Four-axis movement control loading device

A motion control and motion technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of inability to disassemble and install in a large space, and achieve the effect of easy installation, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] In the specific implementation, we divide it into the following two parts according to the implementation case:

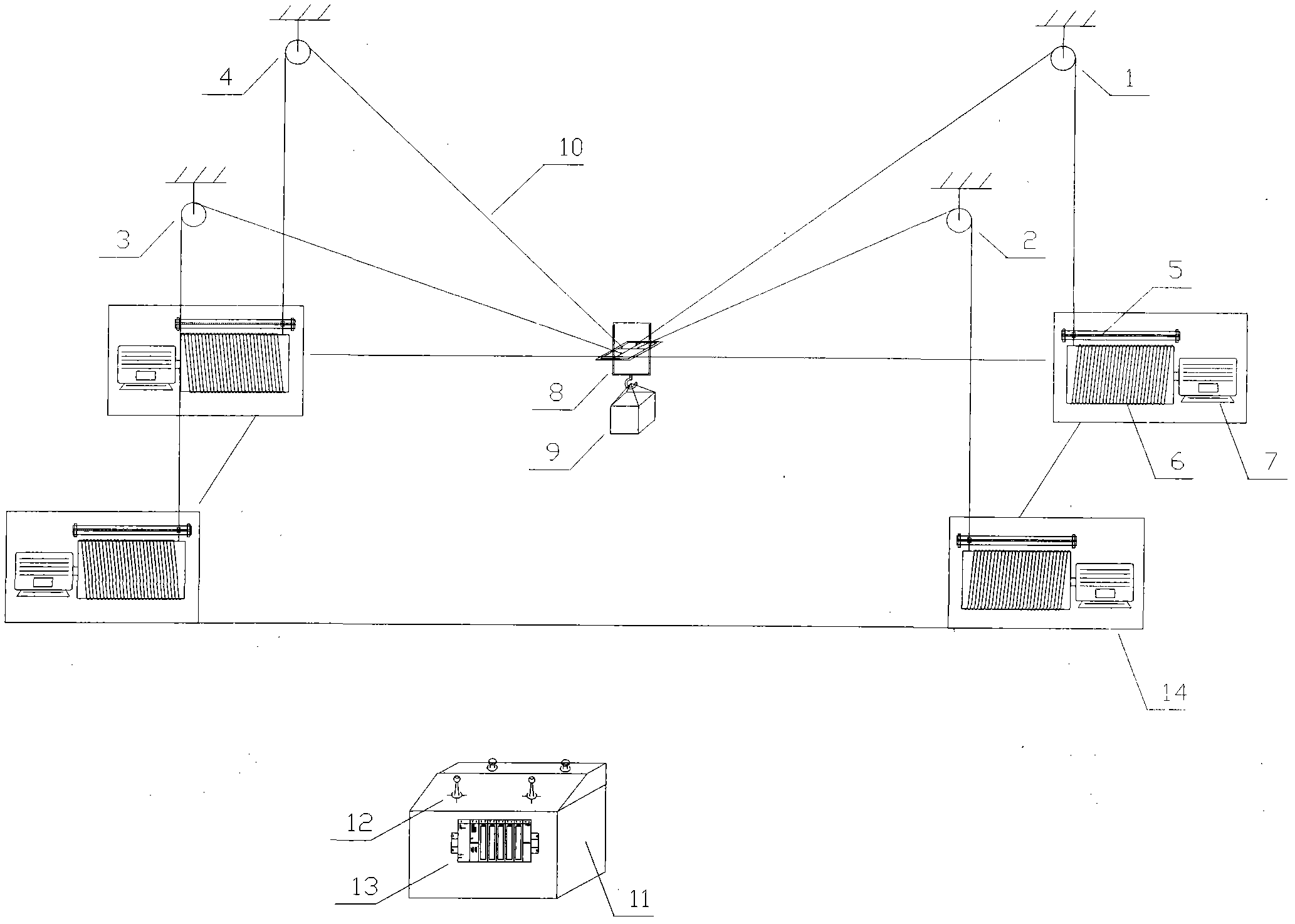

[0036] 1. Mechanical equipment

[0037] The mechanical equipment includes hoisting equipment, fixed brackets, cables and ropes and other equipment. After our design and calculation, the German Siemens 1FK series servo motor is selected as the power element in our system. According to the calculation, different weights are selected. Different motor powers The size has been the size of a wire rope. This manual is a small-scale research and development equipment. In the future, large-scale series equipment will be developed and designed according to the mode of this system, so this system is not limited to one size.

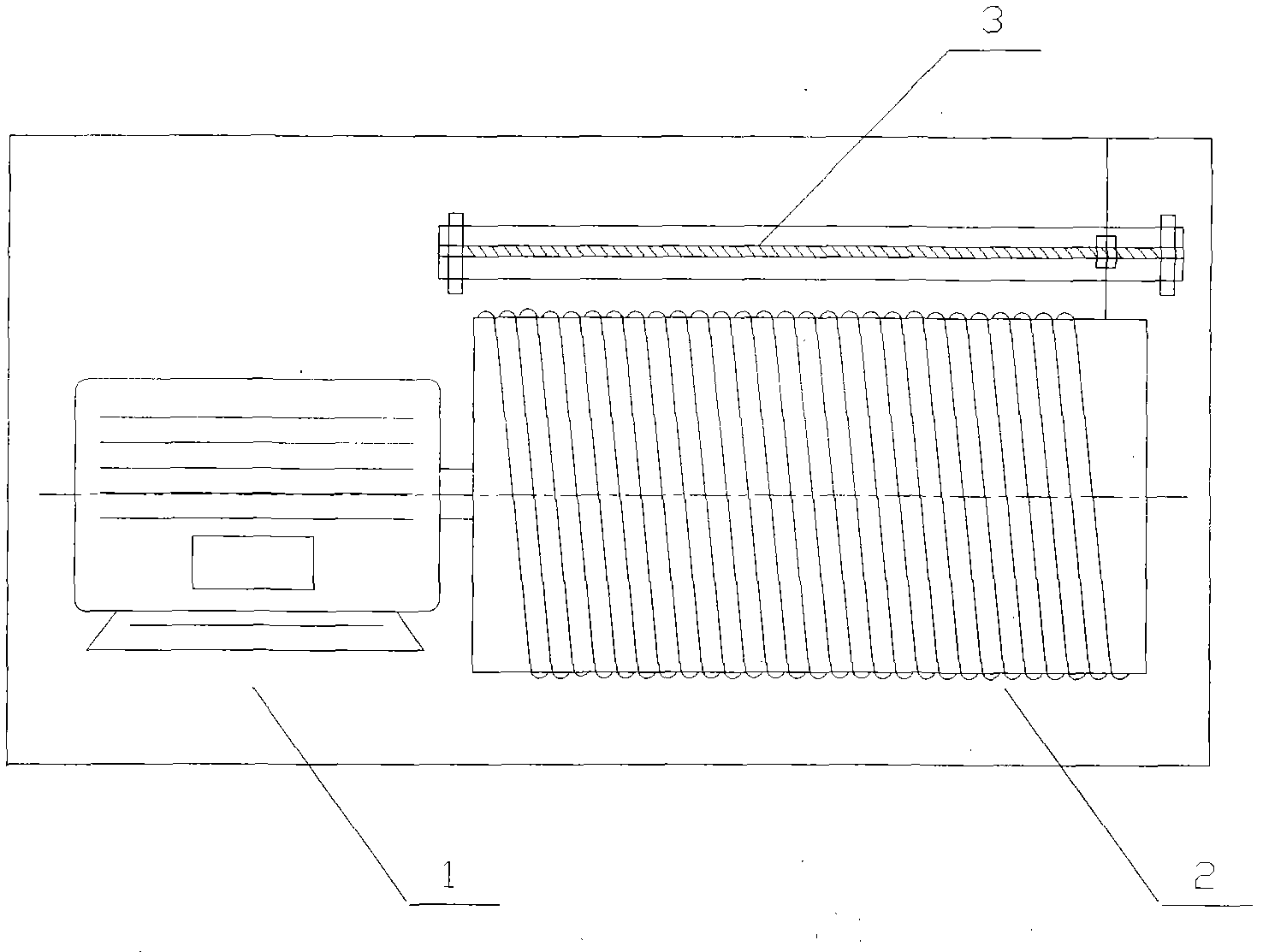

[0038] image 3 It is the connection diagram of the servo motor and hoisting equipment of this system

[0039]According to the size of the servo motor and the size of the force-bearing object, we designed the motor and hoisting equipment cabine...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap