Combined-type transition cable leading cage based on cable leading below bridge

A combined type and cable technology, which is applied in the direction of electrical components, pipe supports, pipes/pipe joints/pipe fittings, etc., can solve the problems of too small bending radius of cables, failure of positioning of cables, increased side pressure, etc., to solve the problem of bending radius , safe use, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Best practice:

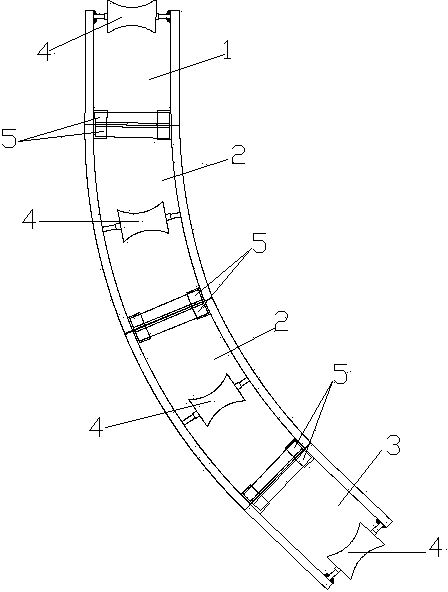

[0023] Refer to attached figure 1 , the combined transition lead cage based on the lead cable under the cable bridge, including a lead lead cage 1, a tail lead cage 2 and more than two middle lead lead cages 3. The first cable cage 1 , the tail cable cage 2 and each intermediate cable cage 3 are composed of a pulley frame 4 , an angle steel frame 5 and steel pipes.

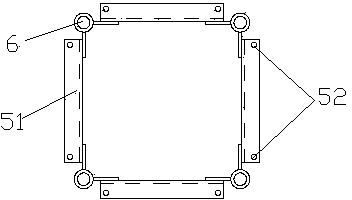

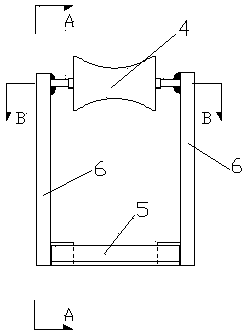

[0024] Refer to attached figure 2 And attached image 3 , the structure of the first cable cage 1 and the tail cable cage 2 is the same, the steel pipe 6 used is a straight steel pipe, the first cable cage 1 and the tail cable cage 2 are made of straight steel pipes 6 and respectively located in the straight Type steel pipe 6 two ends and a pulley frame 4 that is connected with this straight steel pipe 6, an angle steel frame 5 forms. The structure of concrete pulley frame 4 refers to attached Figure 4 , the pulley frame is a square planar frame consisting of four sides and four vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com