Swirler for combustion chambers

A swirler, fluid technology, applied in the field of burners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] When introducing elements of various embodiments of the invention, "a," "an," "the," and "said" are intended to mean that there are one or more of the elements. The terms "comprising" and "having" are intended to be inclusive and mean that there may be other elements other than the listed elements. Any examples of operating parameters are not meant to exclude other parameters of the disclosed embodiments.

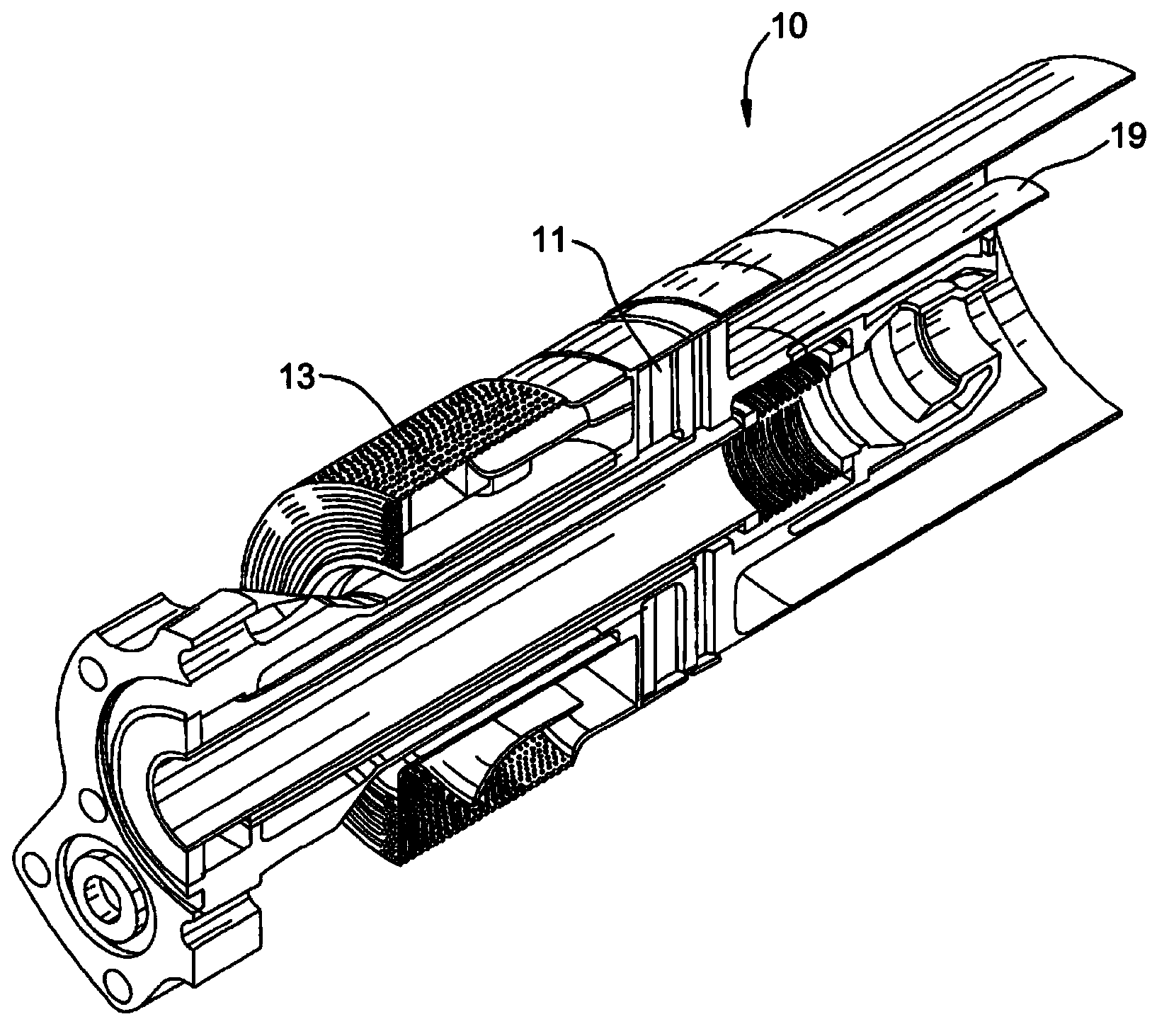

[0027] figure 1 Shown is a portion of a fuel nozzle 10 including a combustion swirler 11 in accordance with an embodiment of the invention. The combustion swirler 11 is configured to receive a flow of combustion fluid, typically air, from a nozzle inlet 13 of the gas turbine and to mix the air with fuel into an air-fuel mixture. The air-fuel mixture then travels downstream for ignition in combustion zone 19 .

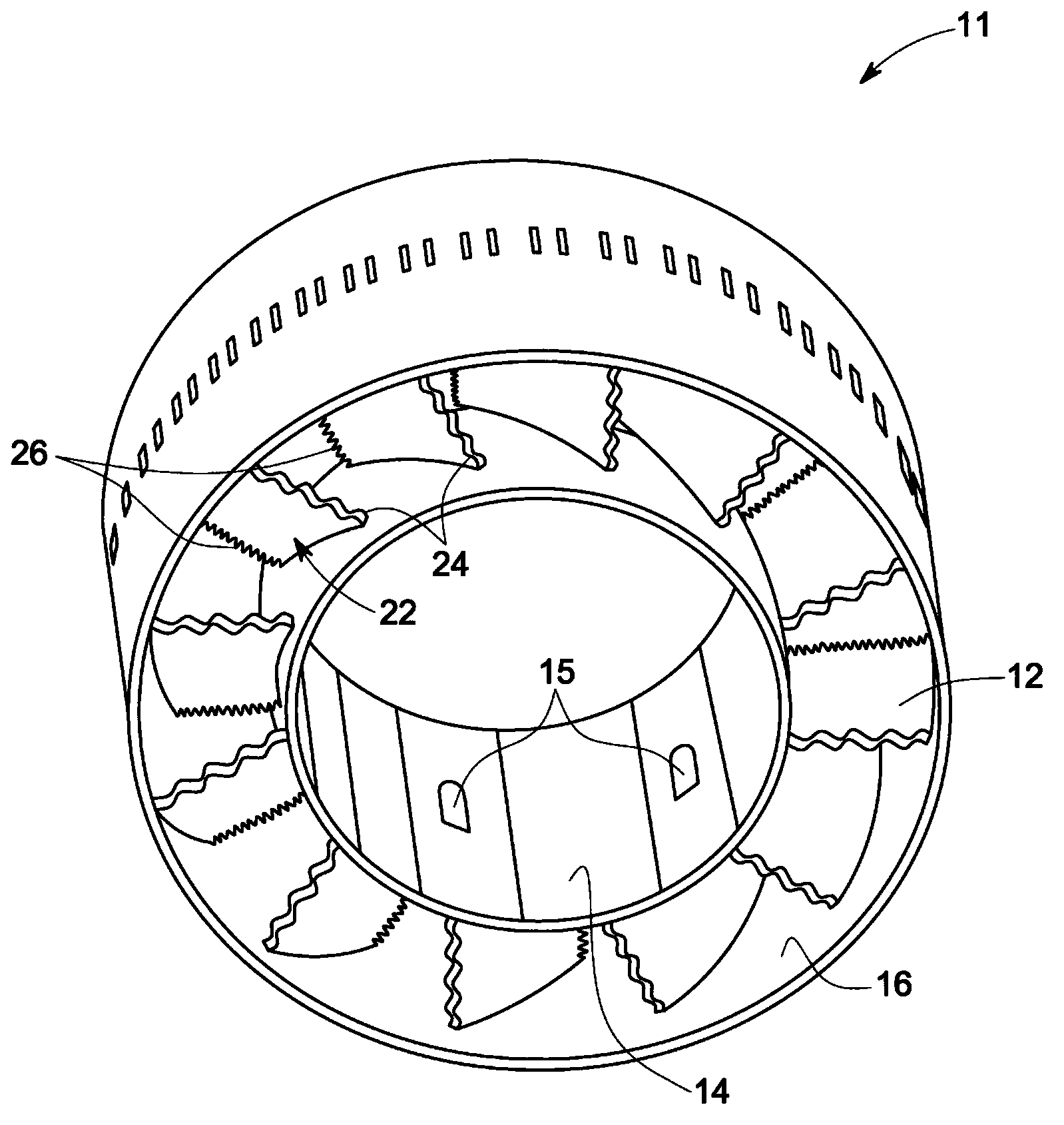

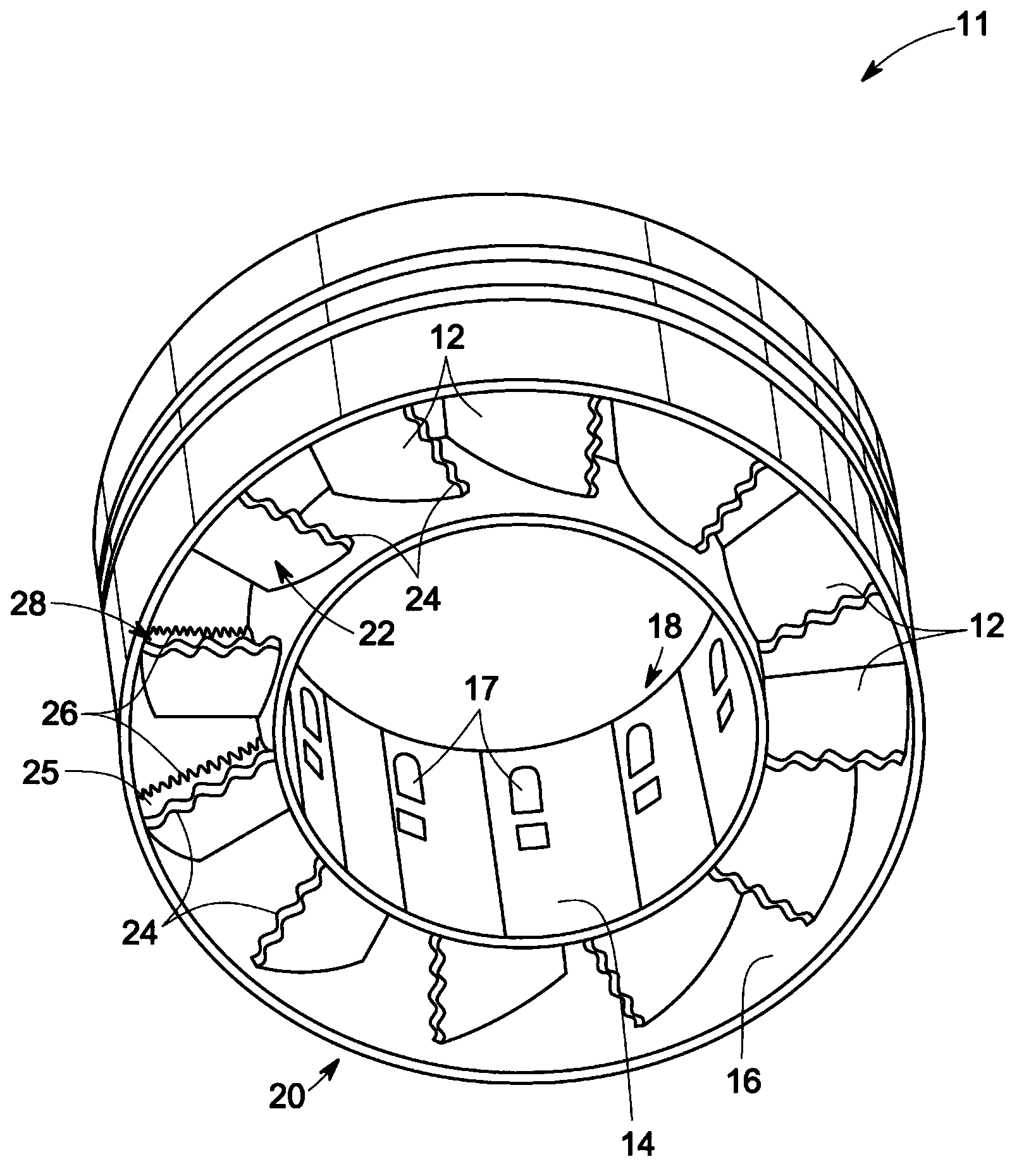

[0028] figure 2 Shown is a perspective view of a combustion swirler 11 according to an embodiment of the invention. As shown, the combustion swirler 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com