Hydraulic hose tee joint

A technology of three-way joints and hydraulic hoses, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, passing components, etc. It can solve the problems of unevenness, poor tightness of rubber gaskets, oil leakage, etc., and achieve improvement Misalignment, ideal sealing effect, and good tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

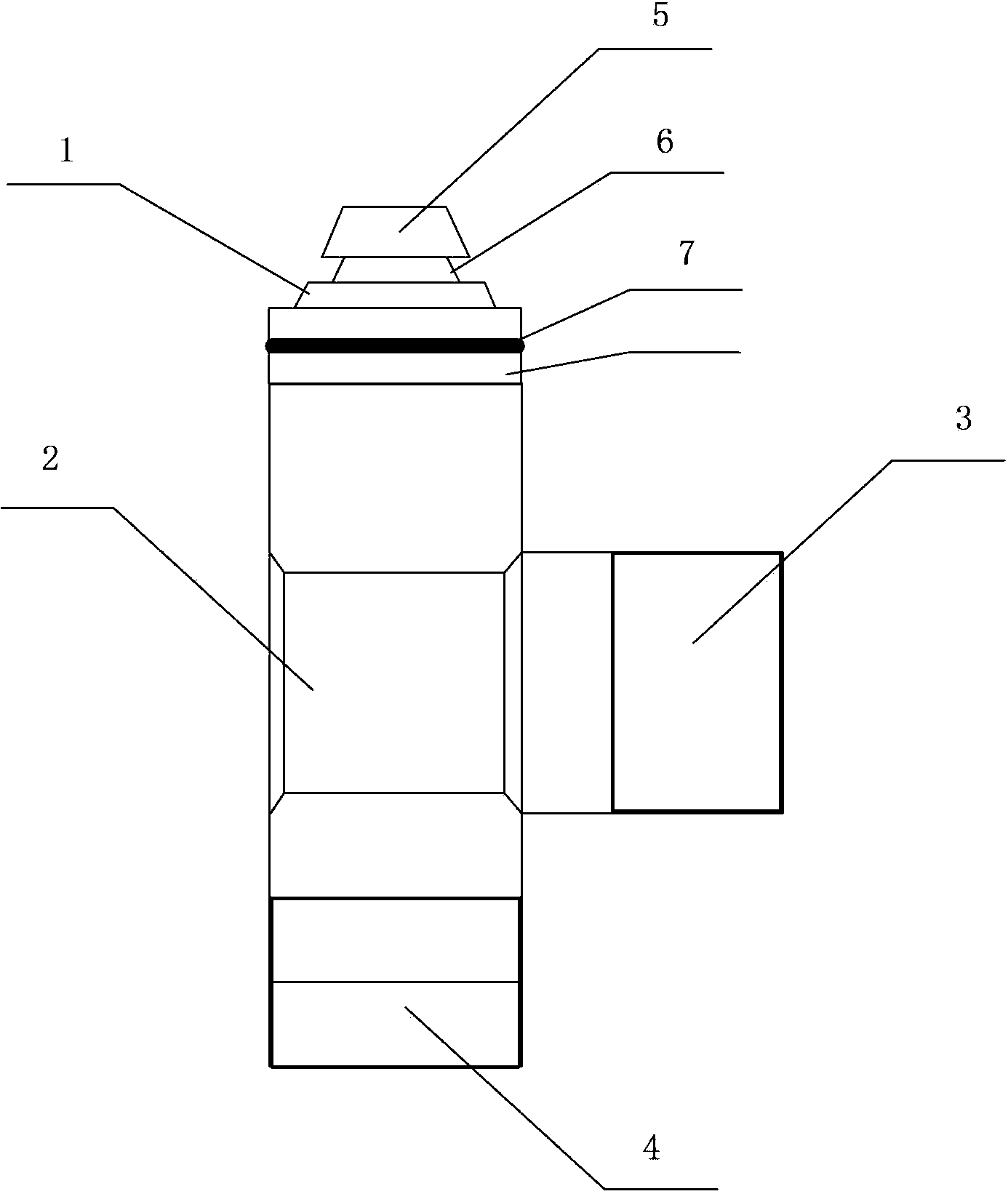

[0012] As can be seen from the figure, the present invention includes passageway I4, passageway II3, joint body 2, and passageway III1, wherein the end of passageway III1 is provided with an inner nozzle, and the shape of the inner nozzle is a tapered structure that gradually shrinks toward the end, and its outer wall is extended The angle between the lines is 24°±30′, and an annular groove 6 is provided near the end.

[0013] The connection mode of the hydraulic hose tee joint of the present invention is that passage I4 and passage II3 are connected to the joint body 2 at 90 degrees, and passage II3 and passage III1 are connected to the joint body 2 at 90 degrees, and the three are all on the same plane. The specific structure of the joint body III1 part is divided into the internal structure and the nut. The internal structure includes the beginning of the inner joint 8, the steel wire 7, the annular groove 6, and the end of the inner joint 5. An O-ring is added to the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com