Drop-out fuse

A drop-out fuse and fuse technology, which is applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve problems such as mechanical damage to fuses, abnormal opening of fuses, abnormal power supply, etc., and achieve protection against mechanical damage. Damage, guaranteed normal use, easy to process and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

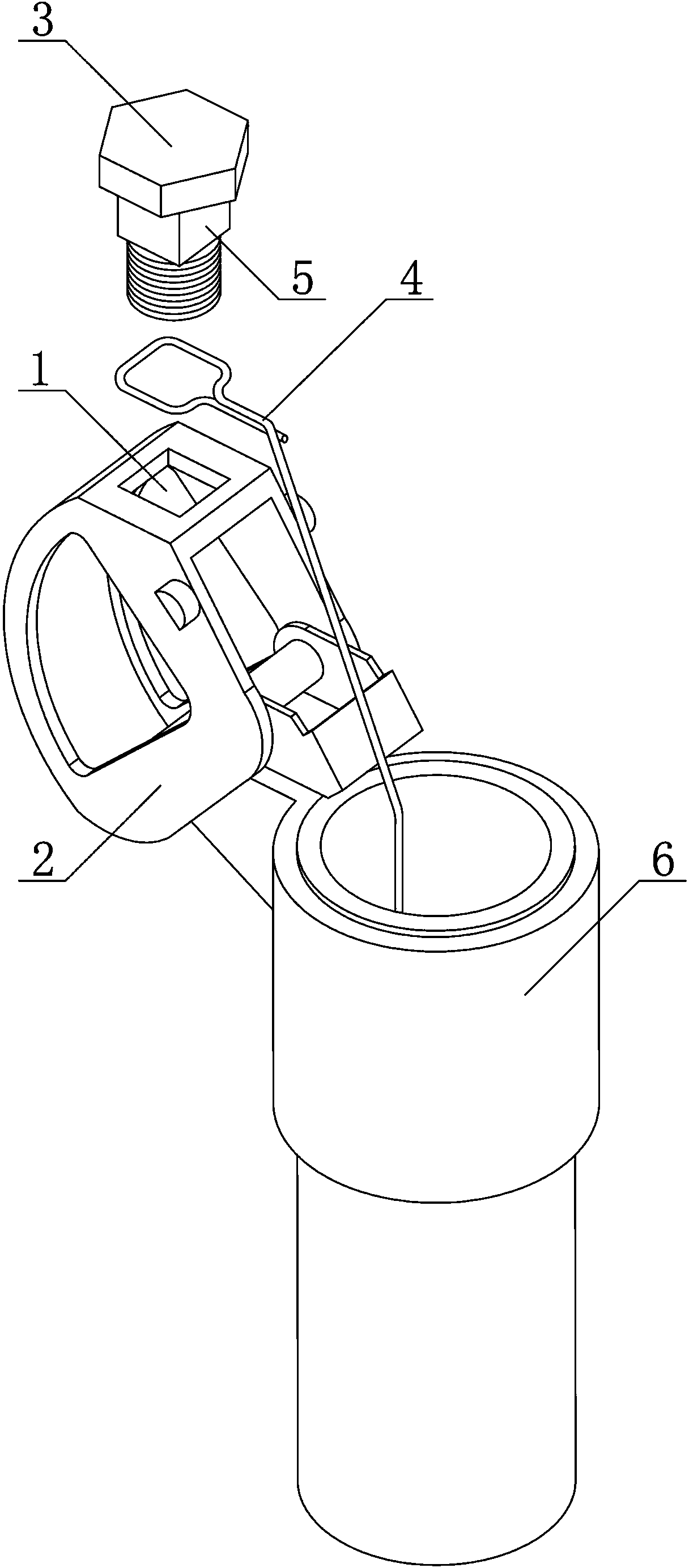

[0014] Such as figure 1 As shown, a drop-out fuse includes a lower moving contact 2 with a fixing hole 1, a bolt 3 arranged in the fixing hole 1, and a fuse 4 installed on the bolt 3; the fixing hole 1 The radial cross-section is non-circular, and a post 5 corresponding to the shape of the fixing hole is arranged between the bolt head of the bolt 3 and the bolt screw, and the fuse 4 is wound on the post 5, The post 5 is inserted into the fixing hole 1 . The advantage of this design is: due to the non-circular row design, the clamping post 5 can only move axially and cannot rotate radially in the fixing hole 1, so when the bolt 3 is fixed with a nut, it is wound around the The fuse 4 on the clamping column 5 can only be subjected to the pressure from the bolt head and the lower moving contact 2, and will not be subjected to rotational friction, effectively avoiding the damage caused by the rotational friction to the fuse 4. Mechanical damage ensures the normal service life of...

Embodiment 2

[0018] The difference between embodiment 2 and embodiment 1 is that the radial section of the fixing hole is elliptical, and the clamping column is an elliptical clamping column. This design provides a cross-sectional shape different from polygonal, which can achieve Same effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com