Modular assembly type water purification device and application method thereof

A water purification device and modular technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of increased frequency of backwashing of filter materials, increased filtration load of filter tanks, and unfavorable energy saving and environmental protection. and other problems, to achieve the effect of low operating cost, short construction period and good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

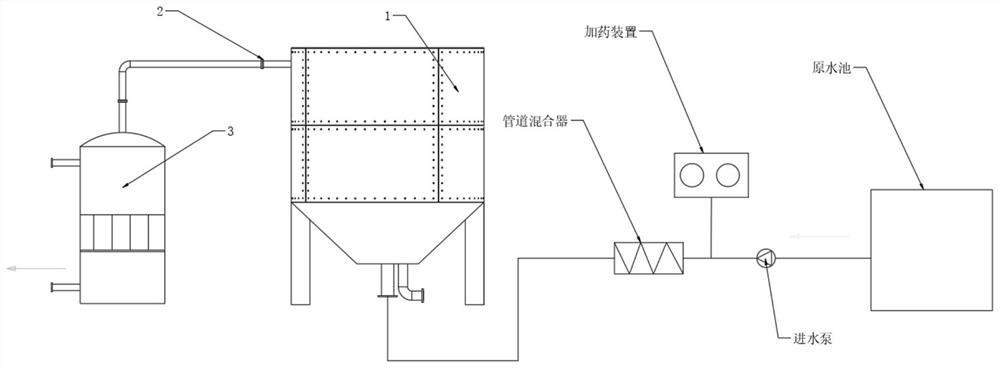

[0041] Step 1: Pharmacy dispensing, prepare PAC solution with a concentration of 10% and PAM solution with a concentration of 0.1%, PAC can be used after mixing and stirring for 30 minutes; due to the limited dissolving ability of PAM, it can be used after stirring for 60 minutes at a high speed, and every 30 minutes Stir for 2 minutes to prevent uneven drug concentration;

[0042] Step 2: Dosing raw water, adding medicine to the raw water that needs to be treated through a diaphragm pump, the turbidity of the raw water is between 900NTU and 1100NTU, and the flocculant PAC (polyaluminum chloride) is added at a dosage of 20mg / L~ 30mg / L, adding coagulant PAM (polyacrylamide), dosage 0.2mg / L~0.3mg / L;

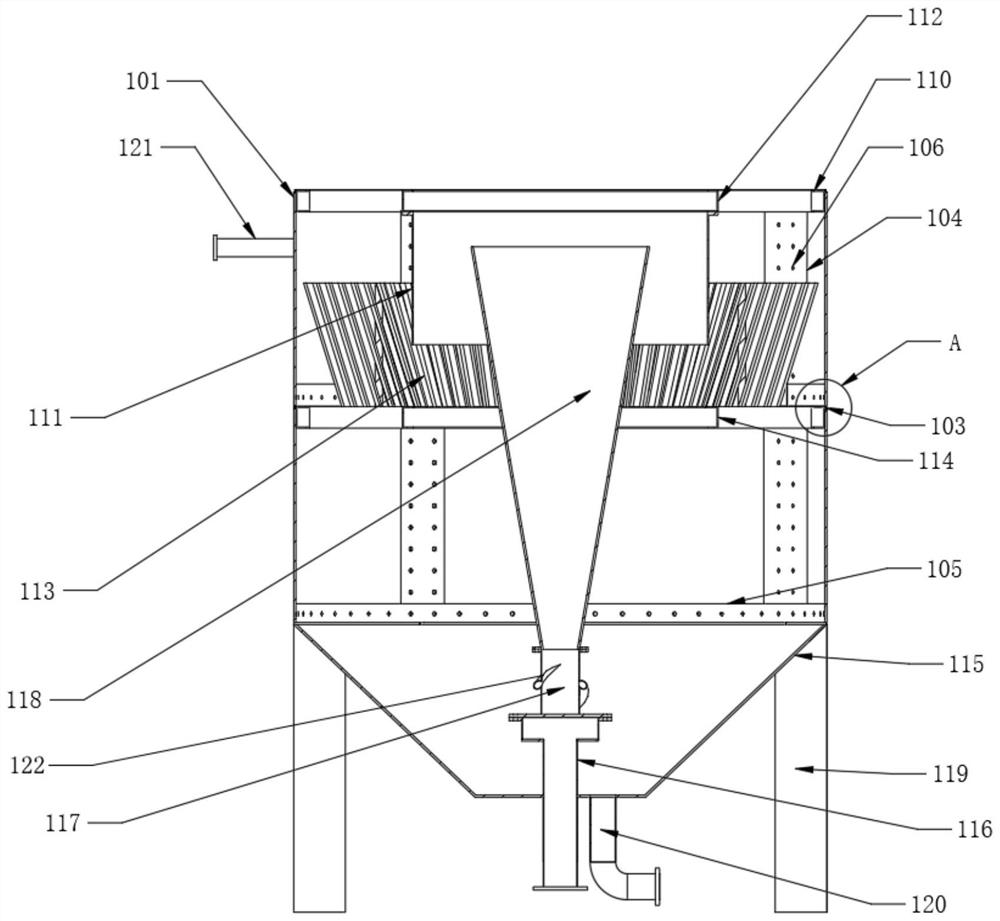

[0043] Step 3: After the raw water is fully mixed with the medicament, it is pumped into the micro-vortex clarifier (swirl cone 118) in the modular water purification device through the water inlet pipe 116;

[0044] Step 4: Suspended matter flocculation, the water enters through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com