Rail fence fire barrier and method for manufacturing same

A manufacturing method and flame arrester technology, which are applied in the directions of machines/engines, fuel air intakes, mechanical equipment, etc., can solve problems such as economic decline, increase in exhaust pollutant emissions, and increase in intake and exhaust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

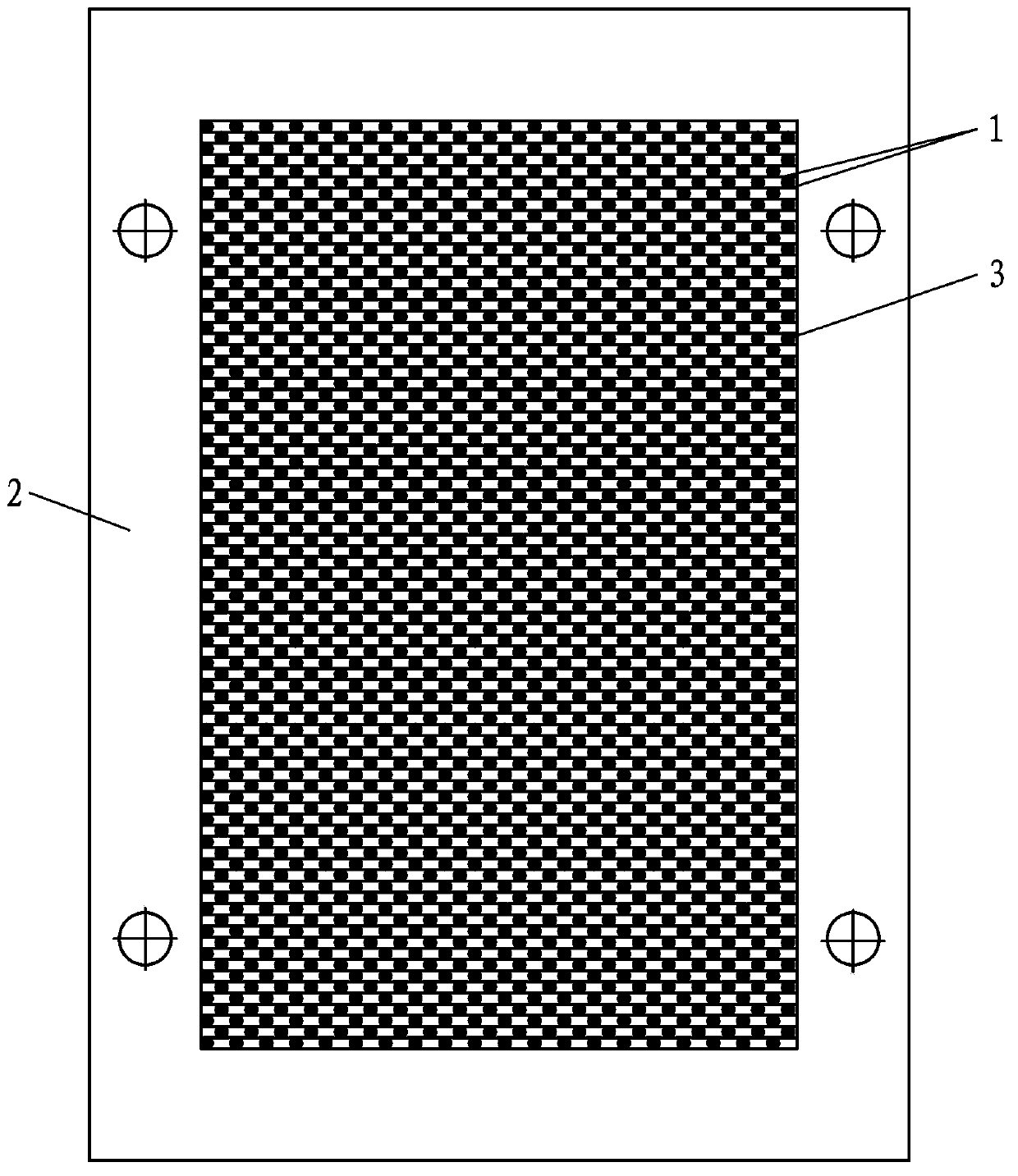

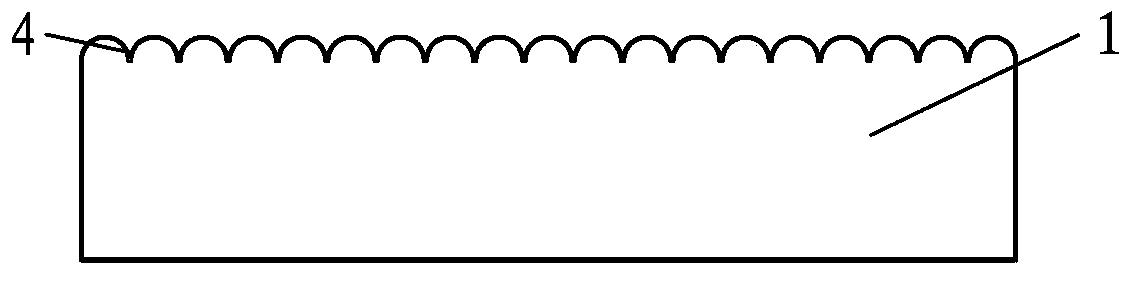

[0017] Such as figure 1 As shown, a kind of fence flame arrester of the present invention comprises some fence pieces 1, some steel wires 3 and flame arrester frame 2, and the material of fence piece 1 and steel wire 3 is stainless steel, and the number of fence pieces 1 and steel wire 3 is determined by the area of flame arrester size to decide. The two ends of the fence pieces 1 are welded in parallel on the inner wall of the flame arrester frame 2 in turn, and there is a certain interval between adjacent fence pieces 1, and the interval is not more than 0.5mm. Such as figure 2 As shown, one side edge of the fence piece 1 is toothed, and the toothed edges of two adjacent fence pieces 1 face opposite directions. The diameter of the steel wire 3 is 0.4mm. The steel wire 3 bypasses the fence piece 1 sequentially from bottom to top, and is stuck in the tooth groove 4 on the edge of the fence piece 1. The two ends of the steel wire 3 are fixedly connected to the fence piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com