Construction method and structure of fixing cantilevered I beam by foam

A construction method and technology of I-beam, which are applied in the direction of house structure support, house structure support, and scaffolding for house structure support, etc., can solve the problems such as the formwork sealing is not easy to be compacted, the concrete pouring is not compact, and the anchoring ring cannot be pulled out, etc. The effect of reducing unsafe factors, eliminating quality and safety problems, and reducing pulp leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

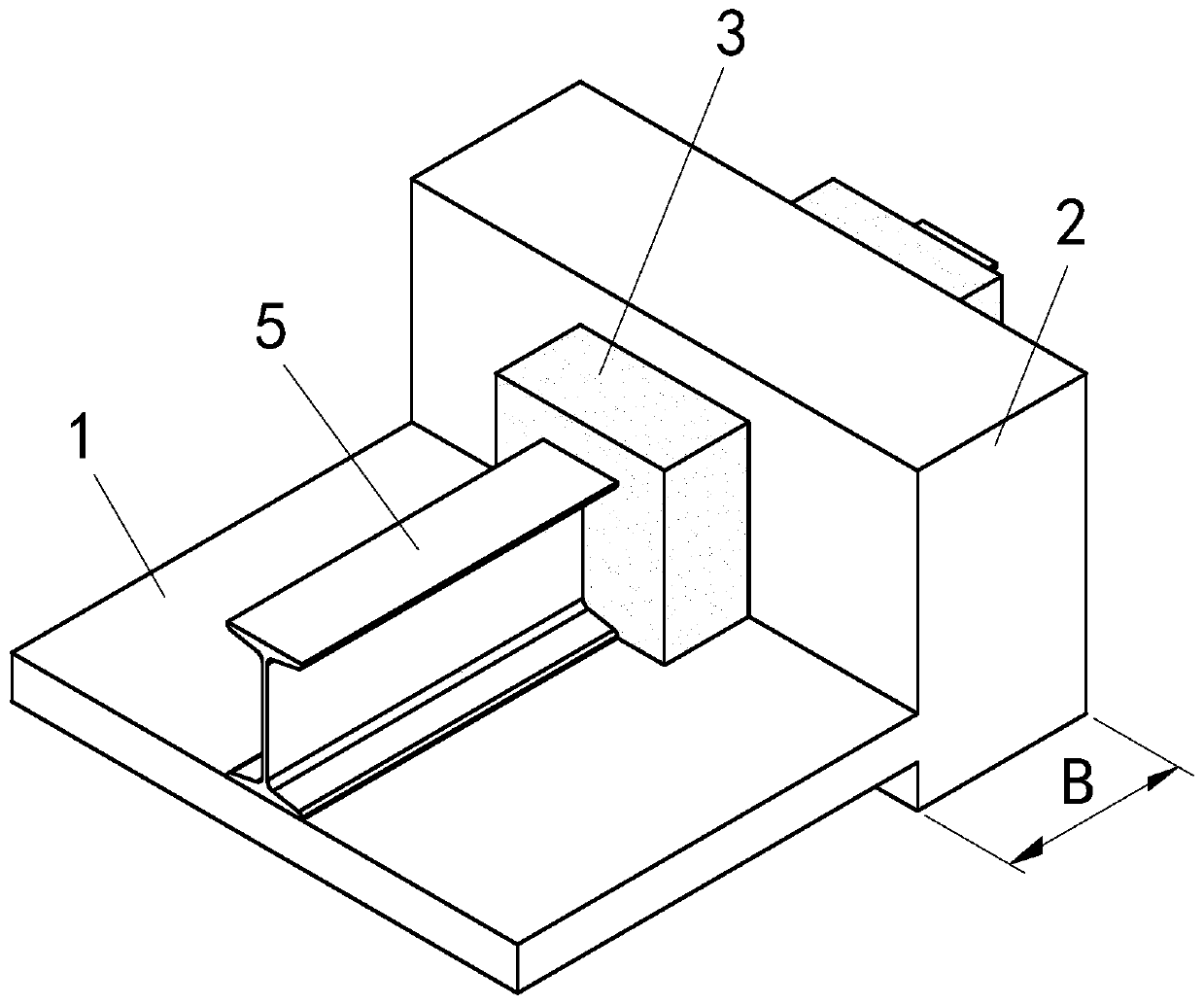

[0023] A kind of construction method of cantilevered I-beam foam fixing of the present invention, such as figure 1 As shown, the method is constructed in the following steps;

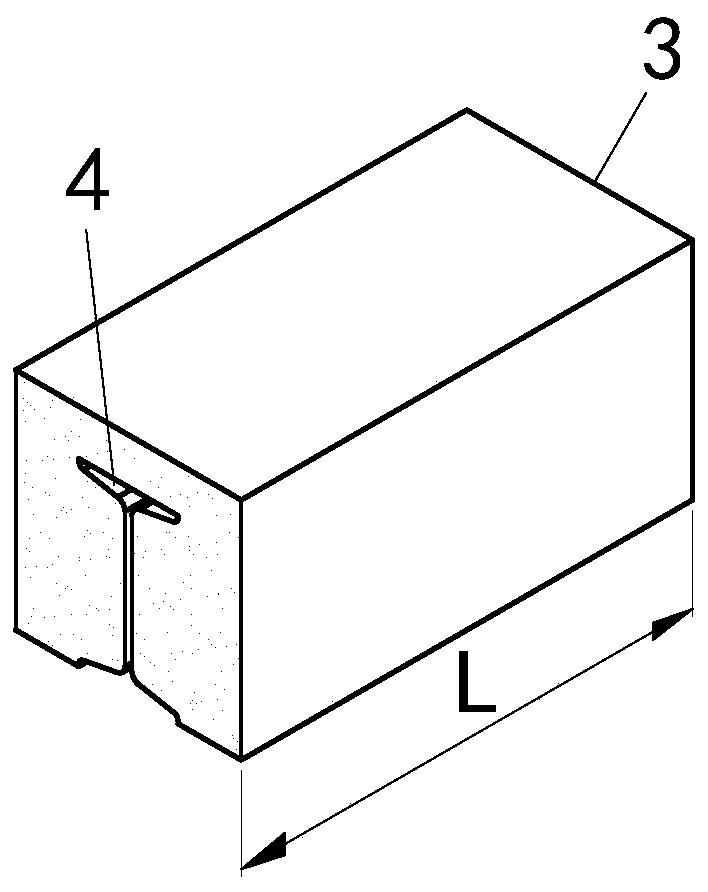

[0024] a. First, customize the foam strip from the manufacturer according to the model of the cantilevered I-steel; the foam strip is provided with an I-shaped notch corresponding to the size of the cantilevered I-steel;

[0025] b. After the foam arrives, according to the thickness of the shear wall to be poured, the foam is cut into short foam joints whose length = thickness of the shear wall B + 200mm;

[0026] c. Insert one end of the cantilevered I-shaped steel into the I-shaped notch of the foam pup joint and penetrate it;

[0027] d. Place and fix the cantilevered I-beam with the foam pup joint on the structural plate according to the requirements of the constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com