Fixed structure for installing secondary pipe and method for installing secondary pipe

A fixed structure and piping technology, applied in cable installation devices, cable installation, electrical components, etc., can solve problems such as cutting slits and grooving, and achieve the effect of fast installation, reduction of material waste, construction period and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

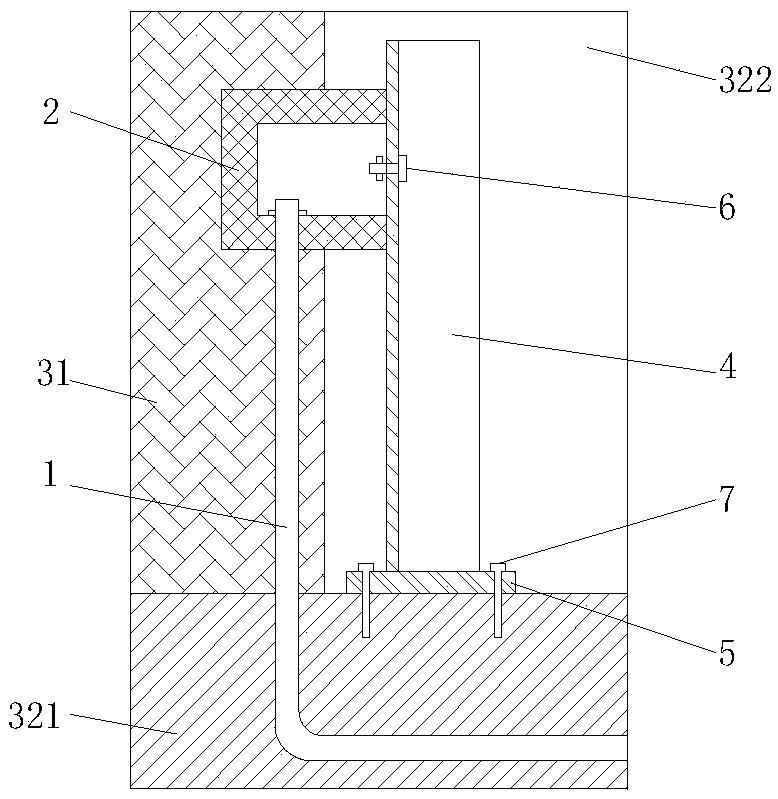

[0047] The secondary piping includes a wire pipe 1 embedded in the first wall surface 31 and a wire box 2 arranged at an end of the wire pipe 1 . Such as figure 1 The shown fixing structure for installing the secondary piping includes a support rod 4, one end of which is fastened to the junction box 2, and the other end is fastened to the built wall.

[0048] The support rod 4 is an angle steel, and the model is ∠40*4.

[0049] A screw hole 21 is provided on the wire box 2, and a first hole matching the screw hole 21 is provided on the support rod 4, and the support rod 4 and the wire box 2 are passed through by a screw 6 The screw hole 21 and the first hole realize fastening connection; as Figure 4 As shown, the wire box 2 is a type 86 wire box. There are two screw holes 21 and two first holes respectively. The diameter of the first hole is 4mm. The screw 6 is a galvanized screw 6 .

[0050] A support base 5 is provided between the support rod 4 and the second wall sur...

Embodiment 2

[0053] Compared with Embodiment 1, the difference of the fixing structure for installing the secondary piping in this embodiment is that: the second wall is the floor 322, and the support rod 4 is placed vertically at this time.

Embodiment 3

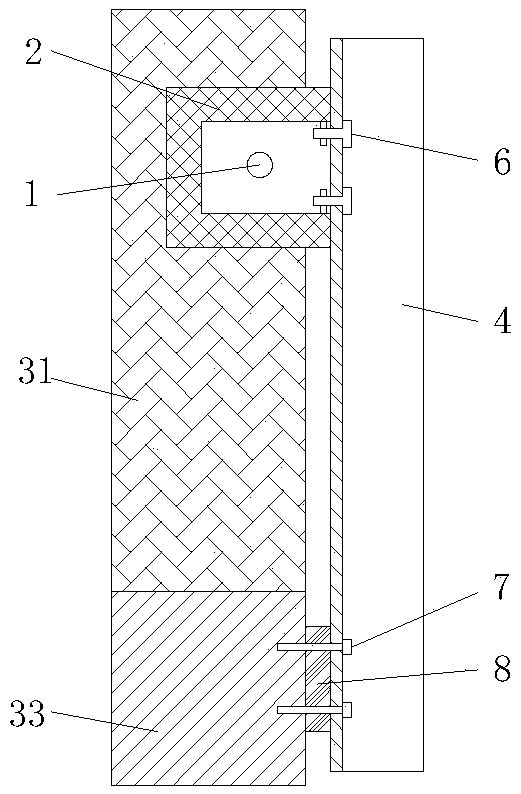

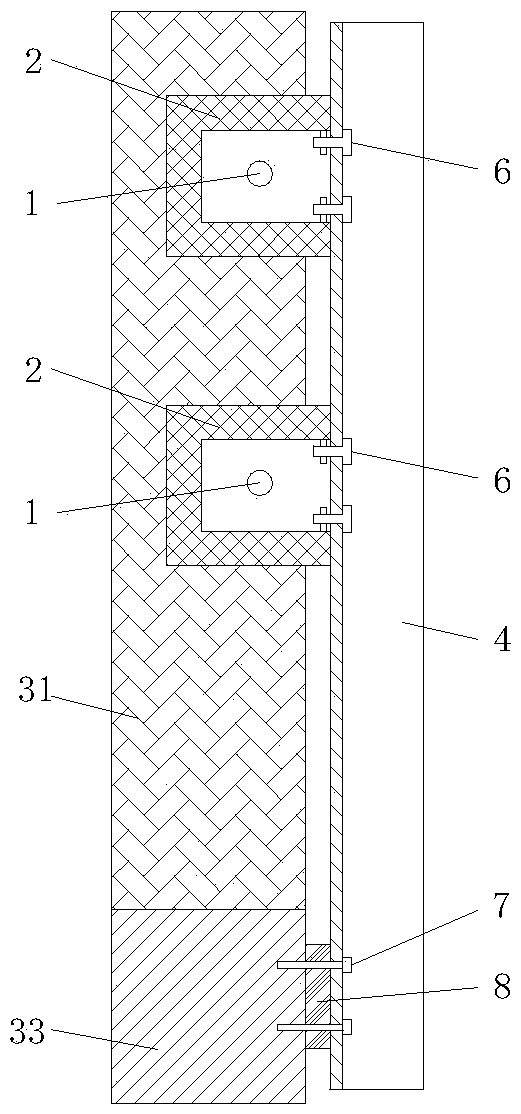

[0055] The secondary piping includes a wire pipe 1 embedded in the first wall surface 31 and a wire box 2 arranged at an end of the wire pipe 1 . Such as figure 2 The shown fixing structure for installing the secondary piping includes a support rod 4, one end of which is fastened to the junction box 2, and the other end is fastened to the built wall.

[0056] The support rod 4 is an angle steel.

[0057] A screw hole 21 is provided on the wire box 2, and a first hole matching the screw hole 21 is provided on the support rod 4, and the support rod 4 and the wire box 2 are passed through by a screw 6 The screw hole 21 and the first hole realize fastening connection; as Figure 4 As shown, the wire box 2 is a type 86 wire box. There are two screw holes 21 and two first holes respectively. The diameter of the first hole is 4mm. The screw 6 is a galvanized screw 6 .

[0058] The support rod 4 is connected with the third wall 33 by expansion screws 7; the third wall 33 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com