the ring beam 2 , the top of the column 1 is connected to the lower end surface of the ring beam 2, and the two ends of the support beam 3 are respectively connected to the two adjacent ring beams 2. When the connection is completed, the support beam 3 and the corresponding two ring beams 2 form a triangular frame structure to make the structure stronger.

[0012] In this embodiment, in order to increase the stability of the installation machine, the machine can also include a reinforcing beam 4, such as figure 1 , figure 2 As shown, the above-mentioned reinforcing beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com