Lubricating device for power transmission mechanism

A power transmission mechanism and lubricating device technology, applied in the direction of gear lubrication/cooling, etc., can solve the problems of guide tube damage, difficulty in supplying lubricating oil to the position where it should be supplied, guide tube swing, etc., and achieve the effect of improving accuracy and inhibiting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

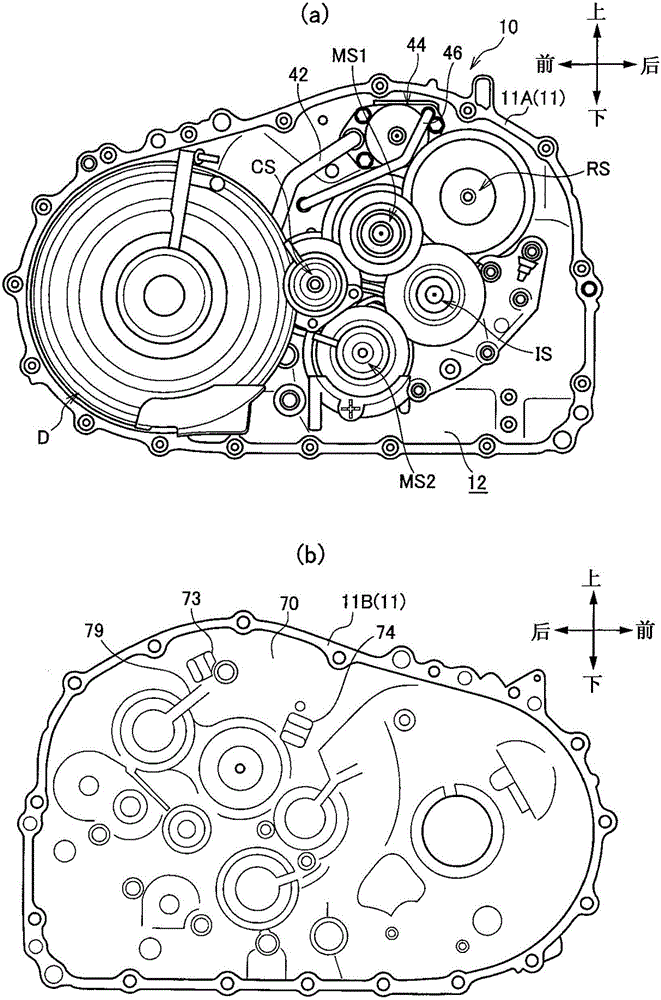

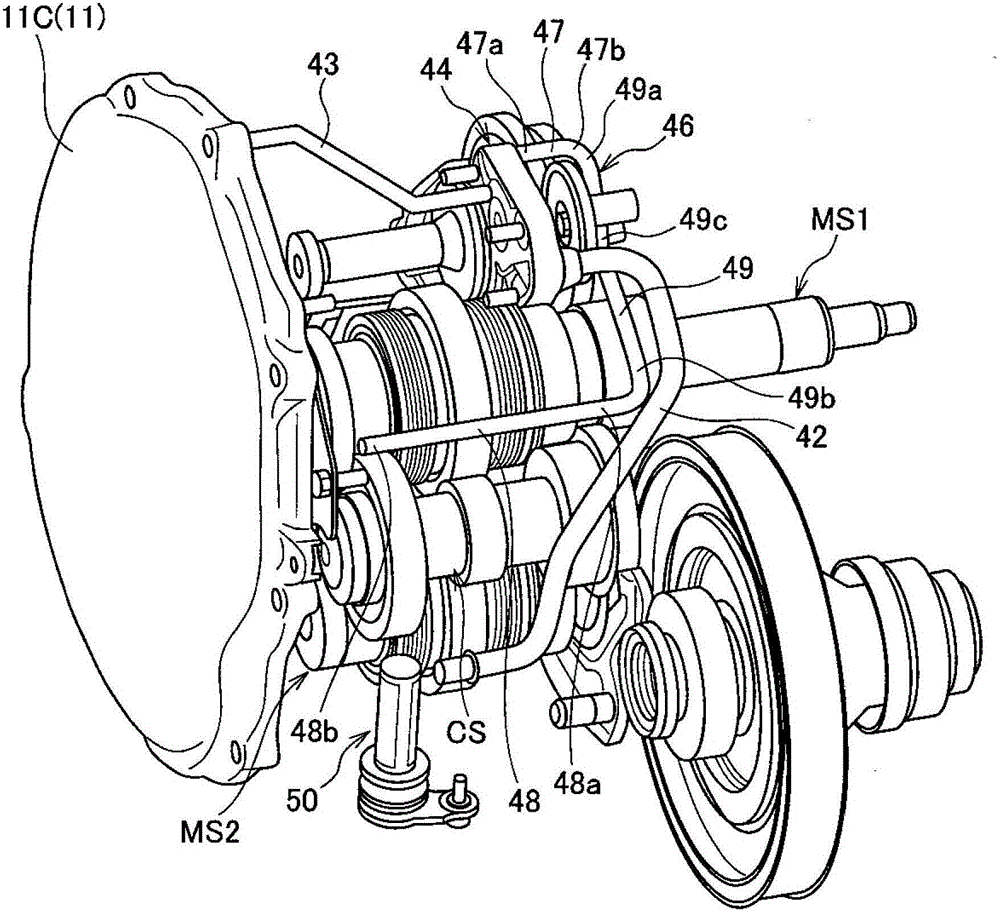

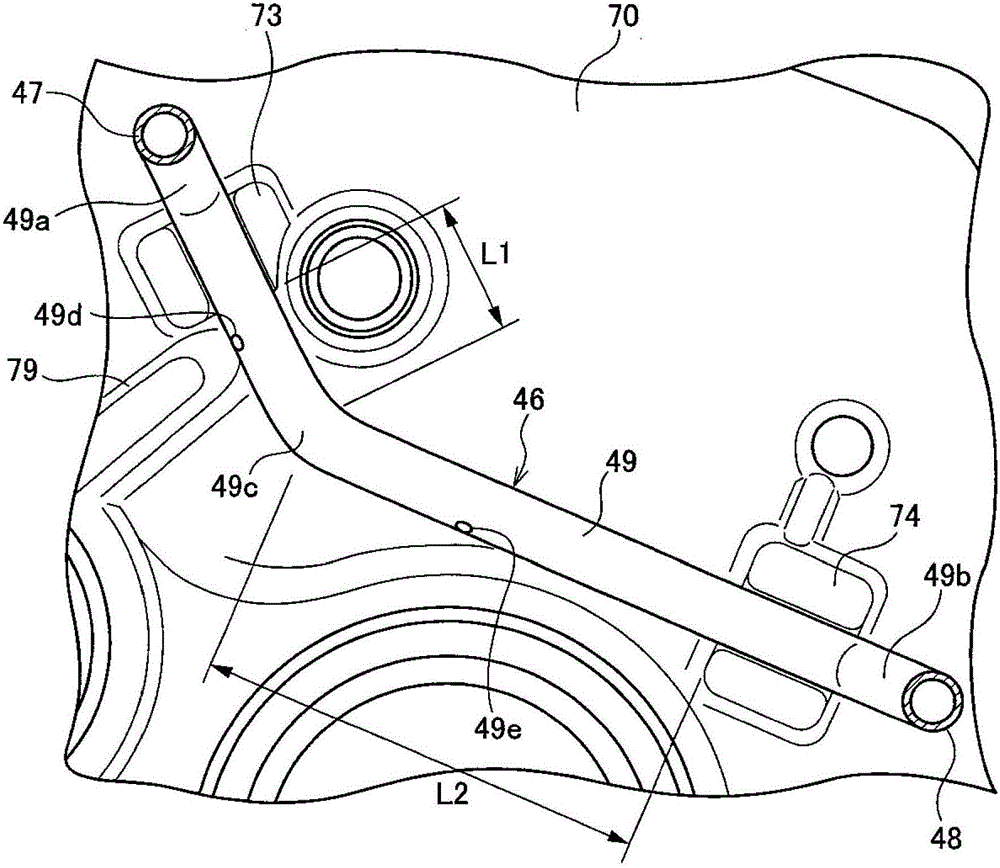

[0047] Below, based on Figure 1 to Figure 5 One embodiment of a lubricating device for a power transmission mechanism (hereinafter referred to as a transmission) of the present invention will be described.

[0048] Such as figure 1 and figure 2 As shown, the transmission 10 for a motor vehicle is provided with a speed change mechanism and a motor not shown in the inside of the transmission case 11 formed by the first case 11A, the second case 11B, and the side cover 11C. The speed change mechanism consists of It is composed of a first main shaft MS1, a second main shaft MS2, an idler shaft IS, an intermediate shaft CS, a reverse shaft RS, and a differential device D whose rotation axes are perpendicular to the plane of the paper. A motor (not shown) is disposed between the transmission mechanism and the side cover 11C so as to be adjacent to the transmission mechanism. and, if figure 1 As indicated by the arrows in , the transmission 10 is arranged so that the vertical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com