Lamp shell and gap-variable hinge

A variable gap and hinge technology, which is applied in the field of lighting, can solve problems such as the offset between the upper shell and the lower shell and affect the sealing of the lamp, and achieve the effects of flexible rotation, accurate positioning, and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and embodiments.

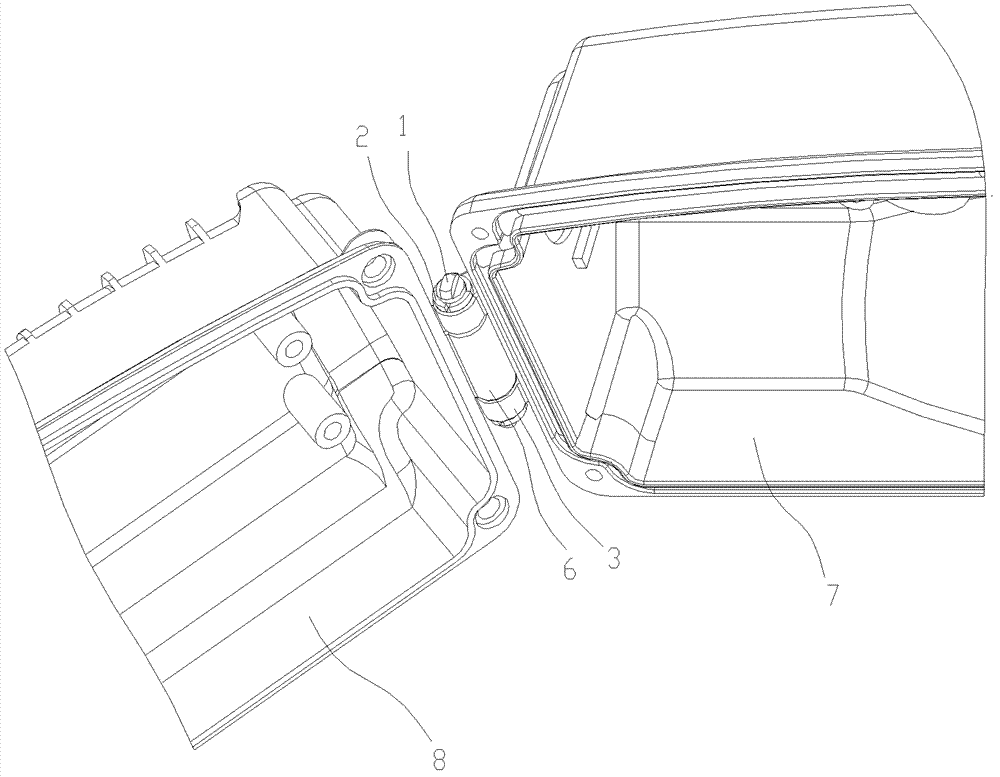

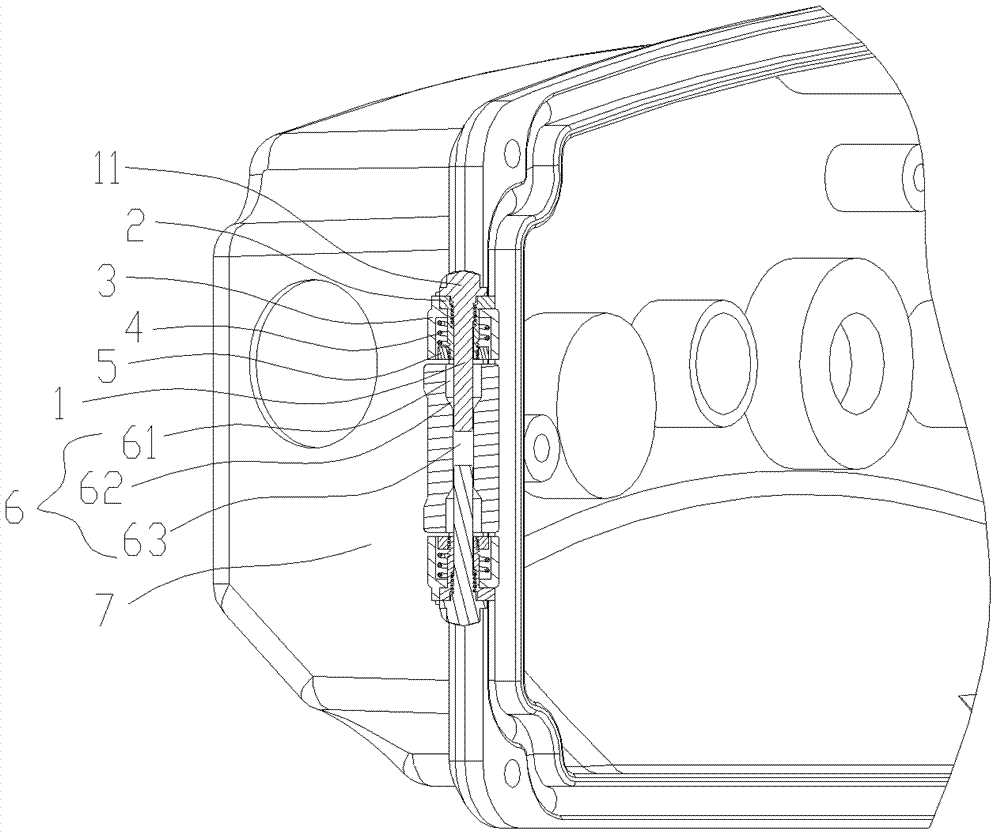

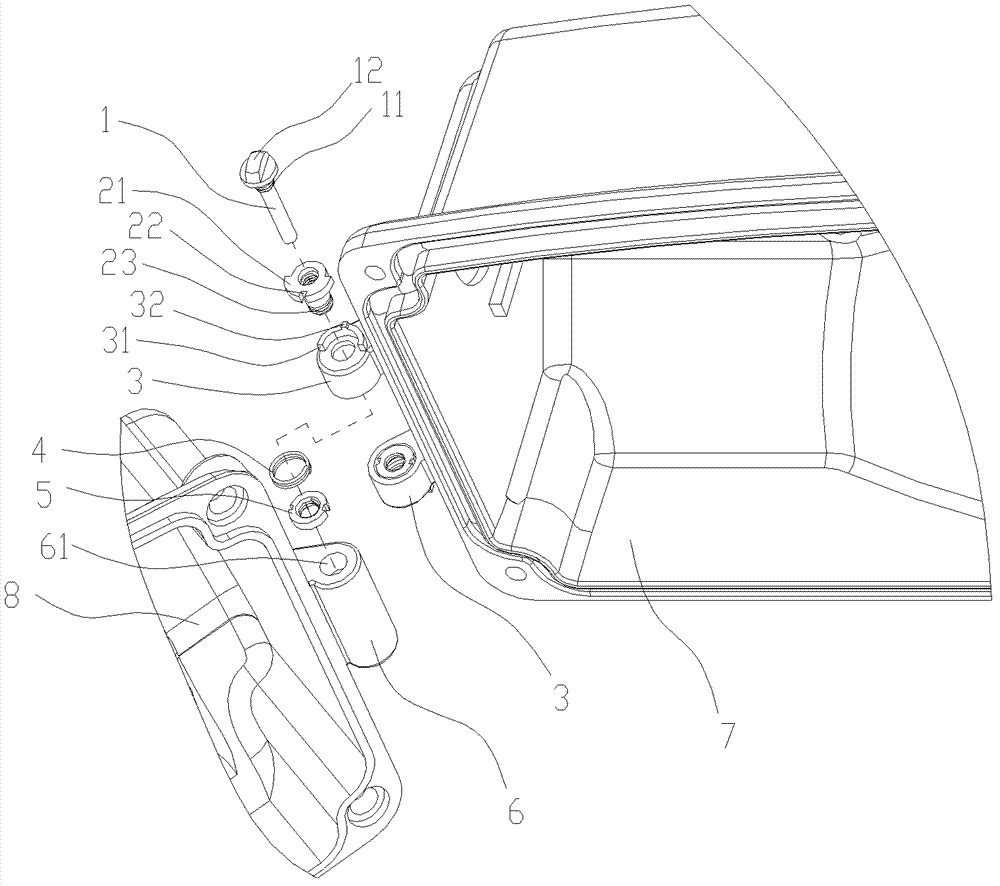

[0022] The structure of the embodiment of the lamp housing and the variable gap hinge of the present invention is as follows: figure 1 , figure 2 and image 3 As shown, the figure includes two pin shafts 1, two positioning sleeves 2, two pin shaft seats 3, two return springs 4, two spring glands 5, a hinge seat 6, and an upper shell 7 and a lower shell 8.

[0023] In the figure, the variable clearance hinge hinges the upper shell 7 and the lower shell 8 of the lamp housing together. The hinge seat 6 of the variable gap hinge is connected with the lower shell 8, and the hinge seat 6 is located in the middle of the edge side of the lower shell 8; the pin seat 3 of the variable gap hinge is connected with the upper shell, and the pin seat 3 is l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap