Four-axis movement control carrying device

A motion control and motion technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of hoisting equipment damage, low degree of automation, single movement mode, etc., and achieve the effect of easy installation, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

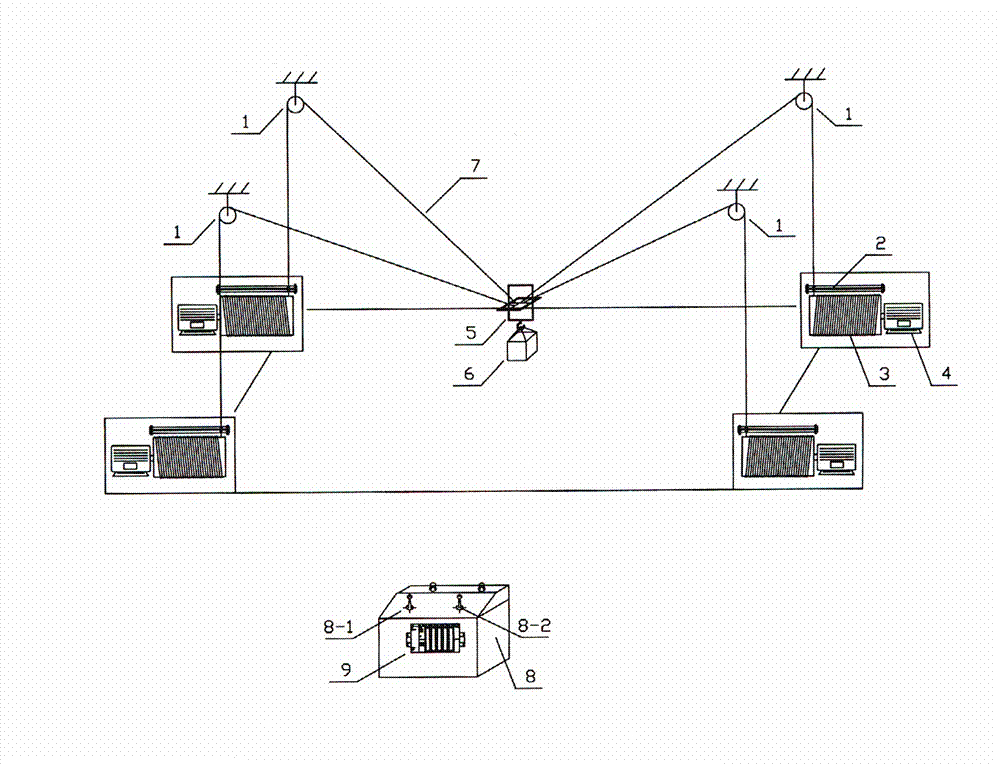

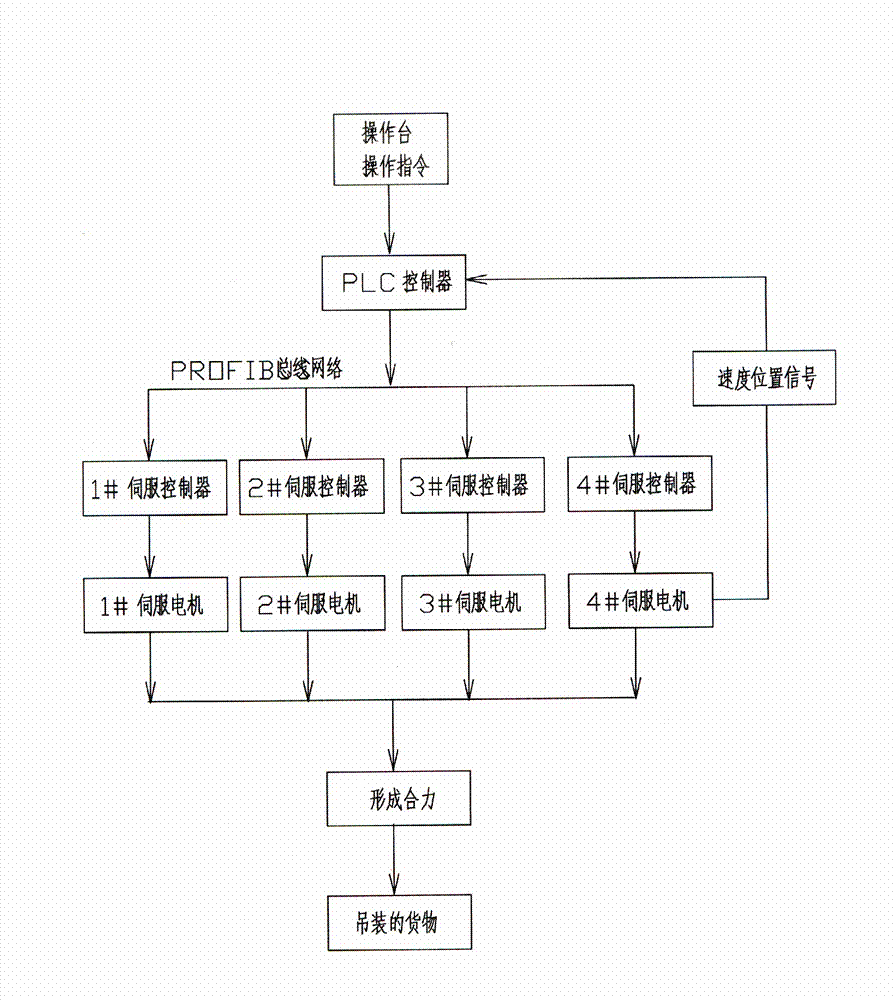

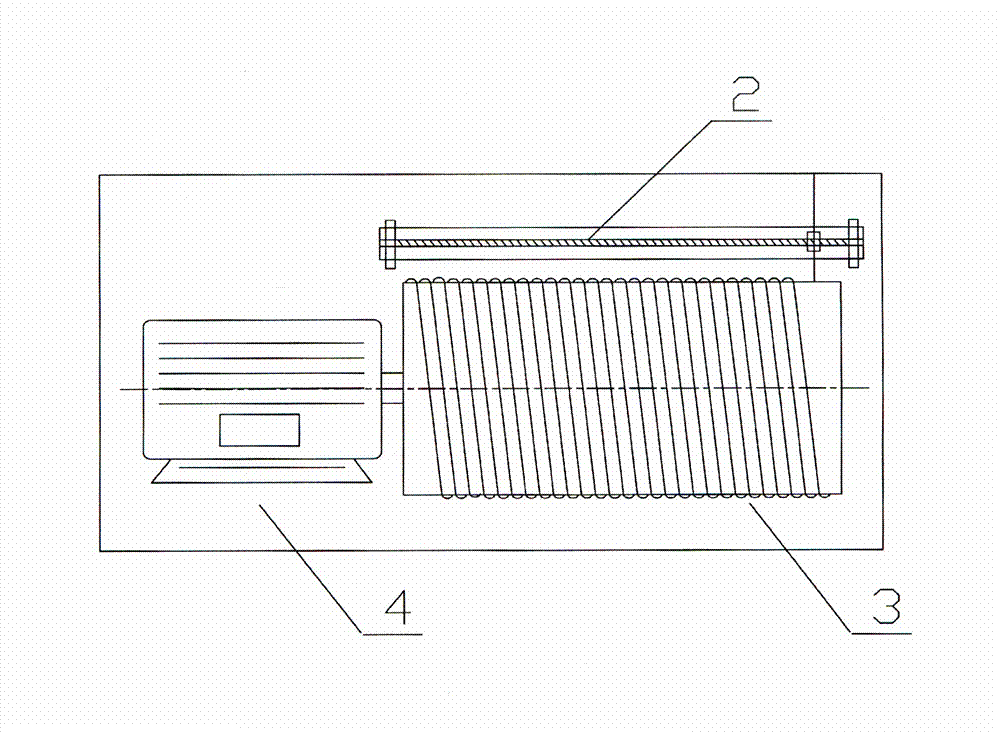

[0029] Such as figure 1 As shown, the servo motor 4 is used as the power of the hoisting device 3, and is located at the four corners of the four sides of the construction site. A fixed pulley 1 is fixedly installed at the same height above it, and the steel wire rope 7 on the hoisting device 3 passes through the fixed pulley. After 1, they are collected on the carrying device 5 platform, and the lifted cargo 6 that is moved is suspended on the carrying device 5 platform. The hoisting goods 6 to be moved are suspended by four steel wire ropes 7. After the four steel wire ropes 7 pass through the fixed pulley 1, they are wound on the four hoisting devices 3, and the hoisting device 3 is driven by the servo motor 4 to make the hoisting goods 6. Perform movement in accordance with the operating direction of the operator. The hoisting goods 6 can move up, down, left, right, front, back, or obliquely, curved lines, etc. in this interval, and the four servo motors 4 can realize fas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap