Concrete cylinder wall adopting internal pulling type disassembly-free composite formwork and construction method of concrete cylinder wall

A composite formwork and inner-drawing technology, which is applied in the processing of building materials, building types, buildings, etc., can solve problems such as unstable quality and safety performance, small space for exterior finishes, and slow construction progress, and achieve inner-drawing structures Solid and firm, simple and convenient construction operation, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

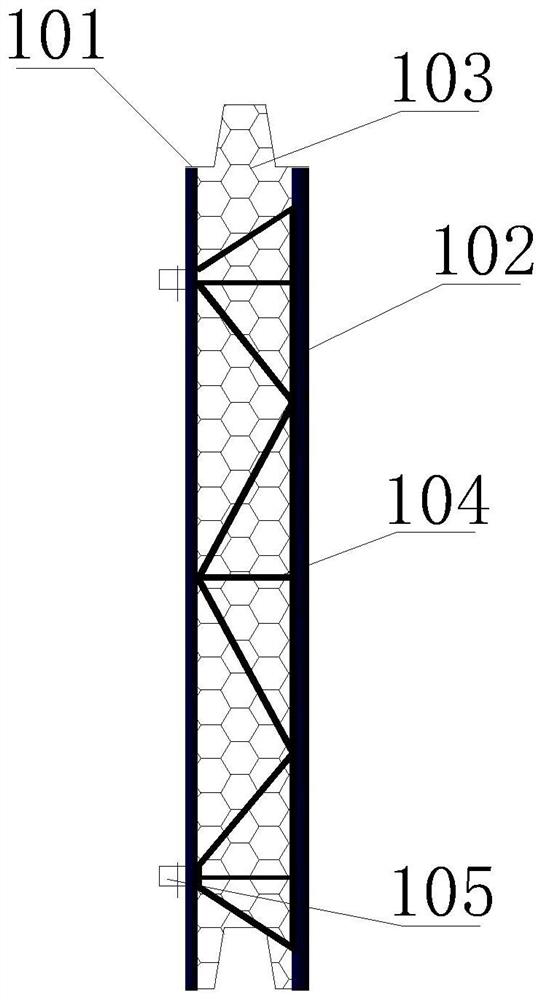

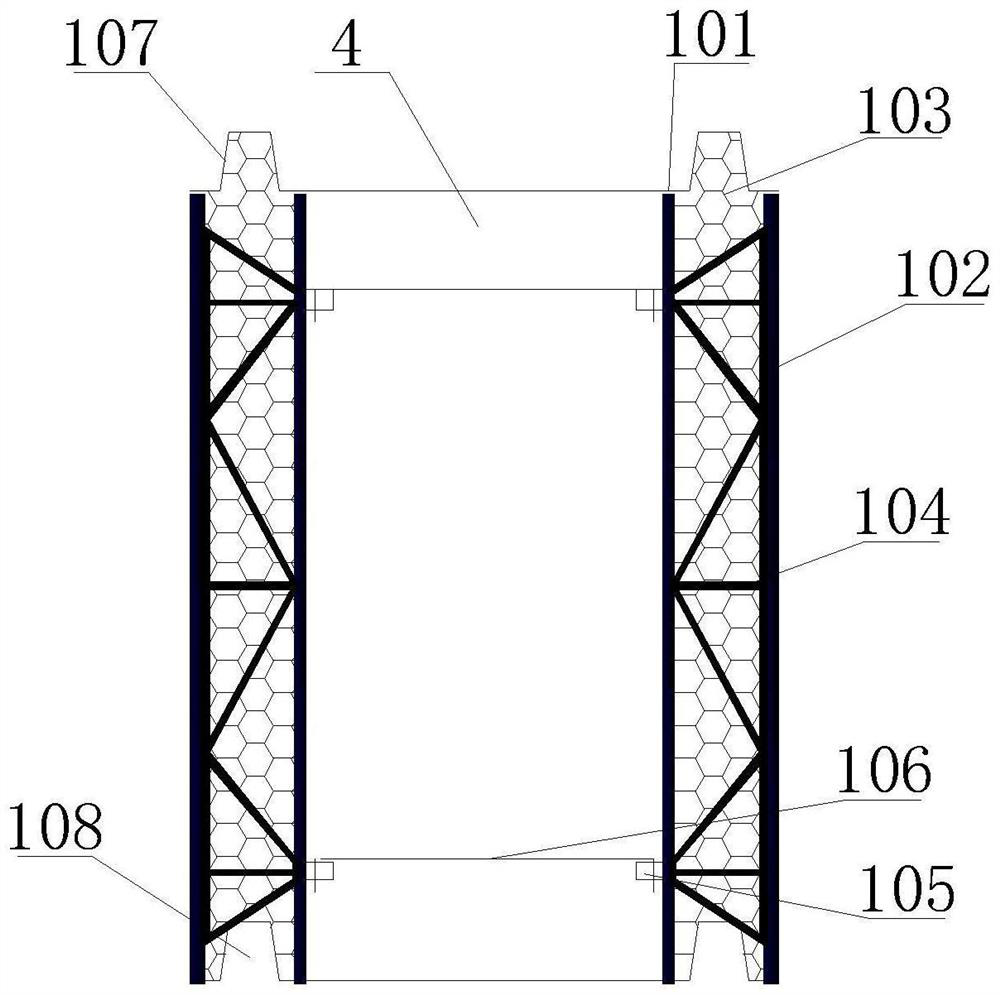

[0032] This embodiment provides a composite formwork 1 that adopts an inner pull type without dismantling, such as figure 1 As shown, it includes a module inner board 101, a module outer board 102 and a module core board 103 arranged between the module inner board 101 and the module outer board 102. The module core board 103 is embedded with an inner puller 104, and the inner puller 104 A connection part 105 protruding from the module inner panel 101 is provided on the top, and a structural tie rod 106 is connected between the inner formwork and the outer formwork constituting the building wall, and the two ends of the structural tie rod 106 are respectively connected to the inner formwork and the outer formwork. The connecting portion 105 on the layer template, the two sides and the upper and lower sides of the module core board 103 are respectively provided with slots 107 or sockets 108 for splicing connection with other composite templates.

[0033] In this specific embodim...

Embodiment 2

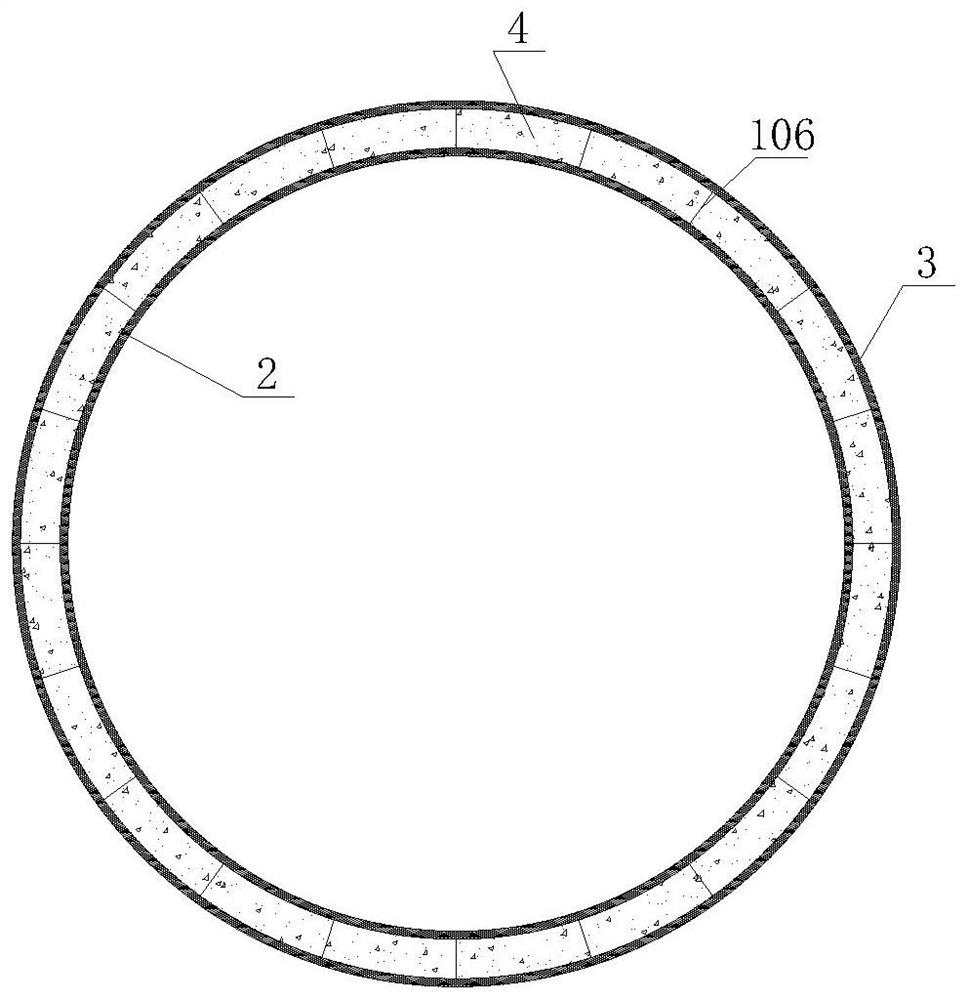

[0036] On the basis of Embodiment 1, this embodiment provides a concrete cylinder wall, such as figure 2 , image 3 As shown, it includes the inner wall 2 and the outer wall 3, and the concrete pouring cavity 4 is between the inner wall 2 and the outer wall 3, and the inner wall 2 and the outer wall are all spliced by the inner pull type non-detachable composite template 1 in the first embodiment. Since the wall of the cylinder is circular, the inner pull type non-disassembly composite formwork 1 is a curved formwork, and the inner wall of the cylinder and the outer wall 3 of the cylinder are connected by a structural tie rod 106, and the two ends of the structural tie rod 106 are respectively connected to the inner pull On the connection part 105 of the non-disassembly composite formwork 1.

Embodiment 3

[0038] This embodiment provides a construction method for the concrete cylinder wall in Embodiment 2, specifically as follows:

[0039]1) After the foundation construction of the cylinder body is completed, before the construction of the cylinder body, the contact surface between the cylinder body foundation and the cylinder body should be chiseled and cleaned. The central control piles should be manufactured and installed and marked for protection. After the binding steel bars are concealed and accepted, support The inner-pull non-dismantling composite formwork 1, after the inner-pull non-dismantling composite formwork 1 is supported to the pouring height, the concrete is poured, and after the first layer of concrete is poured and reaches a certain strength, the upper second layer of concrete is poured Pouring construction, repeating this cycle until the cylinder body is poured to the top;

[0040] 2) Assemble the inner wall 2 and the outer wall 3 of the cylinder body with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com