Construction method of double-layer slag-proof floor drain

A construction method and floor drain technology, which is applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as blockage and open floor drains without any protection measures, and achieve the effect of simple and convenient construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

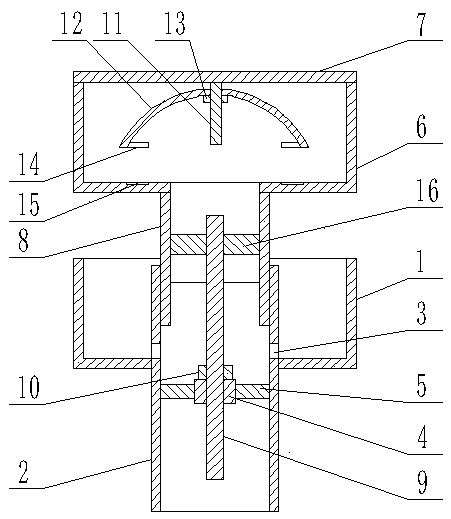

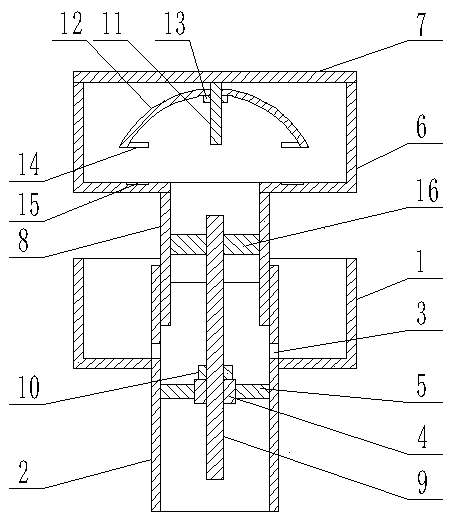

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The construction method of the double-layer anti-slag type floor drain in this specific embodiment comprises the following steps:

[0024] (1) Obtain double-layer slag-proof floor drains, such as figure 1 As shown, it includes the upper floor drain and the lower floor drain arranged up and down. The lower floor drain includes the lower cup body 1 and the water pipe 2. The mouth of the lower cup body 1 is set upwards, and the bottom of the lower cup body 1 is provided with a water outlet along its center line. , the downpipe 2 passes through the downhole and its centerline is set coaxially with the centerline of the lower cup body 1, the bottom of the lower cup body 1 is sealed and fixedly connected with the downwater pipe 2, and the upper end nozzle of the downwater pipe 2 is located in the lower cup body 1, the pipe body of the sewer pipe 2 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com