Assembled jacking pipe

A prefabricated, pipe-jacking technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of restricting the development of pipe-jacking, and achieve the effects of fast and convenient assembly, high structural strength, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

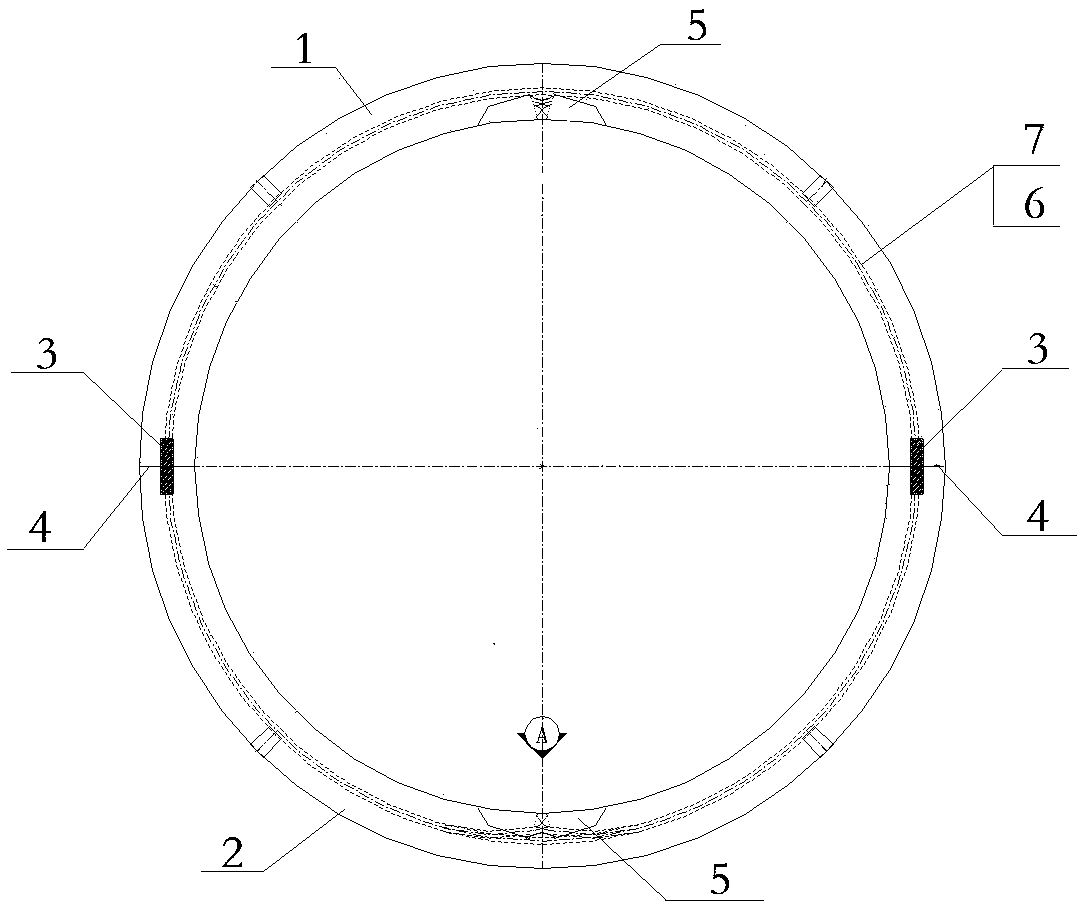

[0023] Embodiment one: if figure 1 As shown, this embodiment specifically relates to a prefabricated reinforced concrete pipe jacking. In the pipe jacking construction project, the current pipe jacking structure is the whole ring jacking method, and the size of the pipe jacking is restricted by the transportation conditions, thus limiting The development of pipe jacking in the field of large diameter tunnels. For this reason, the pipe jacking in this embodiment adopts the form of a plurality of segments assembled into a ring, so as to overcome the difficulties existing in actual transportation.

[0024] Such as figure 1 , 4 , 6, the pipe jacking in this embodiment is specifically assembled from the upper segment 1 and the lower segment 2, the upper segment 1 and the lower segment 2 have the same structure, and can be pre-cast in batches in the factory workshop or construction site .

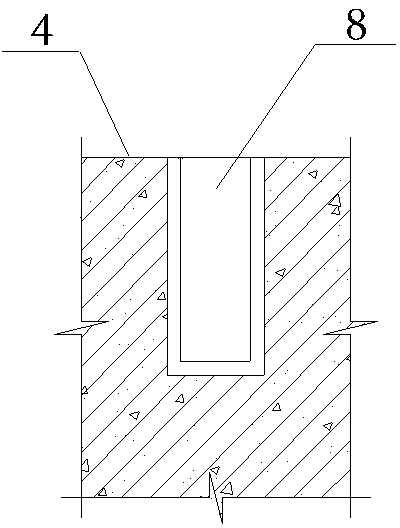

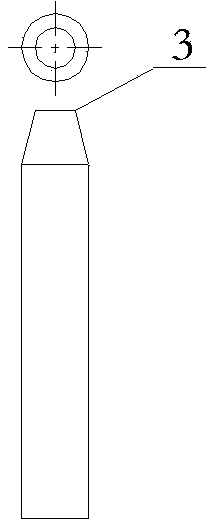

[0025] The following will take the lower segment 2 as an example to illustrate: the lower...

Embodiment 2

[0033] Embodiment two: if Figure 7 As shown, this embodiment specifically relates to an assembled reinforced concrete pipe jacking, which is assembled by three segments 11. Since the circumferential assembly surface between the three segments 11 is not in a horizontal or vertical position, Therefore, the positioning structure of the positioning hole and the positioning pin in the first embodiment cannot be adopted. Therefore, in this embodiment, when each ring jacking pipe is composed of three or more segments 11 assembled in the circumferential direction, the positioning structure of the circumferential assembly surface between adjacent segments adopts concave-convex seam positioning, that is, each There is an outer protrusion 14 on one circumferential assembly surface of the block segment, and an inner groove 13 on the other circumferential assembly surface, and the positions and shapes of the two are matched one by one so that they can be controlled when assembled into a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com