Hollow interlayer concrete filled steel tube pouring body with tensile rib, and construction method of the hollow interlayer concrete filled steel tube pouring body

A technology of concrete filled steel tube and construction method, which is applied in construction, artificial islands, water conservancy projects, etc., can solve the problems of insufficient concrete restraint and weakened bearing capacity, and achieve good economic benefits, slow down the buckling of the outer drum, and light weight.

Pending Publication Date: 2019-04-02

CENT SOUTH UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hollow interlayer concrete-filled steel tube concrete casting body has the defect of insufficient restraint of the inner and outer steel pipes on the concrete, especially the inner steel tube; and with the increase of the hollow ratio, the bearing capacity of the hollow sandwich concrete-filled steel tube concrete casting body will be significantly weakened

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

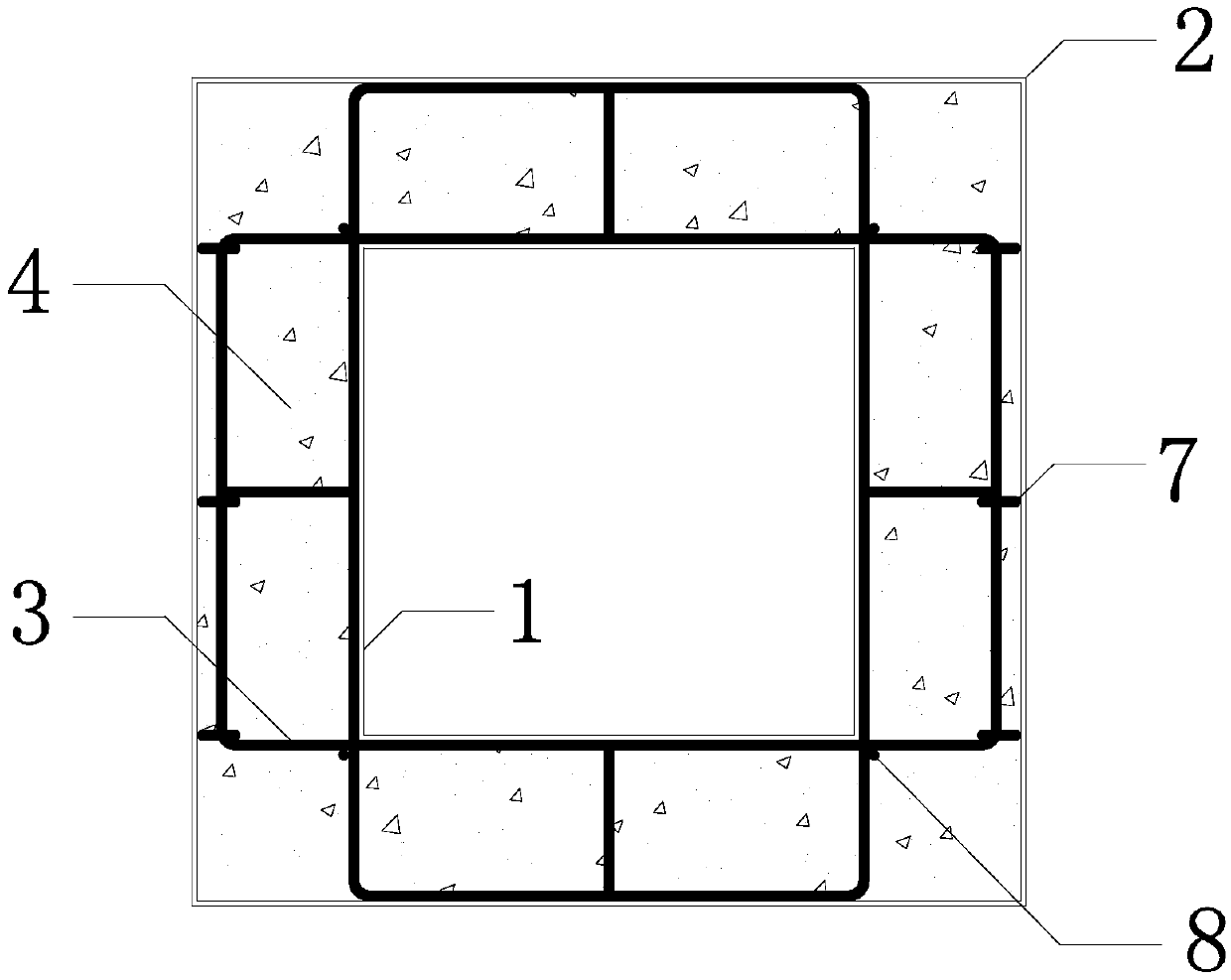

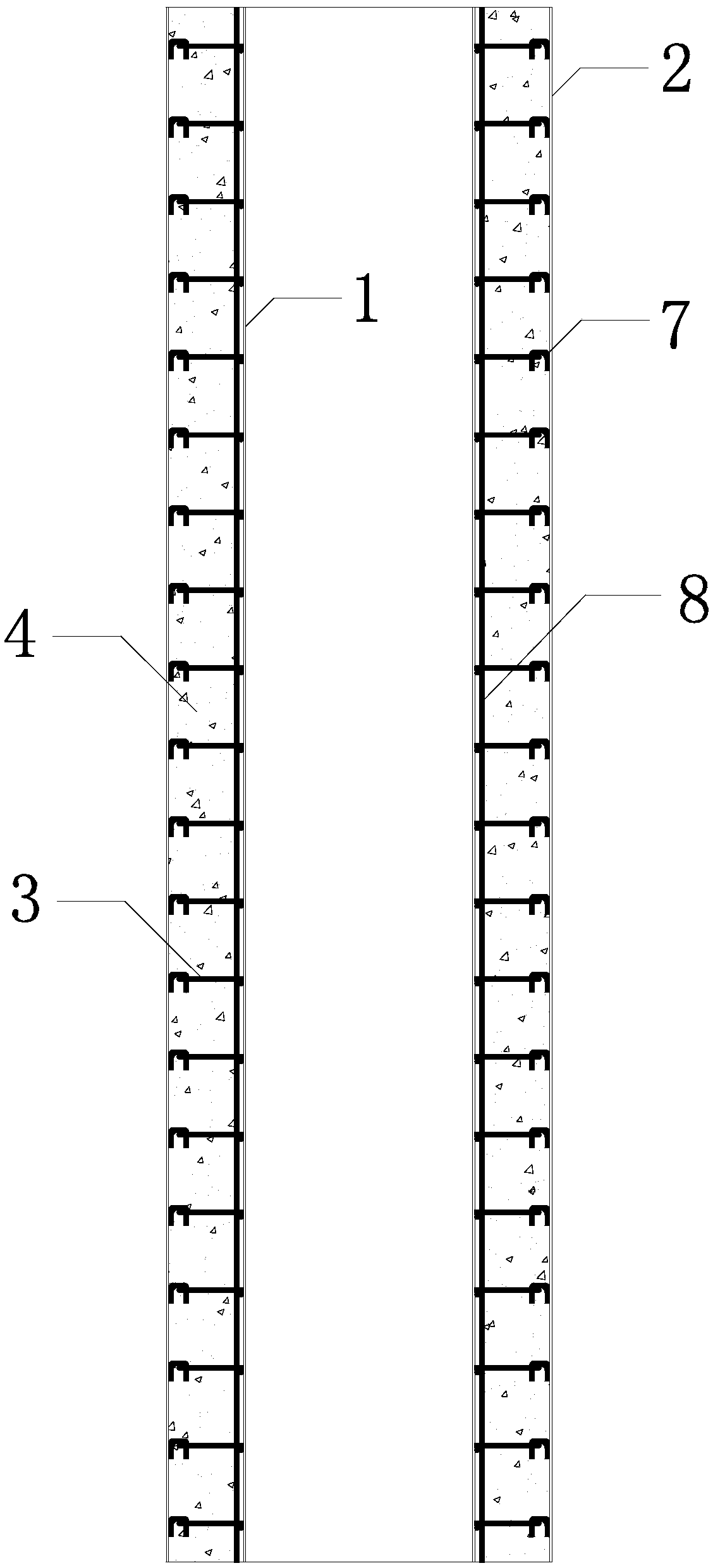

[0071] Such as Figure 9 , Figure 10 , Figure 11 As shown, adopt the structure and method of the present invention, the hollow interlayer belt reinforced steel pipe concrete high pier of making. Concrete piers can be rectangular, circular, oval or round-ended in cross-section.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

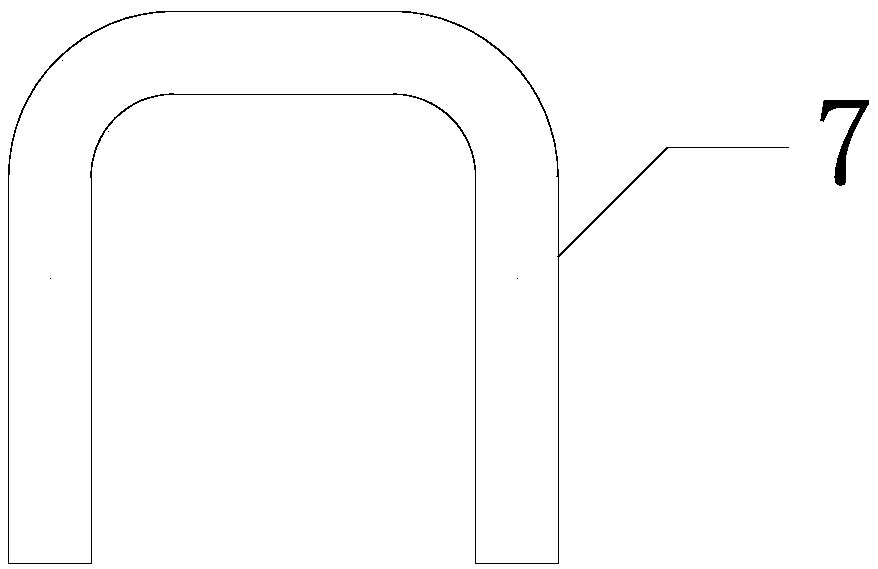

The invention discloses a hollow interlayer concrete filled steel tube pouring body with tensile ribs, and a construction method of the hollow interlayer concrete filled steel tube pouring body. The hollow interlayer concrete filled steel tube pouring body comprises an inner steel tube and an outer steel tube which are concentric and are formed by a plurality of straight steel plate components inassembled and welded modes, wherein bent hooks are welded to the two straight steel plate components constituting the outer side steel tube, concrete is poured into a hollow interlayer formed by the two concentrically-placed steel tubes, the hollow interlayer concrete filled steel tube pouring body further comprises bidirectional opposite-pulling stirrups arranged in the hollow interlayer, the opposite-pulling stirrups are evenly arranged in the height direction of the steel tubes, the opposite-pulling stirrups and positioning longitudinal ribs are manufactured into the form of a steel reinforcement cage, and through a construction method of combining welding with bent hook sleeving, the stirrup cage is effectively connected with the interlayer inner surfaces of the steel tubes with the hollow interlayer. Construction operation is easy and convenient, the defects that the restraint effect of the inner steel tube and the outer steel tube of the hollow interlayer concrete filled steel tube pouring body on the concrete is insufficient, and the inner layer steel tube has no restraint effect on the concrete are overcome, the bearing capacity of the hollow interlayer concrete filled steel tube pouring body is improved, and the structural performance of the hollow interlayer concrete filled steel tube pouring body is further optimized.

Description

technical field [0001] The invention relates to the technical field of construction, in particular to a hollow interlayer steel pipe concrete pouring body with tension bars and a construction method thereof. Background technique [0002] Concrete-filled steel pipe casting is a building component made by filling concrete in steel pipes. It has both excellent mechanical characteristics of steel and concrete. Commonly used structural members. [0003] Among them, the hollow interlayer concrete-filled steel pipe casting body is a new type of composite column formed by pouring plain concrete between the inner and outer two-layer concentric steel pipes. In addition to the high compressive bearing capacity, good plasticity and toughness of the traditional steel pipe concrete pouring body, it is convenient for construction. In addition to the advantages of good fire resistance and cost saving, it also has the characteristics of light weight, high bending rigidity, good seismic perf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04C3/36E01D19/02E01D21/00E02B17/00E04H12/00E02D5/34

CPCE01D19/02E01D21/00E02B17/00E02D5/34E04C3/36E04H12/00

Inventor 丁发兴

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com