hood latch

A technology for a hood and a latch device, applied in the field of latch devices, can solve the problems of difficulty in maintaining the engagement state of the ratchet and the latch, and achieve a strong effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

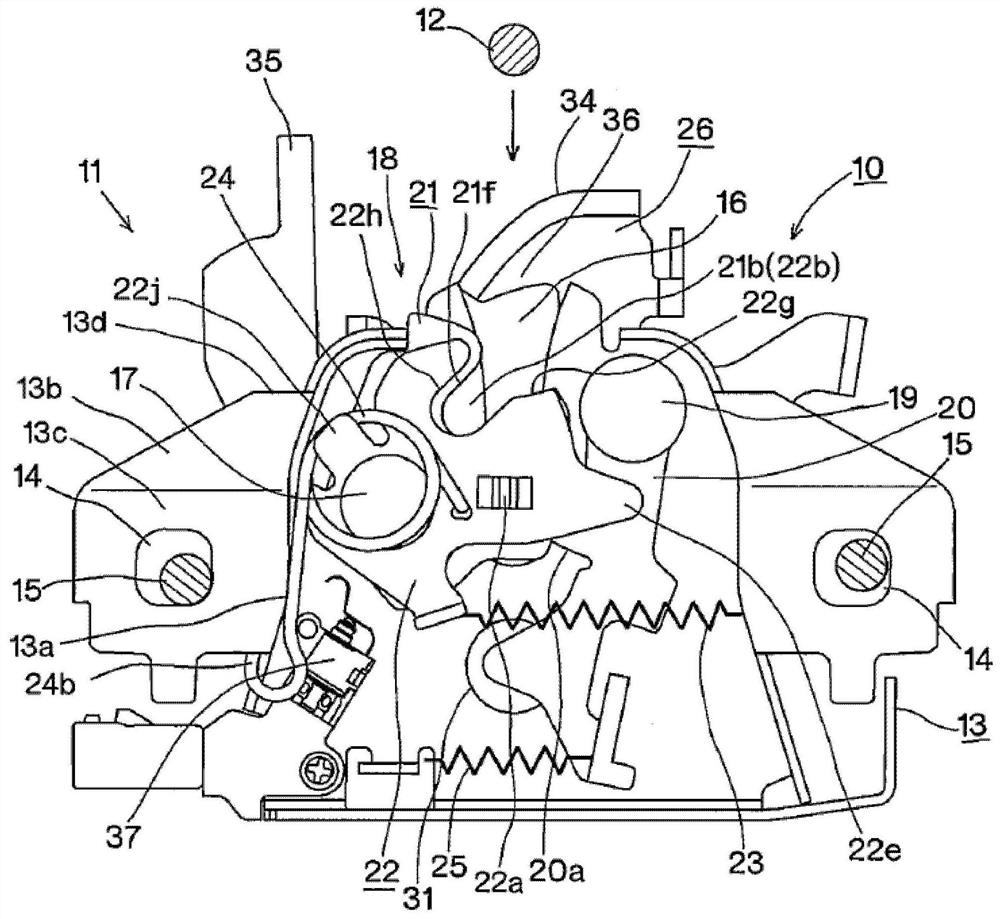

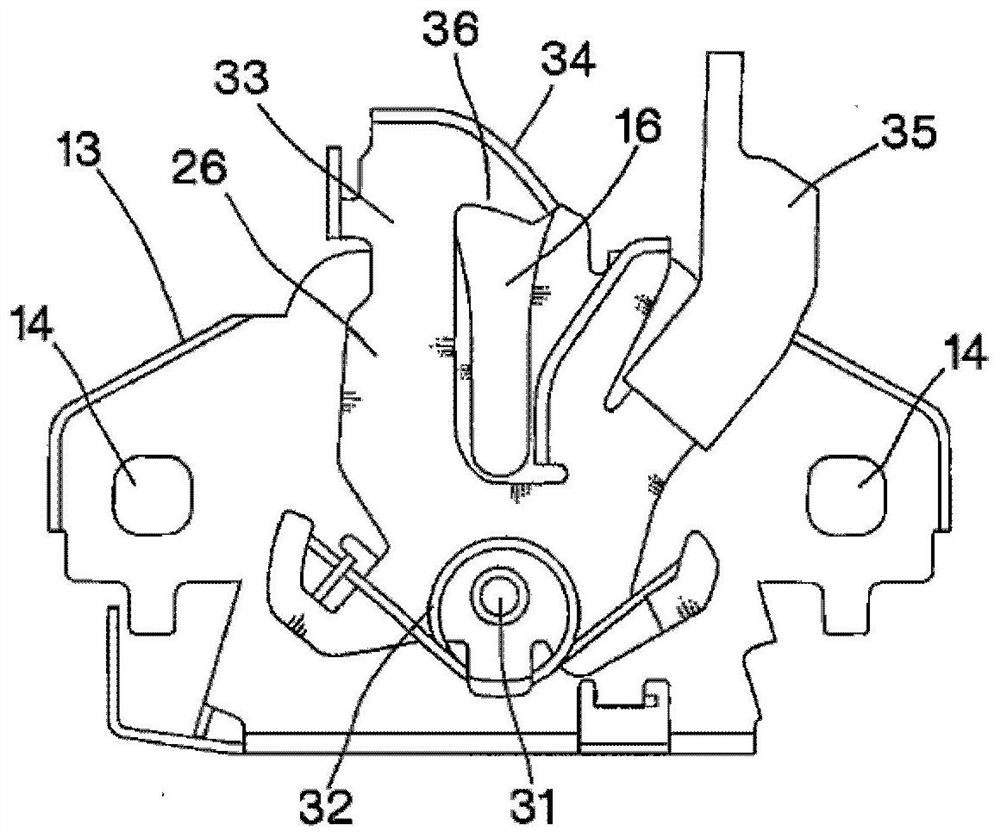

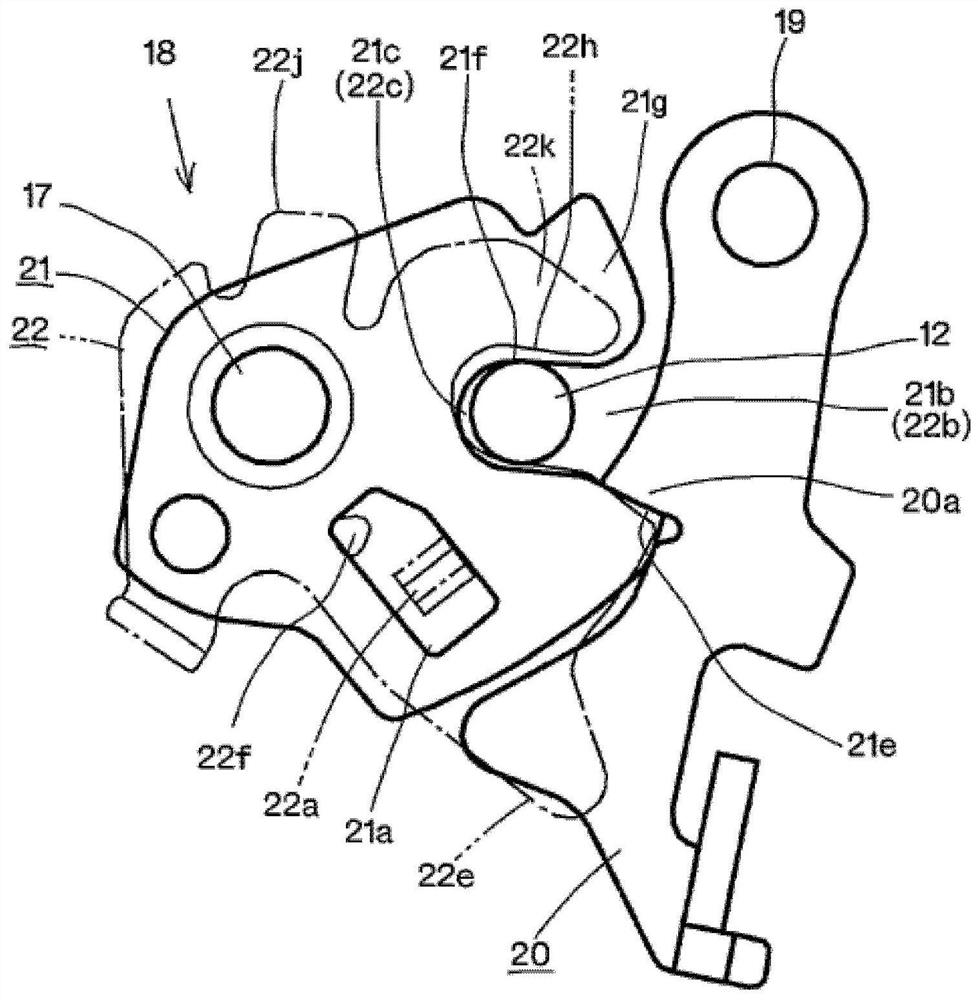

[0039] Embodiments of the present invention will be described with reference to the drawings. figure 1 The front of the hood latch device 10 of the illustrated embodiment is shown. In many vehicles, an engine room is arranged in the front portion of the vehicle compartment, and a typical hood (not shown) covering the engine room has a rear end portion (base end portion) axially supported on the vehicle body by hinges or the like. ). The hood latch device 10 includes a latch unit 11 fixed to the front end of the vehicle body and a striker 12 fixed to the front end (rotation end) of the hood.

[0040] as in figure 1 and 2 As shown in , the latch unit 11 includes a metal substrate 13 . Rectangular attachment holes 14 are formed on both left and right sides of the substrate 13 . The attachment hole 14 is formed sufficiently larger than the shaft diameter of the bolt 15 inserted into the attachment hole 14 , and the attachment position of the latch unit 11 is finely adjusted by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com